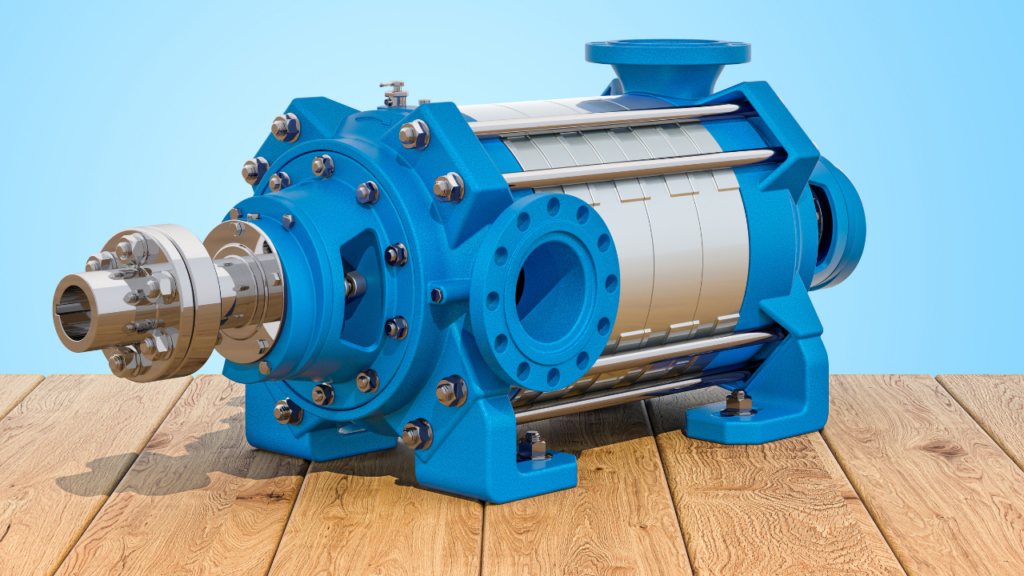

Maintenance Equipment: Basic of Centrifugal Pumps

The fact of the matter is that there are three types of problems mostly encountered with centrifugal pumps: design errors, poor operation, poor maintenance practices. The present article is being presented in 3 parts: covering all aspects of operation, maintenance, and troubleshooting of centrifugal pumps.