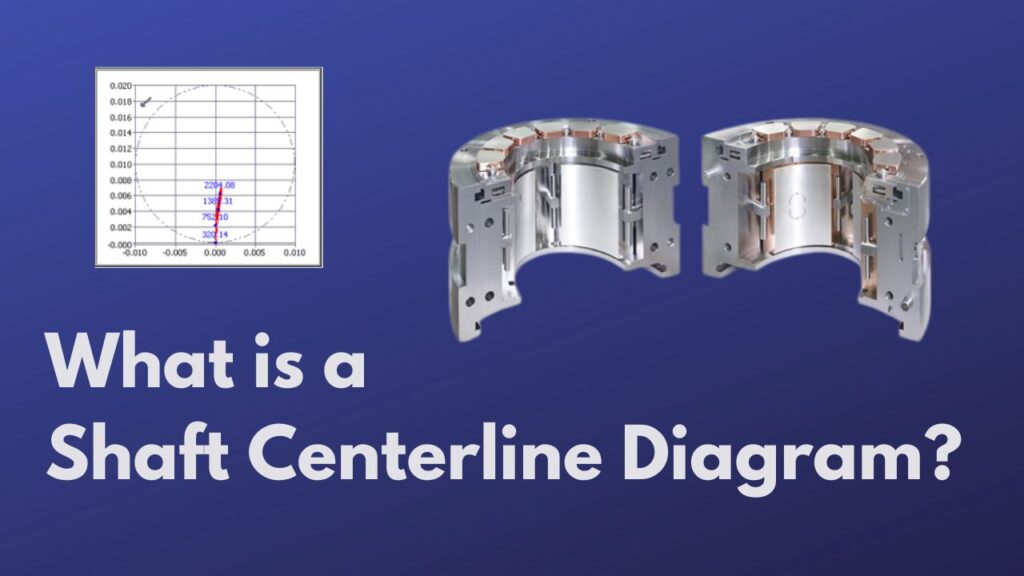

What is a Shaft Centerline Diagram?

A shaft centerline diagram is a plot used in the vibration analysis of journal bearings. It is also called a shaft average centerline diagram. The purpose of this graph is to display the average position of the rotor in the bearing. In short, for different bearing types, there is an expected or “normal” position of the shaft in the bearing. If this position changes, it can indicate a problem.