The Lost Recipe of Self-Healing Concrete: A Maintenance Dream

Natalie Johnson

Posted 06/01/2023

Enduring nearly 2,000 years of foot traffic, harsh weather, and earthquakes the Pantheon is one of the most impressive structures in the world. Modern concrete structures only last an average of 100 years, assuming proper maintenance is regularly performed. Yet the Romans were able to create a material that has the ability to heal small fissures on its own, allowing their infrastructure to withstand the test of time. Being that concrete is the most commonly used building material in the world, scientists have been searching for the lost recipe to self-healing concrete for hundreds of years without success. Until now, when a team of scientists finally cracked the code.

Concrete Then and Now

The Pantheon is home to the largest unreinforced concrete dome in the world, measuring 142 by 71 feet. It was constructed in 125AD by Roman Architects and engineers and is only one of the many incredible structures built during the Roman Empire. Others include aqueducts, roads, and seawalls that are still standing today.

Modern concrete begins to crumble after 50 years as cracks and corrosion lead to degradation. Heavy structures and domes cannot be constructed without steel rebar, which helps enhance tensile strength. Without it, domes would collapse due to the weight of the concrete and small cracks that would form.

Steel rebar, however, comes with its own challenges as it begins to rust when moisture and water infiltrate concrete. This only leads to more cracks forming as the rust expands, a phenomenon known as oxide jacking.

The Romans were able to construct such impressive concrete structures that lasted over two millennia thanks to what’s known as self-healing concrete, a material that did not require reinforcement. Scientists have been trying to understand and replicate the recipe for decades.

The Quest

For years, researchers speculated that ox blood, urine, pottery chips, tobermite, and lime all had some influence on the self-healing abilities of Roman concrete, but they were unable to recreate a concrete that had the capacity to heal small fissures on its own. Many believed the recipe would be lost forever.

Admir Masic, a researcher from MIT, looked at the mystery from a different perspective and his inquisitions led to the discovery of the lost recipe.

He led a team of researchers from the US, Italy, and Switzerland to Privernum, Italy to study 2,000-year-old samples of Roman concrete from a city wall. The samples were compositionally consistent with other structures created during the Roman empire.

Masic and his team determined the unreinforced concrete used to construct the walls was created by mixing coarse aggregates (often ceramic fragments), volcanic ash or other pozzolana, sand lime, and water. This formula is consistent with previous research.

However, other researchers still couldn’t duplicate the self-healing abilities, even using the formula below. This led to speculation that the Romans unintentionally created this fascinating healing ability despite accounts from Roman Engineer, Vitruvius, emphasizing the limestone used must be pure white and lack impurities.

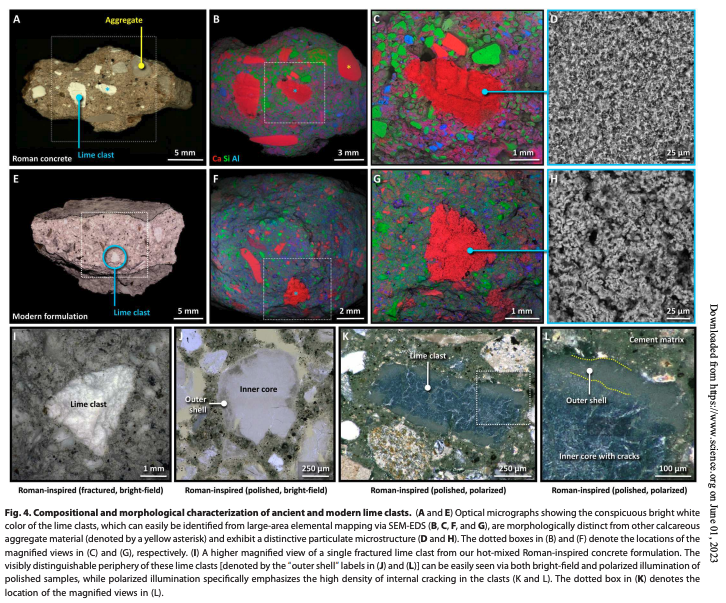

Masic and his team began to question the presence of lime clumps found in the concrete. It had been documented that samples from across the Roman empire had these so-called “lime clasts” but most researchers assumed the clumps of lime were due to poor mixing.

To Masic and his team, this was an odd attribution. Roman engineers were methodical, they detailed instructions stating volcanic ash and the purest form of bright white lime must be utilized when mixing concrete. So why would most samples of Roman concrete all contain lime clasts that weren’t fully mixed? Were all the workers in the Roman empire failing to thoroughly mix their concrete resulting in lime clasts being distributed throughout? What a coincidence it would be if workers across the entire Roman empire were all making the same mistake.

Lime Clasts: The Key to the Secret Recipe

The answer to these questions was the key to unlocking the mystery and revealing the secret recipe to Roman concrete.

