Coal Plant O & M: Condition Monitoring Cuts Mirant Mid-Atlantic’s Costs

Douglas J. Smith, IEng, Contributing Editor

Condition monitoring (CM) has become an increasingly important aspect of power plant maintenance philosophy. Today many utilities are using a variety of predictive maintenance (PM) techniques like CM to lower their operation and maintenance expenses.

Over the years, gencos have developed a diverse collection of CM programs of various breadth, depth, and formality. All are based on the proven benefits of using CM and PM: lower O&M costs and higher unit availability.

Unfortunately, after a merger or a corporate mandate to cut costs, some utilities question the value of implementing or continuing to implement CM and PM systems. What they should be questioning is whether they can afford to do without them.

Monitoring the condition of plant equipment provides enormous opportunity to positively influence daily and long-term maintenance activities. CM is a very important part of any comprehensive PM program. In the long run, CM almost always provides enough benefits to justify its expense.

Mirant Mid-Atlantic’s Program

According to Joe Humphrey of Mirant Mid-Atlantic, adopting CM is just common sense. Quantifying its benefits is usually enough to justify the practice, he says.

Mirant Mid-Atlantic’s power plants (formerly owned and operated by Pepco) employ a multifaceted approach to maintenance. Like many gencos, Mirant recognized the value of PM back in the 1960s and 1970s. During that era, the company developed a program that relied on doing large numbers of maintenance inspections at specific time intervals. It replaced a “breakdown maintenance” philosophy (run equipment until it fails) that had been implemented for years, at rising costs.

Eventually, Mirant and the power industry as a whole concluded that PM was indeed a more cost-effective approach because it allowed for better planning and scheduling of equipment. Mirant’s first real PM program began in 1976 with the hiring of a vibration monitoring and analysis team. Humphrey emphasizes that the implementation and continued development of the program would not have been possible without the full support of the utility’s upper management.

Nonetheless, it took many years to convince maintenance personnel that monitoring and analyzing a machine’s vibration could provide valuable information about its overall condition. Ultimately, they accepted the technology. As the program progressed, infrared thermography, ultrasound, oil analysis, and other techniques were added to the company’s arsenal of monitoring and diagnostic tools (see sidebar, previous page).

Bottom-Line Benefits

Unlike other utilities, Mirant Mid-Atlantic no longer requires the maintenance staffs of its plants to quantify the projected benefits of a CM system before buying and installing it. However, early in Mirant’s project, each fault (identified by routine monitoring) was recorded. The projected costs of repairs were then compared to the costs of repairs without having a CM system in place. To make the comparison valid, the utility used information from veteran O&M personnel with little or no prior experience using CM technology.

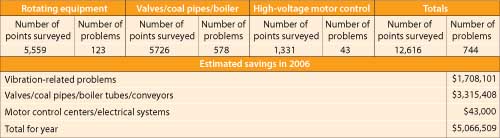

All of the data collected became the basis of the cost/benefit analysis of estimated future cost savings. Mirant recorded individual data points on a regular basis until 1998, when it decided to simplify the analysis by using an average figure per problem identified. Based on 1998 figures for each vibration-related fault, the utility saved $13,887 per incident. The total included savings of $5,736 for valves and coal piping, and $1,000 for each motor control center (MCC)/electrical problem detected.

According to Humphrey, using averages is sufficient to produce ballpark estimates of the benefits achieved by deploying the CM system. On occasion, Mirant engineers perform a detailed analysis of the cause of a significant fault. Humphrey says that these analyses almost always confirm that averaging yields conservative estimates of benefits. The table shows the estimated savings produced by Mirant Mid-Atlantic’s system in 2006, delineated by equipment type.

Summary of equipment monitored and estimated savings in 2006. Source: Mirant Mid-Atlantic

Proving Its Worth

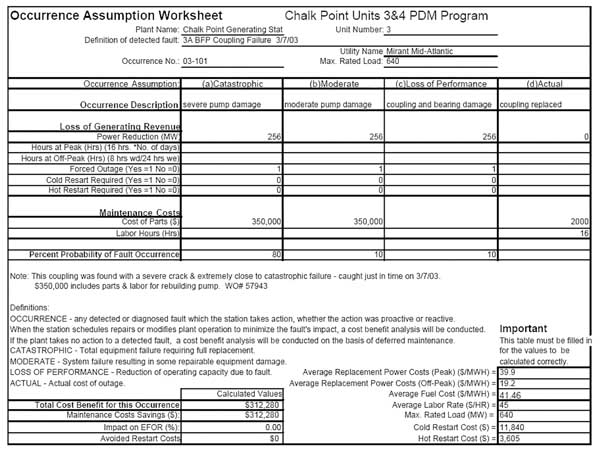

Here’s an example of how the CM program works in practice. In March 2003, a routine vibration survey detected a step increase in vibration on the inboard bearing of a turbine-driven boiler feedpump. Noting the reading, operators immediately reduced the pump’s speed and took the unit out of service later that day. A subsequent analysis (see figure) indicated the probability of a coupling problem.

