Debunking the Myths Around Bearings

Installation, application, and lubrication myths. Learn these 11 ways to protect your assets from these harmful myths that circulate in the maintenance community.

Installation, application, and lubrication myths. Learn these 11 ways to protect your assets from these harmful myths that circulate in the maintenance community.

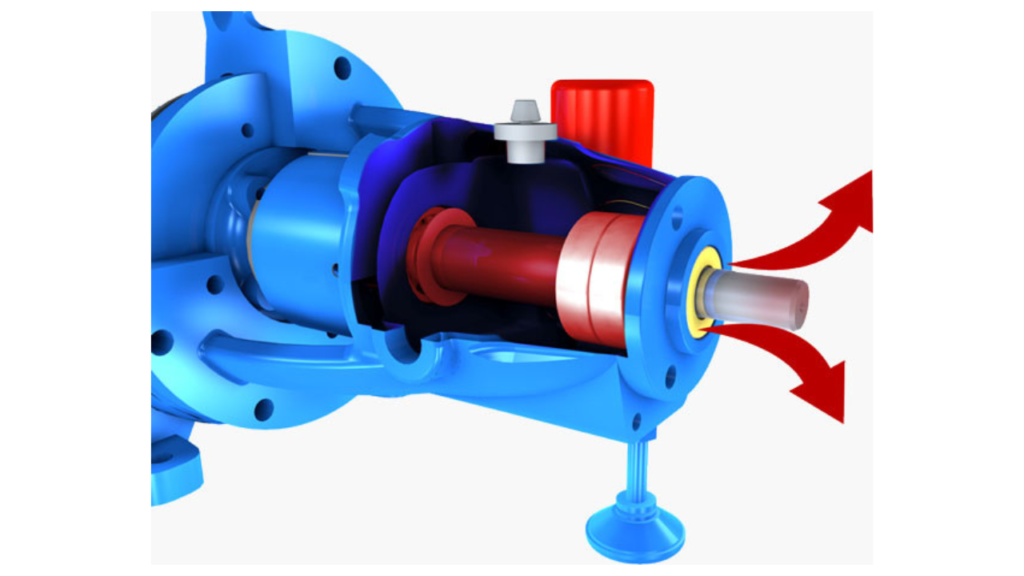

Several tests can be performed on a hydraulic pump to indicate its condition. The temperature of the pump case, the flow of the case drain and the current draw of the drive motor are common checks that can be done regularly and over a period of time to track the wear of a hydraulic pump.

Gear pumps are the most common type of positive displacement pump, ideal for transferring high viscosity fluids such as automotive oils, plastics, paint, adhesives, and soaps. As with any pump, proper operation and regular maintenance are vital to reducing costly pump repairs and maximizing pump efficiency. Below are helpful tips for operating your gear pump and ensuring it achieves a long operating life through regular maintenance. As with any pump, proper operation and regular maintenance are vital to reducing costly pump repairs and maximizing pump efficiency.

Pneumatic or electric? It’s not a new question. The merits of each have long been subject to discussion, but a fair amount of confusion continues to exist about which makes more sense for what. For example, are you considering replacing a compressor and 200 pneumatic cylinders with electric actuators because you think you’ll save on compressor costs? Or, perhaps you are thinking about building a new machine with pneumatics because 30 electric actuators are far too expensive. Make the wrong decision in either case and you could waste tens of thousands of dollars a year.

Experience shows seemingly identical rolling bearings operated under identical conditions may not last the same amount of time. In most cases, it is impractical to test a statistically significant number of bearings, so engineers rely on standardized bearing-life calculations to select and size bearings for a particular application. These calculations continue to evolve and become more accurate over time, reflecting the collective experience of the bearing industry, including recent advances in manufacturing, tribology, materials, end-user condition monitoring, and computation.

Research into bearing failures1 shows that just over half of them are a result of contamination of the bearing oil. Clearly, it is essential to ensure that this is minimized and, if possible, eliminated to achieve the optimum bearing life necessary to improve equipment reliability.

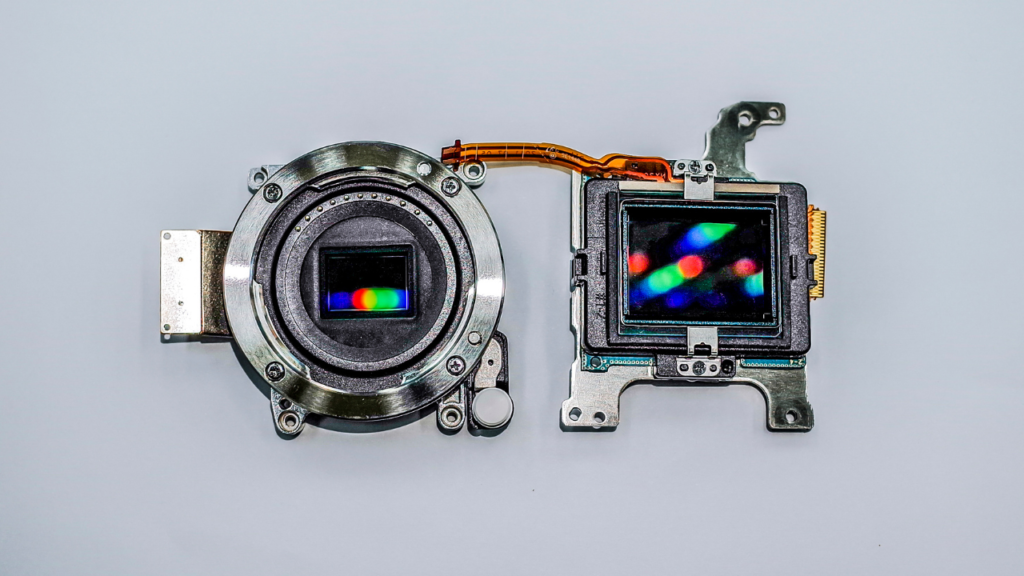

Spindles are one of the most expensive and sophisticated rotating components on the planet. They rotate at super high speeds with fits and tolerances 10 to 20 times what is required on other rotating devices, such as pumps or motors. If there ever were machines that needed to communicate their health and activity it would be spindles.

It turned out that the photoelectric sensor could only be adjusted to stay on all the time or off all the time when the cans were going by at any higher rate than Jog speed on the Seamer. We adjusted and adjusted the sensors. The sensors were replaced with new sensors. It did no good. The lines were stopped while we traced all the control and power wiring so we could try to determine if there was a problem in the wiring.

Process pump reliability logically involves a combination of fluid-related performance and design decisions that focus on engineering materials and the configuration of mechanical components. Recent case studies have pointed out improvement opportunities in the relative design conservatism found in certain process pump models. Combined with deficiencies in the training of personnel, it can be argued that pump reliability has not made as much progress as it perhaps could.

Do you want to get weekly tips & tricks?

Torbjorn Idhammar is the blog manager for MaintenanceWorld.com.

A maintenance and reliability management consultant, Torbjorn has spent 25+ years in the profession and provides advice to clients around the world.

Natalie Johnson is the site administrator for MaintenanceWorld.com.

She is responsible for reviewing submitted content for the site and ensuring that it provides value to the readers of the site.

Copyright © 2010-2024 Maintenance World. All rights reserved.

Click here to join the Maintenance and Reliability Information Exchange, where readers and authors share articles, opinions, and more.

delivered straight to your inbox