Keep Gearboxes Running: Gearbox Care and Maintenance

Keep Gearboxes Running: Gearbox Care and Maintenance Mike Sondalini, PWW EAM System Consultant with permission of BIN95 Business Industrial Network Posted 6/24/2025 A gearbox is used to control

[webinar] Embracing Digital Transformation in Maintenance & Plant Operations | March 13 at 10AM EST – Register Now

Keep Gearboxes Running: Gearbox Care and Maintenance Mike Sondalini, PWW EAM System Consultant with permission of BIN95 Business Industrial Network Posted 6/24/2025 A gearbox is used to control

Ensuring proper fit, tolerance, and equipment clearance is essential to the reliable operation and longevity of mechanical equipment.

Bearing isolators significantly reduce the life-cycle cost of rotating equipment by minimizing maintenance, downtime, and energy expenses while extending equipment life.

Rotary dryers, kilns, mills and reactors turn on tires and trunnions. Each tire is mounted to the rotating shell and revolves on two roller trunnions. If the alignment between the tire and trunnions is lost due to wear, poor repair, installation error or impact, the equipment will need to be tracked.

The semiconductor industry is a cornerstone of modern technology, enabling innovations that make the world smarter, healthier, greener, and better connected. Semiconductors, often referred to as the “brains” of electronic devices, are integral to everything from smartphones and computers to advanced medical equipment and electric vehicles, as well as less common household items like refrigerators, dishwashers, and our smart bulbs to connect devices to Alexa or Siri.

Large industrial facilities frequently have many closed cooling water systems. Plant personnel may, at times, overlook important issues related to water treatment and corrosion minimization within these networks; that is until a failure brings down a system and perhaps a unit operation, or worse. An important part of any preventive maintenance program is conscientious monitoring and control of cooling water chemistry.

Grease – use the right one for the job. The classification, selection, and application of greases is included in this article. Greases are designed for specific applications and if used in the wrong service they will not be effective. Compare the properties of greases and check those used in your equipment are suited to the service.

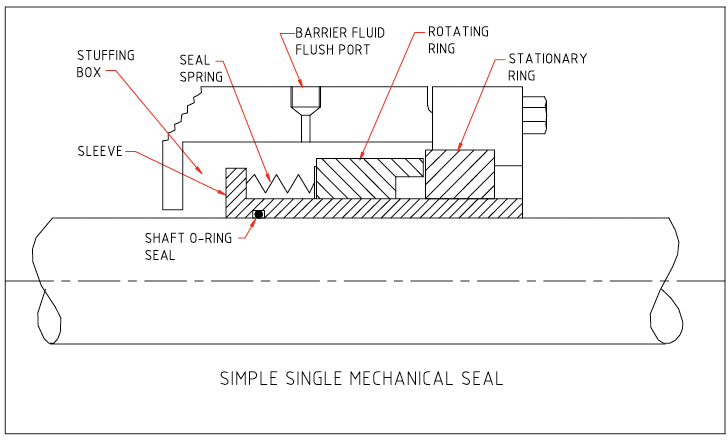

Get mechanical seals working properly. Mechanical seals are used to keep the bulk contents of rotating equipment such as pumps and compressors from escaping. They do this by sealing the shaft that protrudes from the casing. They require quality installation and operation conditions for a long life. Keywords: precision assembly, barrier fluid, stationary seal, rotary seal, alignment.

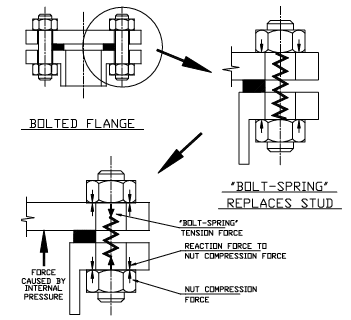

Prevent flange leaks with proper bolting practices. Bolts and gaskets behave like springs and unless flange bolts and nuts are properly tensioned the flange will leak. The correct tightening torque depends on bolt diameter, material of construction, process pressure and bolt fabrication.

Click here to join the Maintenance and Reliability Information Exchange, where readers and authors share articles, opinions, and more.

"*" indicates required fields

delivered straight to your inbox

"*" indicates required fields