The Pump Affinity Laws 2-1

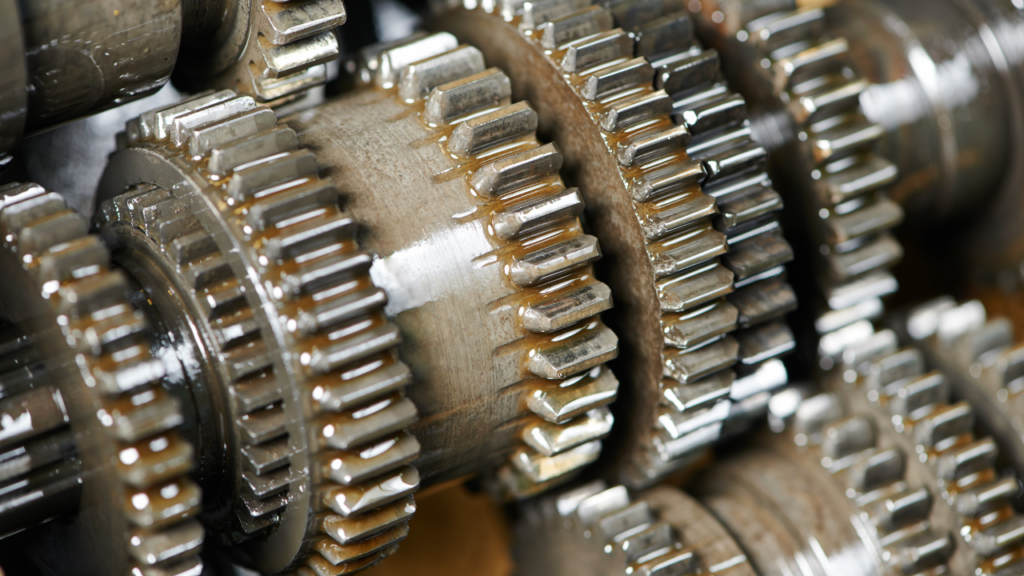

There are occasions when you might want to permanently change the amount of fluid you are pumping, or change the discharge head of a centrifugal pump. There are four ways you could do this, of the four methods the middle two are the only sensible ones. In the following paragraphs we will learn what happens when we change either the pump speed or impeller diameter and as you would guess other characteristics of the pump are going to change along with speed or diameter.