Preventing Failures and Extending Life

Torbjörn Idhammar, CEO & President IDCON INC

IDCON’s “Current Best Practices” include nearly 300 elements. We normally use this document to assess plant reliability performance. I’ve picked a few best practices from this document for this articles series. After reading a few of our best practices I ask you to check your own plant in order to rate the performance.

The equipment life cycle starts with specification, design and engineering of equipment and production systems. This leads us to an important issue, life-cycle cost.

Check 1: Life-cycle cost (LCC)

Specify, design and buy assets based on LCC instead of just the cost of purchasing equipment. LCC means that the total cost to buy and own an asset is considered, not just the purchase price.

Design for reliability: Pump inlet should have 10 times the diameter of straight pipe to avoid turbulence and cavitation.

Operations, maintenance and engineering must work in a close partnership in the early stages of a new installation project in order to establish a good LCC process. Typical good results are equipment designs that are easy to maintain and are reliable, and equipment that easily can be monitored for condition.

For example, in a plant with a reasonably good LCC process, there would be 10 times the diameter of straight pipe to the inlet of single-sided centrifugal pumps in order to avoid turbulence and cavitation.

Tank entry ports would have hinges for quick and safe entry instead of a traditional tank entry that requires lifting devices and two people to open it. The design also would have as few bolts as possible to reduce wrench time.

Other examples would be installation of oil sampling ports on all pertinent oil reservoirs. Gauges would have operating ranges marked in order to quickly check the current reading. Jacking bolts (push bolts) would be installed on motors and gearboxes for accurate alignment.

Most plants have hundreds of examples where it’s obvious engineers haven’t worked closely with maintenance and operations. The problem’s root is often that engineers are recognized by management for completing projects on time and under budget. Therefore, engineers have no incentives to consider LCC.

Check 2: Alignment

Most plants have the basic requirement for good alignment. They have tools and training. The question is, can we assume alignment is done well because the basics are in place?

Many plants I visit have an issue with getting the time to do a good alignment job, and/or don’t have the correct design, and/or don’t maintain bases and foundations to enable good alignments. In some cases, standards (such as heat checking and avoidance of pipe strain) aren’t followed.

Walk around your plant and estimate your alignment by checking for: poor foundations, equipment without jacking bolts, motors with beat marks from sledgehammers, shim packs larger than four, bolt-bound equipment/undercut bolts and hot bearings. All of these are possible signs of poor alignment.

Design for maintainability: The tank entry port to the left has many bolts and no hinge. The wrench time is cut drastically by adding a hinge and allowing fewer bolts in the design (bottom)

This article series discusses sample business processes that must be implemented in order to improve overall plant reliability. This article and the previous one focus on preventing failures and extending equipment life. The series will continue in upcoming issues with topics such as spare parts management, condition monitoring, planning and scheduling, and root cause problem elimination.

If you ask any maintenance department how failures can best be prevented, the No. 1 answer is usually that the operations department needs to stop wrecking equipment. If you ask operations how reliability can be improved, the top answer is almost always for maintenance people to work instead of sitting idle.

We know that maintenance people are idle because effective work processes such as planning, scheduling and spare parts management aren’t defined and/or well-instituted. But in this article, I’d like to discuss operating practices with regard to reliability.

Operating practices are a vital part of any preventive maintenance process. Good practices prevent failures. Poor practices encourage failures.

A plant worker changes the pressure setting on a cylinder.

The cylinder dead-heads and shakes loose or gets damaged due to the wrong pressure setting.

Some good questions for the management team are: “Do we have well-documented and communicated expectations in our standard operating practices (SOPs)?” “Do the SOPs cover equipment reliability issues?” “Does maintenance provide adequate input into how equipment should be operated to avoid problems?” “Are operators trained in SOPs?” “Does operations management have the skills to understand reliability issues in an operating context?”

It’s common to see SOPs in plants, but do they include equipment reliability issues? A few examples follow.