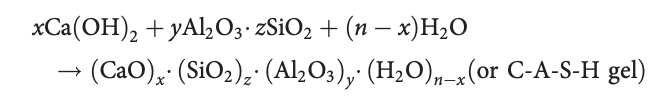

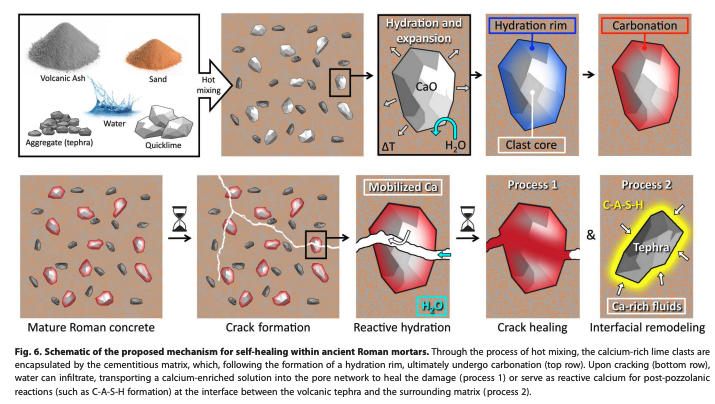

To form concrete, ancient Romans began by calcining lime from a stone containing calcite (CaCO3), typically limestone. This process allowed them to form quicklime or calcium oxide (CaO). When quicklime and water were mixed (a process often referred to as hot mixing) it created an exothermic reaction. The heat produced during this reaction prevented the lime from fully dissolving. The mixture was then incorporated with volcanic ash, ceramic fragments, pozzolana, sand, and water to form a hydraulic concrete.

The process of hot mixing or slaking resulted in pockets of quicklime failing to dissolve and remaining lime clasts formed throughout the mixture. Hot mixing gets its name from the extreme temperatures that result from the mixing of water and quicklime, a dangerous process that can lead to explosions. But Masic and his team hypothesized lime clasts were responsible for the self-healing properties of Roman concrete, so they decided to take the risk and recreate the recipe.

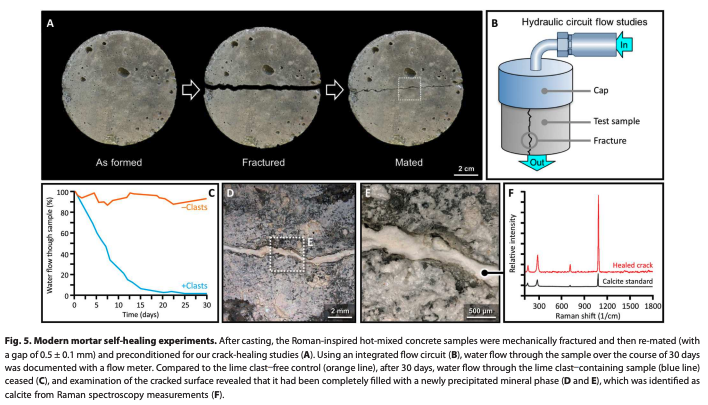

When the team duplicated the process of hot mixing in the lab, no explosions occurred. They were able to create a material with lime clasts distributed throughout. After deliberately breaking the concrete to create fissures, water was fed through the material. As the water reached the lime clasts, the lime dissolved and recrystallized, filling the cracks and strengthening the material. The concrete the team produced without hot-mixed cement, never healed.

Potential Impact of Discovery

The discovery Masic’s team made in January 2023 after years of research is huge. Modern concrete can’t heal cracks larger than 0.3 millimeters wide. The Roman concrete Masic’s team created, is capable of healing cracks up to 0.6 mm wide.

The US alone produced 95 million tons of concrete in 2022 and global production accounts for 8% of the world’s carbon dioxide emissions. Concrete makes up the largest percentage of construction and demolition waste, representing a third of all landfill waste. With concrete structures requiring demolition and reconstruction roughly every 100 years, self-healing concrete could greatly reduce this waste in addition to the strength and integrity it would add to our infrastructure.

The short lifespan of concrete and the amount of carbon dioxide it produces alone contribute to the pollution of the planet in mass amounts. While concrete is the most commonly used building material, it isn’t as durable as it seems. Modern concrete only has a lifespan of 50-150 years, and after half a century requires extensive maintenance, repair, or replacement.

