What are the Differences between CMMS, EAM, and APM?

Reena Sommer, Ph.D, Content Writer and Trial Consultant

Posted on 8/15/2023

Introduction

Making the decision to shift maintenance operations from manual methods to software is a huge step. The process can also be overwhelming and confusing for many professionals especially if you have had little to no experience with maintenance and asset management software in the past. To begin, selecting a system that best fits your organization’s needs is crucial because it involves a substantial investment of time, resources and money. In addition, the available software platforms have become more sophisticated and robust in recent years. Maintenance management software continues to evolve as developments in new technology emerge as well as in response to market and economic demands.

Today’s systems offer a wide range of capabilities designed to meet the needs of organizations of all types and sizes, and across all business and industry sectors. It’s no wonder that selecting a system that is best suited to your business can be confusing. The purpose of this article is to highlight the key differences between various platforms, specifically computerized maintenance management software (CMMS), enterprise asset management (EAM) software and asset performance management (APM) software. With the end goal of leaving you the reader with a better understanding of the benefits these platforms provide and in a better position to start researching solutions for your organization.

What are CMMS, EAM and APM?

Before getting into the differences in these systems, let’s begin by looking at how they overlap in functionality.

Asset Management

All three systems have the capability of managing assets, though the scope and focus do differ.

Data and Information Management

CMMS, EAM, and APM are designed to collect and store data related to assets, maintenance activities, and performance. They all provide a centralized repository for information, making it possible for users to access historical records, track asset performance, and analyze maintenance trends.

Preventive Maintenance

Each system incorporates preventive maintenance to varying degrees.

Work Order Management

CMMS, EAM, and APM systems generally include work order management functionalities. This allows users to create, assign, and track work orders for maintenance tasks, repairs, and inspections.

Reporting and Analytics

CMMS, EAM, and APM offer reporting and analytics capabilities to help users make data-driven decisions. These systems can generate various reports on asset performance, maintenance costs, downtime, and more.

Integration

While they are separate systems, CMMS, EAM, and APM can often integrate with other enterprise software like ERP (Enterprise Resource Planning) systems, IoT (Internet of Things) devices, or other business applications. The systems’ ability to “talk” to each other makes smoother data exchange possible and because of this, CMMS integration enhances overall asset management processes.

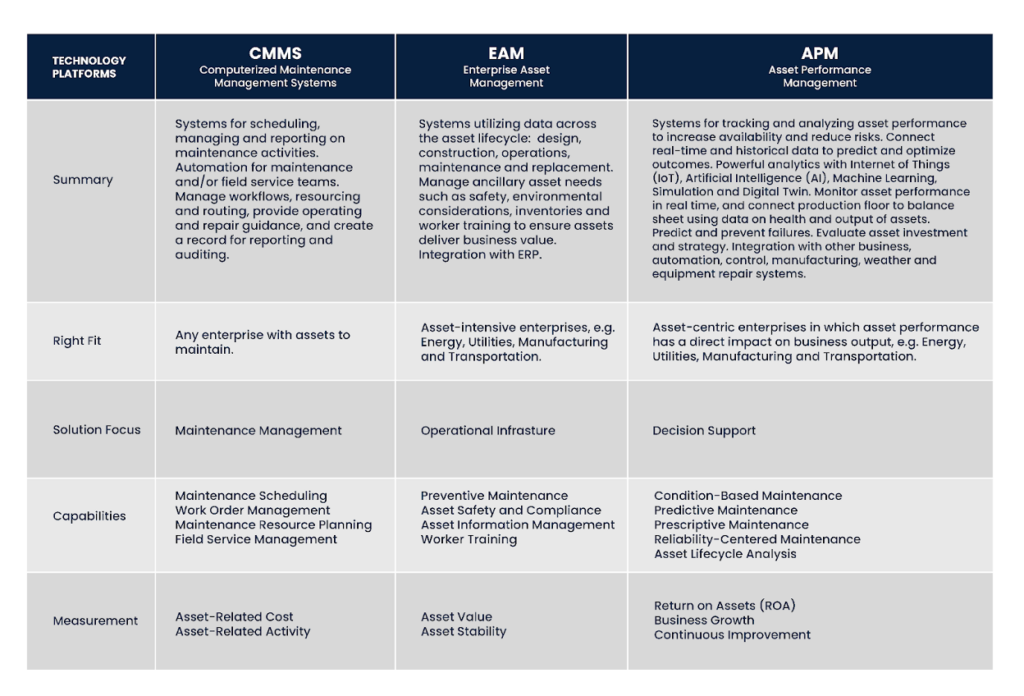

Differences between CMMS, EAM and APM

Now that we’ve identified the major similarities between CMMS, EAM and APM, let’s look at the distinct differences between them. You will find that the differences noted will offer you one way to identify the system that is best suited for your organization.

CMMS (Computerized Maintenance Management System):

CMMS is a software application that is uniquely designed to help organizations efficiently manage their maintenance operations. It focuses on organizing and scheduling maintenance tasks, tracking work orders, managing assets, and monitoring equipment maintenance histories. Key CMMS software features include preventive maintenance scheduling, inventory management, work order tracking, and generating maintenance reports. CMMS is primarily used by maintenance teams to streamline their day-to-day tasks and ensure that equipment is well-maintained. Its main focus is on the maintenance and repair of assets.

