Motor Condition Monitor and its Applications in Foundry Industry

Motor Condition Monitor has many successful applications in different areas of industry. In this section, three applications of MCM in foundry industry will be presented.

[webinar] Embracing Digital Transformation in Maintenance & Plant Operations | March 13 at 10AM EST – Register Now

Motor Condition Monitor has many successful applications in different areas of industry. In this section, three applications of MCM in foundry industry will be presented.

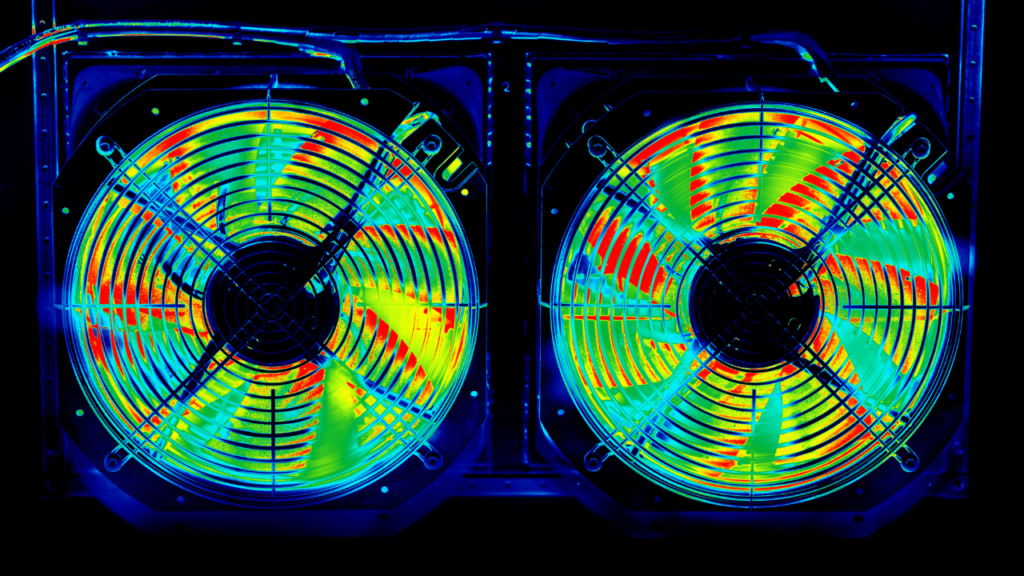

Infrared Thermal Imaging is an excellent condition monitoring tool to assist in the reduction of maintenance costs on mechanical equipment. The technique allows for the monitoring of temperatures and thermal patterns while the equipment is online and running under full load. Most mechanical equipment has allowable operating temperature limits that can be used as guidelines. Unlike many other test methods, Infrared Thermal Imaging can be used on a wide variety of equipment including pumps, motors, bearings, pulleys, fans, drives, conveyors etc.

There are many uses for infrared thermography other than inspecting electrical switchgear and mechanical components. Inspecting buildings for heat loss was one of the first commercial uses for infrared thermography.

As with many condition monitoring techniques, infrared thermography is a skilled art form that requires technician and engineeers to be educated in infrared physics, have a thorough understanding of applications and be able to develop their knowledge with continual field experience.

Mirant Mid-Atlantic’s condition-monitoring team consists of a central group of four technicians and one team leader. The team’s primary responsibilities are the company’s four coal-fired power plants; as resources and priorities permit, the team also provides support to other assets.

The first instruments for Condition Monitoring at Norske Skogn were purchased in 1971. Today we are using instrumentation of the 8th generation. We can see that each generation has given us an opportunity to improve the reliability of the CM program.

For Condition Monitoring (CM) purposes a range of technologies are available, each having its own strengths and weaknesses, and it is usual to consider each of them as a tool in the CM toolkit. The Acoustic Emission (AE) technique has a 40 year history of use for machinery condition monitoring and although it got off to a slow start, in recent years it has gained very widespread acceptance across industry.

Many power generation steam turbine generators today are required in service well beyond their intended lifetimes. Dismantling for inspection is expensive, and owners need to consider all relevant information in making the decision. Application of condition monitoring in all the applicable methods is justified, with each showing different degradation modes. Performance analysis is less well publicised, yet unlike vibration analysis and oil debris analysis, it will show conditions which reduce machine efficiency and output, such as deposits on blades and erosion of internal clearances. The paper outlines, with examples, some condition monitoring techniques that have contributed to retaining some large fossil machines in service for up to 17 years without opening high-pressure sections.

A common approach to looking at vibration spectra is to display the graphs and then ask “What is wrong with this machine?” Another common approach to analyzing vibration spectra is to display the graphs and then ask “What is this peak?” and “what is that peak” A better approach to analyzing data is to first ask “What faults can this machine have?”, “Which of these are most common for this machine?” and finally…

Click here to join the Maintenance and Reliability Information Exchange, where readers and authors share articles, opinions, and more.

"*" indicates required fields

delivered straight to your inbox

"*" indicates required fields