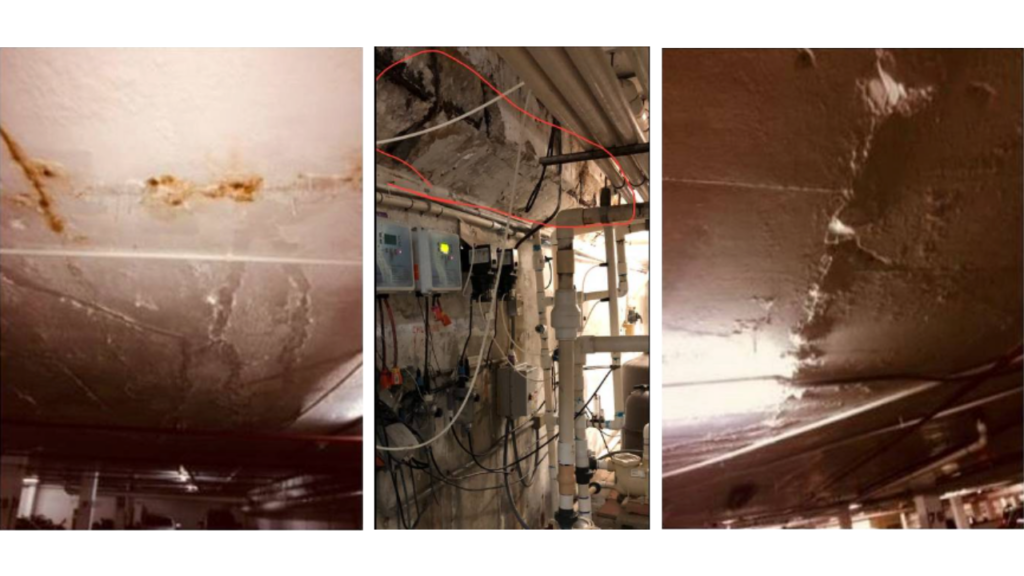

The rapid deterioration of concrete is a challenge for those tasked with maintenance and repair efforts. Modern concrete is often reinforced with steel rebar to improve tensile strength. Weather and stress leads to tiny cracks in concrete, which can expose the steel rebar to moisture. This causes the steel to corrode and rust, expanding the concrete and cracking the material even further.

Other signs of degradation include:

- Cracks in concrete foundation or supports

- Shifting of concrete in large expanse areas

- Cracking grout lines

- Peeling concrete

- Leaning structures

- Loose, chipped, damaged components

- Signs of flaking, rusting or other indications of deterioration

- Older age of concrete

To fix these issues, extensive maintenance, repair, or replacement is necessary. Regular maintenance practices should include:

- Visual Inspection of material

- Frequent inspections of critical problem areas (joints, support joints, large expanses)

- Corrosion evaluation and regular moisture testing, pay close attention to areas that are at risk for water intrusion

- Chloride analysis to avoid corrosion of steel

- Chemical testing to ensure no oxidation

- Petrographic analysis

- Scanning electron microscopy

- Other condition monitoring practices

- Cable break detection to monitor tension support and durability

- Regular communication of maintenance teams to note issues and concerns

Consequences of Poor Maintenance

The consequences of poorly maintained concrete structures can be devastating. Unfortunately, a prime example of this is the Surfside Condominium Collapse.

On June 24, 2021, the Champlain Towers South, a 12-story building collapsed killing 98 individuals and injuring several others. The collapse was largely attributed to the degradation of reinforced concrete structural supports.

Just days before the collapse, a contractor photographed visible damage which included cracking concrete and corroded rebar. The contractor noted there were large amounts of standing water in the parking garage under the building and in 2018 an inspection report flagged a major problem with the drainage system that allowed standing water to pool, causing extensive damage to the structural concrete slabs below.

Room for Improvement

There are many downfalls to the use of concrete in construction, but new innovations and discoveries are providing solutions to these problems.

Other alternatives can be used for steel reinforcement, such as stainless steel, aluminum bronze, and fiber-polymer composites, however these materials are not widely used as they come with a higher price tag. Planners and developers typically opt for steel rebar, without considering the extensive maintenance, repair, and replacement costs associated with this material.

New technologies can address steel corrosion such as cathodic protection, and electrical or acoustic monitoring. Concrete can also be treated with rust-inhibiting compounds, but these chemicals can be toxic and are not always suited for buildings. None of these activities solve the problem of steel corrosion and the inherent degradation of concrete surrounding the rebar, but slightly prolong the materials lifespan.

Admir Masic is very cognizant of the multitude of benefits a self-healing building material contains. Following his discovery, a start-up, DMAT, was launched in the US. The start-up’s main product is D-lime, a self-healing concrete that lasts 50% longer than traditional concrete by self-healing small cracks to prevent deterioration. The key ingredient is of course: lime.

Masic believes self-healing concrete would be best suited for structures built in or near water, such as dams and seawalls but could eventually spread to the construction of buildings, bridges, and tunnels.

The re-discovery of the recipe to create self-healing concrete has the power to change the way the modern world constructs, maintains, and repairs infrastructure. Reversing the effects of water on concrete by utilizing it as a tool to strengthen the material would help modern buildings extend their life, lower maintenance costs, and most importantly, keep people safer.

Natalie Johnson

Natalie Johnson is the previous editor/website administrator for MaintenanceWorld.com, and is currently a student at Campbell University Norman Adrian Wiggins School of Law.

Related Articles

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

South Carolina Ranked as the #1 State for Manufacturing

The Decade of American Reshoring

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

HBD Condition Monitoring Devices at the center of Ohio Derailment

Failure Analysis Uncovers the Cause of the Keystone Oil Spill