Is Your Wet Scrubbing Tower Working?

Mike Sondalini, PWW EAM System Consultant

Posted 12/21/2023

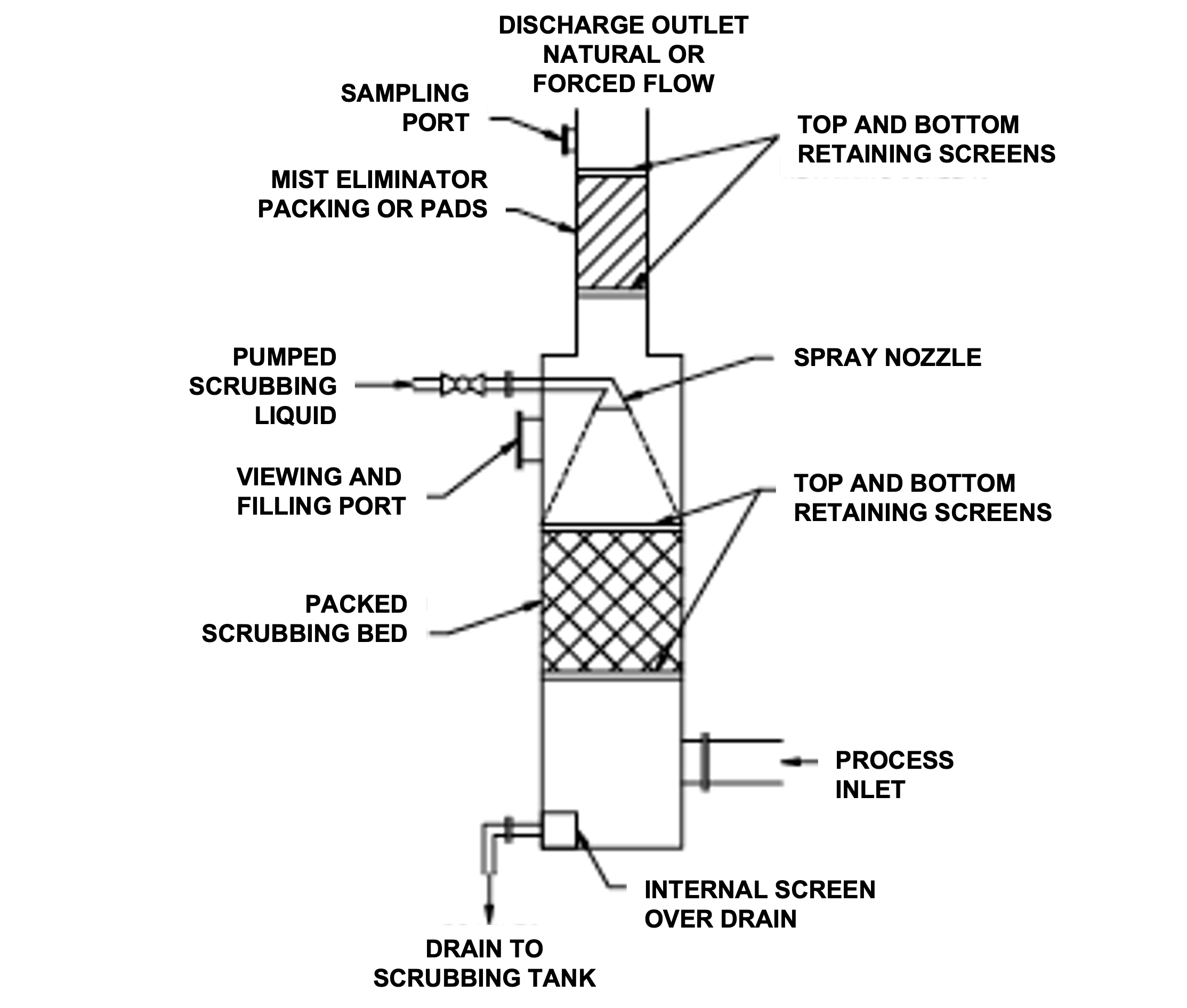

Is your scrubbing tower working? A wet scrubbing tower is used to clean odors, particles, mists, and vapors from a gas stream. The gas is forced through the tower. As it moves from inlet to outlet it is washed and cleaned. The washing is done with suitable chemicals that remove the active components in the gas flow. The gas is cleaned to environmentally acceptable levels and discharged to atmosphere.

Operation of a Wet Scrubbing Tower

The image below shows a simplified drawing of a packed scrubbing tower. The dirty gas comes in the bottom of the tower. Sprays within the tower wet the internals of the tower.

The gas is forced through a bed of packing ‘fill’ that breaks the gas flow into many small flow streams. The numerous gas streams pass around the wet fill and make contact with the scrubbing solution. The packing is usually a small twisted, convoluted plastic or metal wire shape.

During the contact active components in the gas are removed either by chemical reaction or, in the case of particles, by the drenching they receive from the sprayed liquid.

When the gas leaves the scrubbing bed it is wet. Liquid droplets and mist carried with the gas are then forced through another bed of packing, or mist elimination pads, to remove most of the moisture. As with the scrubbing bed, the elimination bed forces the wet gas to break-up into numerous small streams. The impact on the elimination bed material knocks the mist out of the gas stream. The dampness gathers on the bed material to form droplets that fall back into the tower.

