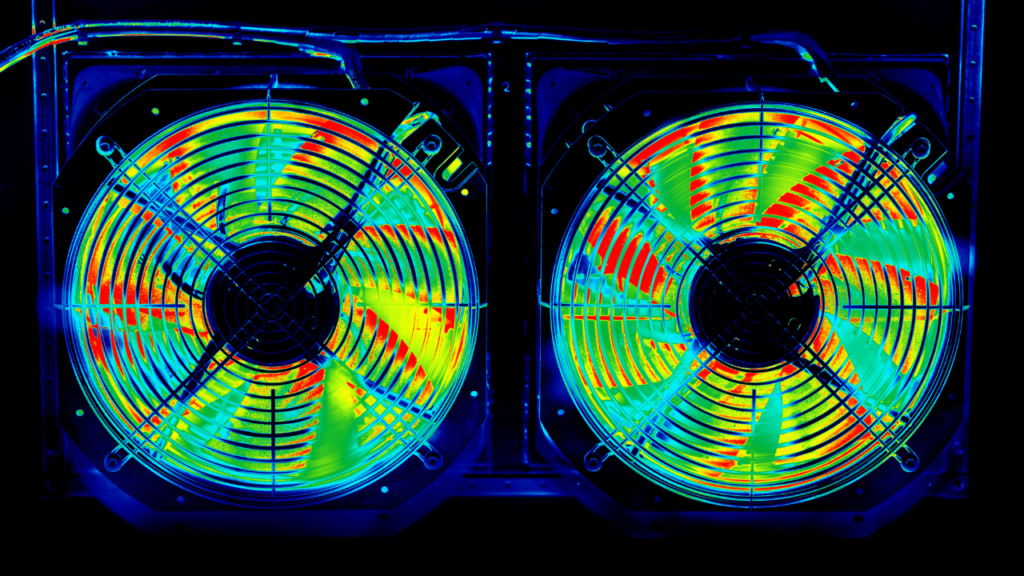

Visual Inspection: A Necessary Component of Infrared Inspections

It may seem that visual inspection goes beyond what thermographers are hired to do, but conscientious thermographers include notes and even images in their reports when they see code violations, broken equipment, incorrectly sized fuses, bad wiring, etc. A good thermographer will not ignore copper tubing used as a fuse, even if it looks fine in the infrared. Whether the inspection is insurance driven or a proactive stance, an infrared inspection and a visual inspection complement each other.