The Impact of Bearing Isolators on Life-Cycle Cost in Rotating Equipment

SEPCO Sealing Equipment

Posted 5/6/2025

Bearing isolators, advanced sealing devices for rotating equipment, offer significant advantages over traditional contact seals in reducing life-cycle costs. By enhancing bearing protection, minimizing maintenance, and improving operational efficiency, bearing isolators can yield substantial savings over the operational life of equipment such as pumps, motors, and gearboxes. This paper examines the technical and economic benefits of bearing isolators, supported by a case study and cost analysis, to demonstrate their role in optimizing life-cycle cost in industrial applications.

Rotating equipment, including centrifugal pumps, electric motors, and gearboxes, forms the backbone of industrial operations in sectors such as manufacturing, oil and gas, and chemical processing. Central to the reliability of these systems are bearings, which support shaft rotation and bear operational loads. However, bearings are vulnerable to contamination by water, dust, and other particulates, as well as lubricant loss, both of which accelerate wear and lead to premature failure. Traditional sealing methods, such as lip seals, often fail to provide robust protection, resulting in frequent maintenance and downtime. Bearing isolators, non-contact sealing devices, address these challenges by offering superior protection and longevity. This paper analyzes how bearing isolators influence life-cycle cost through reduced maintenance, extended equipment life, and improved energy efficiency.

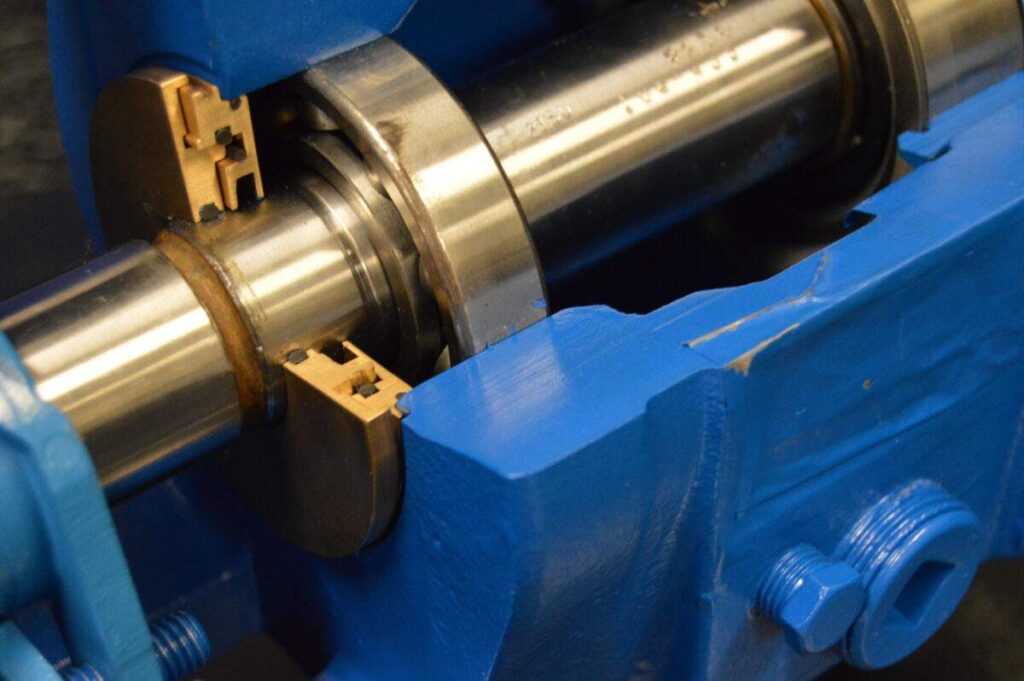

Technical Overview of Bearing Isolators

Bearing isolators are engineered sealing devices designed to protect bearings in rotating equipment by preventing ingress of contaminants and retaining lubricant. Unlike lip seals, which rely on physical contact with the shaft, bearing isolators employ non-contact designs, such as labyrinth or magnetic configurations, to eliminate wear. Key components include a stator (fixed to the housing), a rotor (rotating with the shaft), and a sealing interface that blocks contaminants while allowing minimal vapor exchange. Common materials, such as bronze, stainless steel, or advanced polymers, ensure durability in harsh environments.

The operational advantages of bearing isolators include:

Contaminant Exclusion: Labyrinth designs create tortuous paths that prevent ingress of water, dust, or abrasive particles.

Lubricant Retention: Isolators maintain lubricant integrity, reducing the risk of bearing starvation or contamination.

Non-Contact Operation: Eliminates frictional wear, extending seal life to match or exceed that of the equipment.

Versatility: Suitable for high-speed, high-temperature, or submerged applications with appropriate design modifications.

These characteristics directly impact life-cycle cost by reducing failure rates, maintenance frequency, and energy consumption compared to traditional seals.