Pneumatic cylinder: At one plant that I worked in, it was common to see operators increase the pressure setting on the pneumatic cylinder as much as 100 percent in order to get the equipment to run faster. When the cylinder exceeded twice its designed speed, it “dead-headed” and usually shook loose or bent the rod. As a result, maintenance changed the pressure setting during the area’s weekly PM. In talking to the operators, they can’t remember ever being told not to change the pressure setting. Air pressure settings weren’t part of the operator training. SOPs for the equipment didn’t exist.

Motor start-up: When you push the start button of an AC motor, the current surge through the motor is usually four to seven times the 100 percent load. If the start button is pushed several times in a short time interval, it’s common to damage or burn the motor windings. Do your operators know this fact and operate equipment accordingly?

Steam systems: An operating procedure as simple as opening a valve too fast can have devastating consequences for a piping system. The phenomenon is called water hammer. Here, steam enters a cold piping system and condenses into water. The water travels with great speed and causes damage to pipes and flanges as it travels through the system. Piping elbows are especially vulnerable. This is a common problem in many industries.

Open communication between operations, maintenance and engineering is needed during the design and selection phase of equipment. That communication must continue after installation.

I’ve seen great results by having operations and maintenance do inspections routes and PM tasks together at least once a week. They should also jointly report findings to supervision.

Related Articles

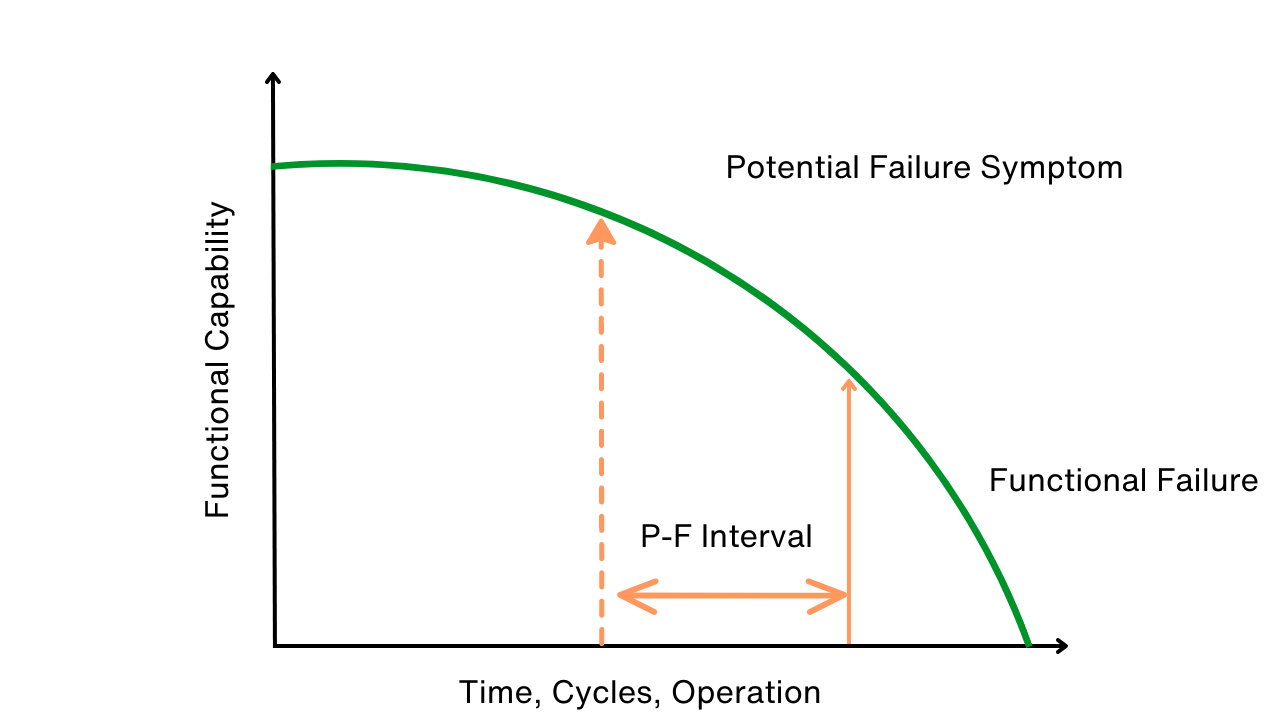

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?

Design for Maintainability