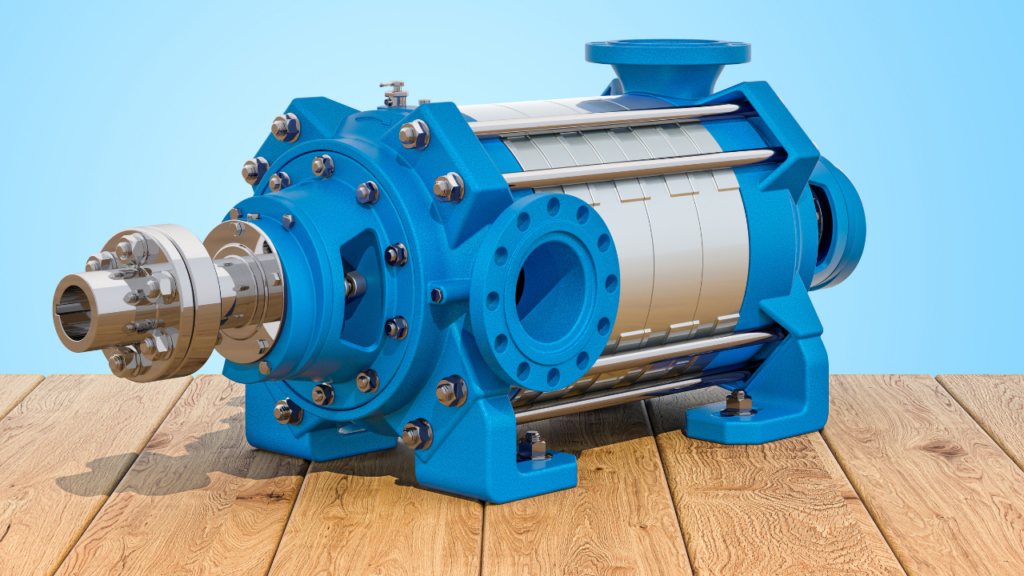

Pump Cavitation Solutions: Polymeric Solutions for Pumps Suffering from Cavitation

Pump cavitation is defined as the phenomenon of formation and consequent implosion of vapor bubbles in a region where the pressure of the liquid falls below its vapor pressure. Cavitation can occur in any fluid handling equipment, especially in pumps, one of the most important components of industry today. Technological advances in industrial protective coatings and repair composite materials have made it possible to repair pumps suffering from cavitation rather than simply replacing them.