Life-Cycle Cost Analysis

Life-cycle cost (LCC) encompasses all expenses associated with equipment from acquisition to disposal, including purchase, installation, operation, maintenance, and downtime costs. Bearing isolators influence several LCC components:

Maintenance Costs

Lip seals, costing approximately $20–$50 each, typically require replacement every 3–12 months due to wear. Each replacement incurs labor costs (e.g., $100/hour, 2–4 hours per event) and potential bearing replacement ($200–$1000 per bearing). In contrast, a bearing isolator, priced at $150–$500, often lasts 5–15 years with minimal maintenance. For a single pump operating in a dusty environment, lip seal replacements could cost $800–$2000 annually (2–3 failures/year), while a bearing isolator’s cost is amortized to $30–$100/year over a 10-year lifespan.

Downtime Costs

Unplanned downtime due to bearing failure is a significant LCC driver. In industries like pulp and paper or chemical processing, downtime costs range from $5,000 to $50,000 per hour, depending on production scale. A single bearing failure requiring 4 hours of repair could cost $20,000–$200,000 in lost production. Bearing isolators reduce failure frequency by maintaining lubricant integrity and excluding contaminants, potentially preventing 1–2 failures annually per unit.

Energy Efficiency

Lip seals generate frictional drag, increasing energy consumption by 0.5–1% in some motors. For a 100 HP motor operating 8,000 hours/year at $0.10/kWh, this translates to $300–$600/year in additional energy costs per motor. Bearing isolators, with negligible friction, eliminate this penalty, yielding cumulative savings in large fleets.

Equipment Longevity

By protecting bearings from contamination and lubricant degradation, isolators extend bearing life, delaying equipment replacement. A pump with a 10-year design life might require overhaul or replacement in 5–7 years with lip seals but operate reliably for 12–15 years with isolators, deferring capital expenditure.

Case Study: Pulp and Paper Mill

Consider a pulp and paper mill operating 20 centrifugal pumps in a humid, dust-laden environment. Each pump uses a 50 HP motor and is critical to production, with downtime costs of $10,000/hour. Historically, the pumps used lip seals, replaced twice yearly at $30/seal, with labor costs of $200/event. Bearing failures occurred annually on 25% of pumps, requiring $500/bearing and 4 hours of downtime per failure.

Lip Seal Scenario (Annual Costs per Pump):

Seal replacements: 2 × ($30 + $200) = $460

Bearing failures (25% probability): 0.25 × ($500 + $200 labor + $40,000 downtime) = $10,175

Energy penalty (0.75% increase): 50 HP × 0.746 kW/HP × 8,000 hr × $0.10/kWh × 0.0075 = $223

Total per pump: $10,858

Total for 20 pumps: $217,160

Bearing Isolator Scenario:

Initial cost: $300/pump, $50 installation (amortized over 10 years: $35/year/pump)

Failure rate reduced to 5% annually: 0.05 × ($500 + $200 + $40,000) = $2,035

Energy penalty: $0 (non-contact design)

Total per pump: $2,070

Total for 20 pumps: $41,400

Savings: $217,160 – $41,400 = $175,760/year. Over 10 years, savings exceed $1.75 million, excluding inflation and capital deferral benefits.

Implementation Considerations

While bearing isolators offer clear advantages, successful deployment requires attention to:

Application Matching: Select isolators suited to operating conditions (e.g., high-speed labyrinths for turbines, sealed designs for submerged pumps).

Installation Precision: Misalignment or improper fitting can compromise performance, necessitating trained personnel.

Initial Cost Justification: Higher upfront costs may face scrutiny from budget-conscious managers, requiring clear LCC analysis to demonstrate long-term savings.

Conclusion – Bearing Isolators

Bearing isolators significantly reduce the life-cycle cost of rotating equipment by minimizing maintenance, downtime, and energy expenses while extending equipment life. The case study illustrates savings of over $175,000 annually for a modest pump fleet, highlighting the scalability of these benefits in larger operations. For industries reliant on reliable rotating equipment, investing in bearing isolators represents a strategic approach to cost management, balancing initial expenditure against substantial long-term gains. Engineers and facility managers should prioritize isolators in equipment specifications and retrofit programs to optimize operational efficiency and financial performance.

SEPCO Fluid Sealing Solutions

We are your one-supplier solution for product design, recommendations, installation, and troubleshooting for both mechanical seals and compression packing.

From petrochemical, pharmaceutical processing, and water treatment to power generation, pulp and paper, SEPCO’s fluid sealing products are used daily in a wide range of applications. Our team of experts is dedicated to providing customized solutions that meet the unique needs of each of our customers, ensuring that they receive the right product for their specific requirements.

In addition, we’re dedicated to helping companies find opportunities to reduce the total cost of their fluid sealing and operational programs and improve their level of environmental responsibility by identifying areas of excess water and energy consumption.

Related Articles

OEE: Overall Equipment Effectiveness

What the Pump Was Designed to Do and Why it Doesn't Do it

What is Wrong with the Modern Centrifugal Pump?

Digging Up Savings: Go with the Flow

Chain Drive Design Recommendations

Classifying Chemicals to Assure Effective Sealing