The cost/benefit analysis worksheet for a boiler feedpump. Courtesy: Mirant Mid-Atlantic

When maintenance staffers inspected the coupling, they found that it was no longer lubricated and had a significant crack. If the vibration had gone undetected, a very expensive catastrophic failure would likely have occurred. Mirant estimated that repairing the collateral damage to the pump, and buying power to replace the lost production from the affected unit while it was out of service for an extended period, would have cost more than $300,000. After replacing the coupling, the pump was returned to service, and vibration returned to acceptable levels.

Mirant Mid-Atlantic’s Condition-Monitoring Program

Mirant Mid-Atlantic’s condition-monitoring team consists of a central group of four technicians and one team leader. The team’s primary responsibilities are the company’s four coal-fired power plants; as resources and priorities permit, the team also provides support to other assets.

The predictive maintenance (PM) technologies currently used by the program include:

- Vibration monitoring and analysis — of virtually all rotating equipment, including motors, pumps, fans, compressors, turbines, and generators.

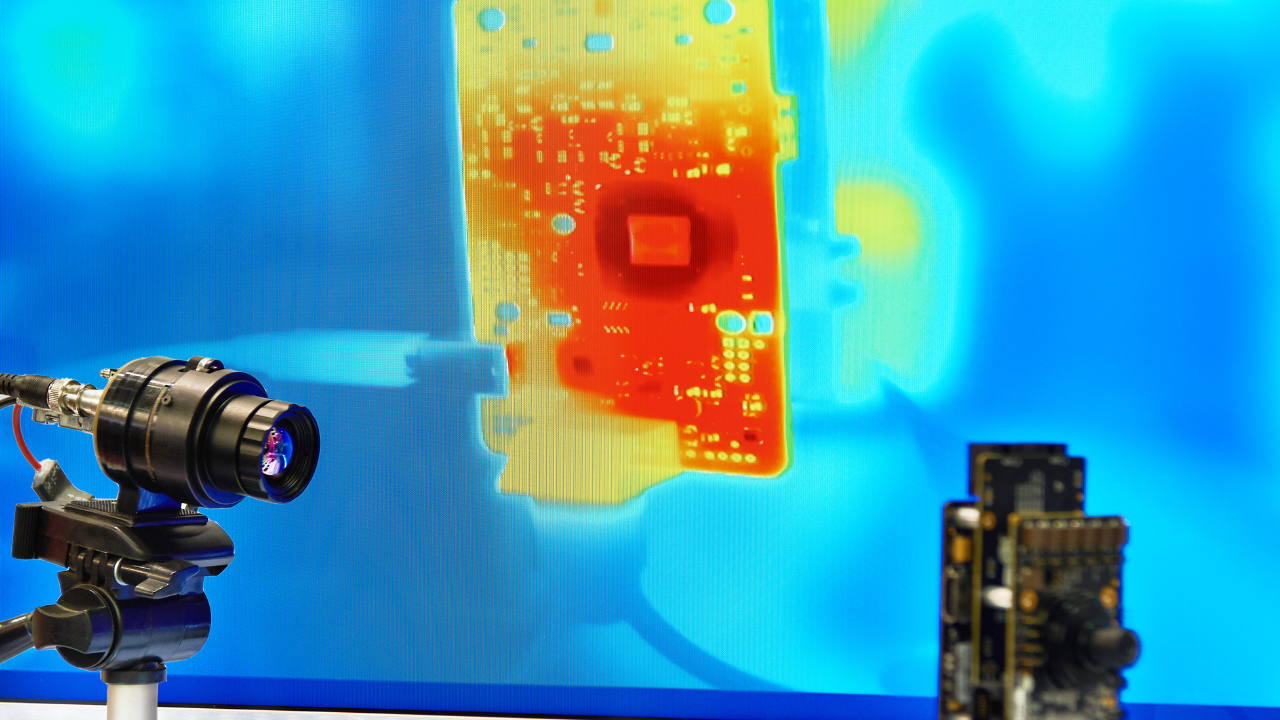

- Infrared (IR) thermography — surveys of valves, motor control centers, load centers, transformers, boiler casings, boiler tubes, coal conveyors, and motors.