EAM (Enterprise Asset Management):

Compared to CMMS, Enterprise Asset Management is a broader system in which its scope encompasses all aspects of managing an organization’s assets throughout their lifecycle. It includes maintenance management capabilities, but it goes beyond just ongoing maintenance operations. Specifically, the system manages acquisition, installation, maintenance, and disposal of all assets. EAM also involves strategic planning, procurement, risk management, and asset performance optimization. EAM solutions are more comprehensive and often cater to larger organizations or industries that deal with complex and diverse asset types. EAM systems provide a holistic view of assets, allowing organizations to optimize asset utilization, minimize downtime, and make data-driven decisions about asset investments and replacements.

APM (Asset Performance Management)

Asset Performance Management takes EAM a step further. It is considered a specialized subset of EAM that focuses on optimizing the performance and reliability of critical assets. Like EAM, APM oversees the entire lifecycle of assets but with an emphasis on optimizing their performance and reliability. It utilizes data analytics, predictive maintenance, and condition monitoring to assess the health of assets, predict potential failures, and plan maintenance activities more proactively. APM solutions are particularly valuable for industries with high-value assets, such as manufacturing plants, power generation facilities, and transportation sectors. By implementing APM, organizations can reduce unplanned downtime, extend asset life cycles, and improve overall operational efficiency.

Organizations that are Best Suited for CMMS, EAM and APM

Having looked at the similarities and differences between CMMS, EAM and APM, let’s dig a bit deeper by looking at the types of organizations that are most likely to use them.

CMMS (Computerized Maintenance Management System)

Recall that the focus of CMMS is on streamlining and managing maintenance activities, work orders, and equipment-related information. Companies that heavily rely on physical assets and machinery tend to choose CMMS. Industries that often use CMMS include:

- Manufacturing: Manufacturers use CMMS to maintain and manage production equipment, minimize downtime, and ensure smooth operations.

- Facilities Management: These are companies that are responsible for maintaining large buildings, offices, or campuses. They utilize CMMS to schedule and track maintenance tasks on HVAC systems, lighting, plumbing, etc.

- Healthcare: Hospitals and medical facilities choose CMMS to manage the maintenance of critical medical equipment and facilities.

- Transportation: Companies in the transportation sector such as airlines, railways, shipping opt for CMMS to maintain their vehicles and infrastructure.

EAM (Enterprise Asset Management)

Noted previously, EAM goes beyond the scope of CMMS by providing a comprehensive approach to managing an organization’s assets throughout their lifecycle. Because of these factors, companies that heavily depend on large, complex, and costly assets often choose EAM. Industries that benefit from EAM include:

- Energy and Utilities: These include facilities such as power plants, water treatment facilities, and utility companies. EAM has the ability to manage their vast infrastructure and equipment.

- Oil and Gas: Companies in the oil and gas sector use EAM to manage their drilling rigs, pipelines, and refineries.

- Transportation and Logistics: Companies with fleets of vehicles or aircraft utilize EAM to optimize asset utilization and track maintenance activities.

- Public Sector: Government agencies and municipalities use EAM to manage public infrastructure, such as roads, bridges, and public buildings.

APM (Asset Performance Management)

APM, which is a specialized subset of EAM that focuses on using data analytics and predictive maintenance techniques. These techniques are geared toward optimizing asset performance and maximizing uptime. This system is particularly beneficial for companies looking to move from reactive maintenance to proactive maintenance strategies. Industries that commonly select APM include:

- Manufacturing: Manufacturers choose to use APM to predict equipment failures, improve overall equipment effectiveness (OEE), and optimize maintenance schedules.

- Energy and Utilities: APM helps energy companies predict and prevent equipment failures in power generation and distribution systems.

- Aerospace and Defense: Companies in this sector utilize APM to enhance the performance and safety of aircraft and defense systems.

- Mining: APM assists mining companies in optimizing the performance of heavy machinery and reducing downtime.

Conclusion

CMMS (Computerized Maintenance Management System), EAM (Enterprise Asset Management), and APM (Asset Performance Management) are three different kinds of software solutions designed to help businesses manage and optimize their maintenance and asset-related activities. While they serve distinct purposes, there are both similarities and differences between them. In general, it’s important to recognize the unique purposes and features of each when selecting a system that best fits with the needs of your organization.

Keep in mind that CMMS software mainly focuses on maintenance management, EAM is broader and covers the entire asset lifecycle, and APM is centered on optimizing asset performance throughout their lifetimes. Each system is suited for different industries and organizational needs. Because of the differences in the systems’ purpose and functionality as well as a wide range of their capabilities, companies of different types and across various industries are able to benefit from implementing these systems.

To recap, CMMS is primarily concerned with day-to-day maintenance operations and work order management. EAM is a broader system that encompasses all aspects of asset management throughout their lifecycle. APM, on the other hand, is a specialized subset of EAM that focuses on optimizing the performance and reliability of critical assets through data-driven approaches. It’s also worth noting that some companies may opt to implement a combination of CMMS, EAM, and APM functionalities depending on their specific needs and the complexity of their assets and operations. In the end, the choice of a system or in a combination of systems depends on an organization’s specific needs, the scale and complexity of its asset management requirements, budget and internal resources. Being aware of the similarities and differences between the systems as well as industry preferences offers a guide to informed decision making.

Reena Sommer

Reena Sommer has written extensively about CMMS and maintenance management best practices since 2018. Reena has been a contributor for Hippo CMMS, Click Maint among others. She has her Ph.D. in Psychology from the University of Manitoba. Reena hails from Winnipeg, Canada and currently resides in Chicago, Illinois, USA.

Related Articles

Too Small for a CMMS? Think Again

The Role of Information Technology in Plant Reliability

The Future of CMMS