The liquid sprayed into the tower must neutralize the components in the gas stream that are to be removed. For example, if the gas stream contained acid mist, the scrubbing liquid would be an alkaline solution of sufficient strength to neutralize all the acid. If there were concerns that the alkaline solution would itself carry-over into the atmosphere, it would be necessary to install an additional wash to clean the alkaline mist. A second tower spraying clean water could do this.

Performance Testing

The quality of the cleaned discharge gas reflects the scrubbing tower’s performance. To prove the tower is working properly, the discharge gas stream is sampled and tested for the amounts of the reactive components remaining in the flow. The test results must be below the relevant environmental guidelines.

Measuring the strength of the scrubbing solution can also be used to monitor the tower’s performance. As the gas stream is cleaned of the offending components the scrubbing solution changes its chemistry. This change in chemistry can be monitored and provides an indication of the tower’s performance.

The variables that affect scrubbing tower performance are:

- Residence time in the tower scrubbing bed. The gas flow needs to be sufficiently slow to provide time for the contaminants to contact the scrubbing liquid.

- Sufficient concentration of scrubbing reagent in the liquid to react with gas stream contaminant.

- Insufficient contact surface area because packing in the bed is missing, uneven or was never added to the tower.

Issues with Operating Wet Scrubbing Towers

Listed below are a number of important issues that need to be addressed when using packed-bed wet scrubbing towers.

- Blocked flow path forcing gas flow through only a part of the scrubbing bed. The packed bed must be uniform across and throughout its depth. Rat holes and blockages in the packing will allow the gas stream to bypass the cleaning or elimination processes.

- Blinded packing can occur if process contaminants start clogging up the passages between the packing elements. It may be possible to backwash the contamination or chemically remove it. Ensure the chemicals used do not destroy the packing.

- Blocked vent lines from process equipment to the scrubber can occur in processes containing fine, damp particulate. Keep the duct velocities high so the particulate cannot easily settle out and coat the walls. Where regular blockage occurs, it is necessary to find ways to backwash or chemically clean the duct regularly.

- The packing must be prevented from being blown out of the bed by abnormally high gas flows. A violent rush of gas created by the process reaction may dislodge the packing and even carry bits of it away. Retaining screens may be required on top of the bed. Ensure the mesh size and clearances around the screens do not allow fill to escape past them.

- Wet discharge from the tower will settle back onto neighboring equipment in the plant and hasten corrosion.

- Scrubbing liquid flows unevenly through the packed bed. The spray shape is critical to full and proper wetting of the packing in the bed. The spray cone needs to be a complete sheet of liquid impacting the inside wall of the tower just above the top of the scrubbing bed.

- A flooded scrubber drowns the scrubbing bed. Drainage from the tower back to the storage tank must be sufficient to always stay below the inlet nozzle to the tower. If the liquid level in the sump rises above the inlet nozzle it will flood back into the process.

- The materials used to make the tower and scrubbing circuit must be chemically and physically compatible with all the chemicals and conditions that will occur. Beware if the process temperature can get hot enough to melt plastic packing. If this occurs the melted plastic drops to the bottom of the bed and blocks it. The loss of packing and the blockage by the plastic stop the gas flow from being properly cleaned.

- Size the delivery ducting to the tower and the extraction fan to maintain mists and particles in suspension. Slope all ducting with sufficient fall to be self-draining and self-cleaning in the appropriate directions.

- Where possible it is better not to use a fan but instead totally seal the delivery ducting and use the natural pressures generated in the process to force the gas stream through the tower. This ‘natural pressure’ approach saves on equipment and maintenance and minimizes the gas discharge to the least amount necessary.

Mike Sondalini

Mike Sondalini is a Senior Consultant at PWWEAM System-of-Reliability. BEng(Hons), MBA, CPEng. As a consultant and trainer, Mike was able to present his insights to his clients, suggesting innovative approaches to plant and equipment reliability. Their feedback was resoundingly positive. Efforts which earned him an international reputation for articulate, out-of-the-box articles on plant and equipment reliability, life-cycle EAM, maintenance management, work quality assurance, and team building. After decades of dedicated research, Mike authored “Industrial Manufacturing Wellness: The Complete Guide to Successful Enterprise Asset Management” a revolutionary approach on how maintenance and physical asset management systems should be run, the book detailed who, what, where, when, why, and how outstanding reliability could be achieved. Each step based in scientific and mathematical understanding to ensure repeatability of results and optimal outcomes.

Related Articles

Spare Parts Management Indicators

6 Ways Outsourced Maintenance Saves

OEE: Overall Equipment Effectiveness

Mechanical Quality Assurance: The Next Progression of Reliability

Fixing Maintenance

What the Pump Was Designed to Do and Why it Doesn't Do it

What is Wrong with the Modern Centrifugal Pump?

Weibull Point Process Applied to Repairable Subsystems

Sorting Out Flexible Couplings

Safety Circuits, Force Guided Relays vs. General Purpose Relays

Chain Drive Design Recommendations

Anatomy of a Boiler Failure—A Different Perspective

Anatomy of a Hydraulic Pump Failure