- Ultrasonic leak detection — performed routinely on valves (in conjunction with IR thermography) and on tanks and piping when requested by plant personnel. Ultrasound is also used to detect seal rubs, loose parts, and cavitation in rotating equipment, and to identify faulty valves in reciprocating compressors and arcing and corona in high-voltage switchgear.

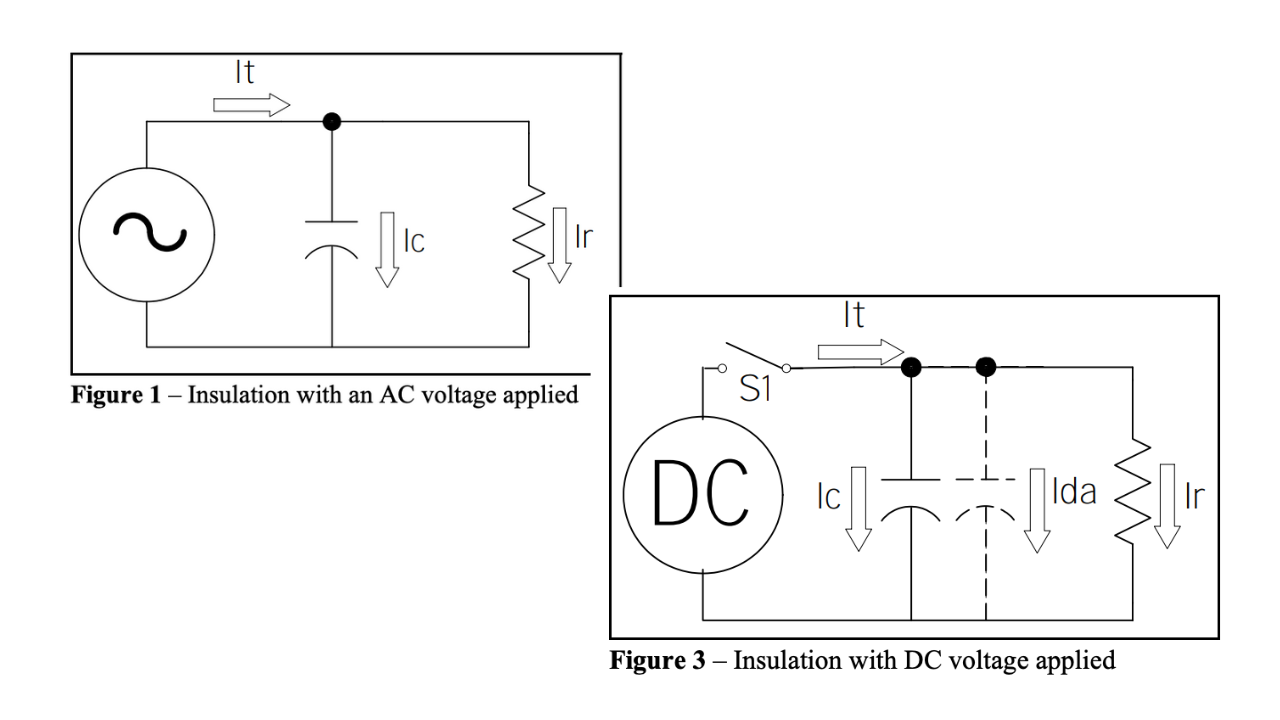

- Motor current signature analysis — used to identify broken rotor bars on motors susceptible to this type of failure (typically, high-voltage motors that are started frequently).

- Motor circuit evaluation — used to determine when motors rated at 2 kV or higher should be overhauled.

- Partial discharge testing — used to measure and trend the condition of generator windings.

- Slow-speed dynamic balancing — of machine rotors weighing between 50 pounds and 200,000 pounds prior to reassembly. Although it is not specifically a PM technology, balancing can be considered a vibration-monitoring activity.

- In-place dynamic balancing — of rotating machines such as motors, fans, exhausters, steam and combustion turbines, and generators.

- Oil analysis — a PM tool that has proven effective at Mirant Mid-Atlantic generating stations.

This article is based on a paper presented by Joe Humphrey of Mirant Mid-Atlantic at the ELECTRIC POWER 2007 Conference & Exhibition.

Related Articles

Principles of Insulation Testing

Top Tips for Selecting Pressure Measurement Transmitters

Gearbox Diagnostics Fault Detection

What is Vibration?

Why Record? Infrared Video

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera