Engineering Precision: Sensor Technologies and Maintenance Strategies for Extreme Environments

Kristi Perkins, MBA, Sales Engineer, Emerson Measurement Solutions

Posted 2/19/2026

Introduction: Understanding Pressure and Temperature Transducers

A pressure and temperature transducer is an instrument that measures physical conditions within a system and converts it into standardized electrical signals that can be monitored, recorded, or used for control and measurement. Pressure transducers quantify the force exerted by a gas or liquid on a sensing element or sensing surface. While temperature transducers detect changes in thermal energy within a material or process. In both cases, the transducer serves as the interface between the physical world and electronic measurement systems. Often, pressure and temperature are measured in a single transducer device.

At a functional level, pressure and temperature transducers rely on sensing elements that respond predictably to pressure or temperature changes. Mechanical deformation, electrical resistance shifts, voltage generation, or capacitance changes are then translated into analog or digital outputs that allow control systems and data acquisition hardware to interpret real‑world conditions with speed and accuracy.

Different Technologies Used in Sensors and Their Suitable Applications

Modern pressure and temperature sensors rely on a range of underlying measurement technologies, each optimized for specific performance requirements, environmental conditions, and lifecycle expectations. Selecting the appropriate technology requires balancing pressure range, temperature limits, stability, size constraints, media compatibility, and long‑term reliability.

Tube-Type Sensing Technologies

Tube-type sensing technologies measure pressure by detecting the elastic deformation of a thin‑walled metal tube. As pressure is applied, the tube experiences a predictable strain that is converted into an electrical signal using strain gauges. The cylindrical geometry distributes stress evenly, allowing tube‑type sensors to withstand extremely high pressures.

Tube-type sensors are commonly manufactured from high‑strength alloys such as nickel‑based superalloys or stainless steels. Because the sensing element and pressure boundary are the same structure, these designs minimize leak paths and offer excellent long‑term stability. Tube-type can be analog or digital output, depending on the application.

Design Tradeoffs

Tube‑type sensors excel at very high pressures and harsh environments, but their mechanical stiffness limits sensitivity at low pressure ranges.

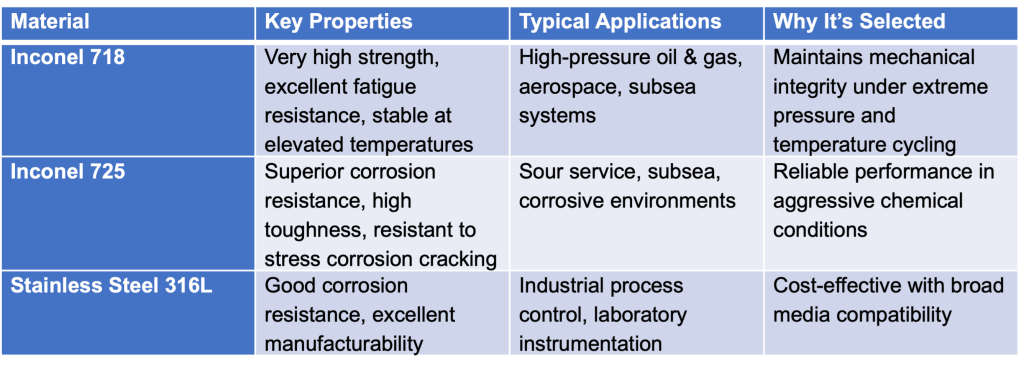

Material selection is just as critical as sensing technology, as it directly affects pressure containment, temperature tolerance, corrosion resistance, and long‑term stability.

Common Materials Used in Pressure and Temperature Transducers

Capacitive Pressure Sensors

Capacitive sensors measure pressure by detecting changes in capacitance between a flexible diaphragm and a fixed electrode. They provide excellent resolution at very low pressures.

Design Tradeoffs

Capacitive sensors are sensitive to contamination and typically require additional protection in harsh or high‑pressure environments.

Thin-Film and Strain-Gauge Technologies

Thin‑film and strain‑gauge sensors measure pressure by monitoring resistance changes in metallic films bonded to a pressure‑sensing diaphragm.

Design Tradeoffs

Accuracy can be influenced by installation stress and temperature gradients if not properly compensated.

RTDs (Resistance Temperature Detectors)

RTDs measure temperature through predictable resistance changes in metallic elements, typically platinum, and are valued for accuracy and long‑term stability.

Design Tradeoffs

RTDs have slower response times and limited maximum temperature capability compared to thermocouples.

Thermocouples

Thermocouples generate a voltage based on the Seebeck effect using two dissimilar metals and operate across extremely wide temperature ranges.

Design Tradeoffs

Thermocouples trade precision for durability and temperature range.

Maintenance of Sensors and the Associated Complexities

Even the most advanced sensors require ongoing maintenance to ensure long-term accuracy and reliability. Factors such as sensor drift, environmental exposure, and material aging all influence performance over time. To mitigate these effects, it is critical to operate sensors within the manufacturer’s specified pressure, temperature, and environmental limits, as operating beyond these boundaries can significantly reduce sensor lifespan and measurement integrity.

Best practices for maintaining sensor performance include condition-based calibration, historical data trending, and proactive lifecycle planning, particularly in applications where sensor access is limited or where failure presents high operational risk. In many industrial environments, annual recalibration is recommended; however, this is not always feasible. Sensors deployed in downhole and subsea wells, space and satellite systems, or critical industrial machinery may operate for extended periods without service access. In these cases, selecting a sensor with proven long-term stability and repeatability becomes essential.

A common mistake made in instrumentation applications is operating sensors beyond their rated pressure or temperature specifications. While this may provide short-term flexibility, it often leads to accelerated drift, permanent calibration shifts, or mechanical damage. Over time, these issues can introduce significant measurement error, ultimately resulting in reduced system performance, unplanned downtime, and potential revenue loss.

Conclusion – Pressure and Temperature Transducers

Selecting the right sensor technology and maintaining it effectively are inseparable challenges. By aligning sensing technology, material selection, specifications, and maintenance strategy with application demands, engineers can ensure reliable measurement in even the most extreme environments.

References:

Emerson. (2018). Material selection and compatibility considerations for Rosemount™ pressure transmitters (Tech. Note No. 00840-0100-3045, Rev. CB). https://www.emerson.com/documents/automation/technical-note-material-selection-considerations-for-pressure-transmitters-rosemount-en-77770.pdf

Gadepatil, S. (2025, November 27). 4 types of pressure transmitters | Working principles and key differences. Instrumentation Blog. https://www.instrumentationblog.in/types-of-pressure-transmitters/

Statler, M. (2026). Industrial pressure sensors [Blog post]. Advanced Technology Services. Industrial Pressure Sensor Types & Applications | ATS

Kristi Perkins

As a Sales Engineer II at Emerson, Kristi leverages her MBA and experience in the semiconductor industry to provide tailored solutions that enhance operational efficiency for clients. She manages the entire sales process from consultation to post-sales support, ensuring customer satisfaction and fostering long-term relationships.

She has a proven track record of developing automation strategies for manufacturers to optimize productivity and drive business success. She collaborates closely with clients to implement cutting-edge automation solutions in the manufacturing sector, leveraging her industry expertise to accelerate digital transformation and enhance efficiency in manufacturing processes. She is also skilled in continuous improvement initiatives within MRP/ERP systems and value stream mapping.

Related Articles

How do I Test Relays and Contactors?

The Cost of Producing Electricity

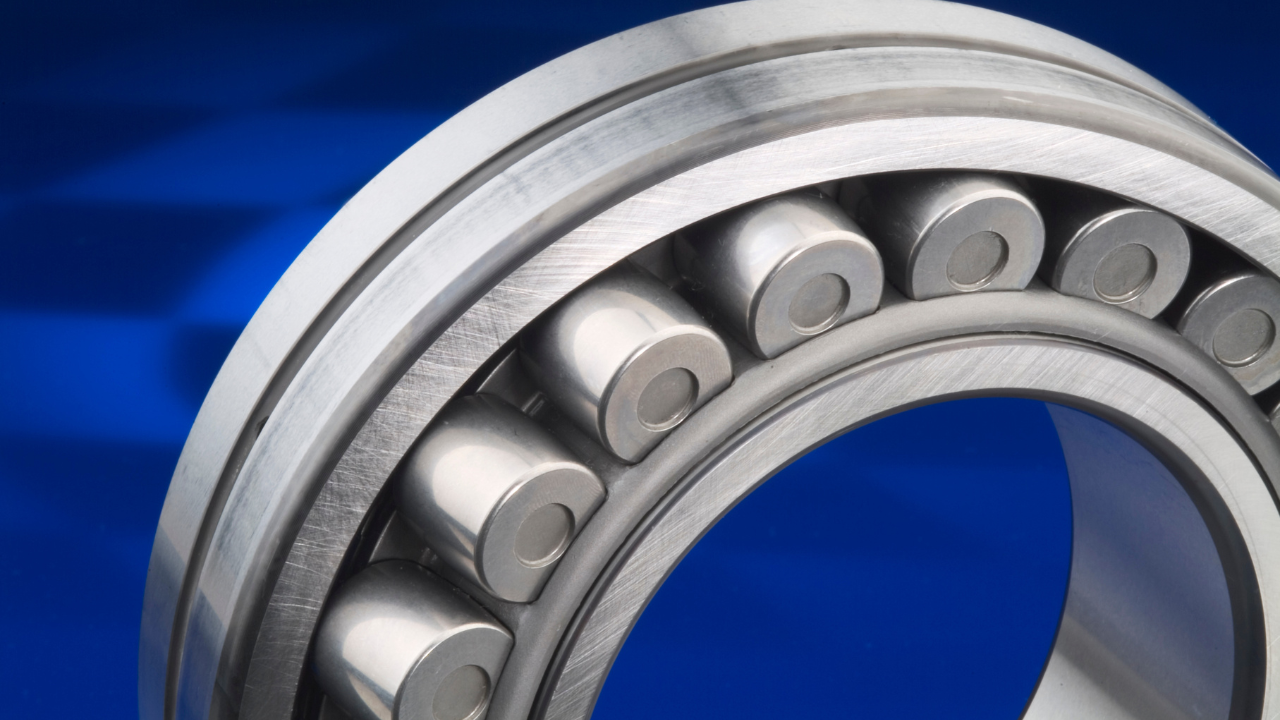

Get Your Bearing on Brinelling

Pump Cavitation Solutions: Polymeric Solutions for Pumps Suffering from Cavitation

Developing an Effective Electric Motor Testing Program

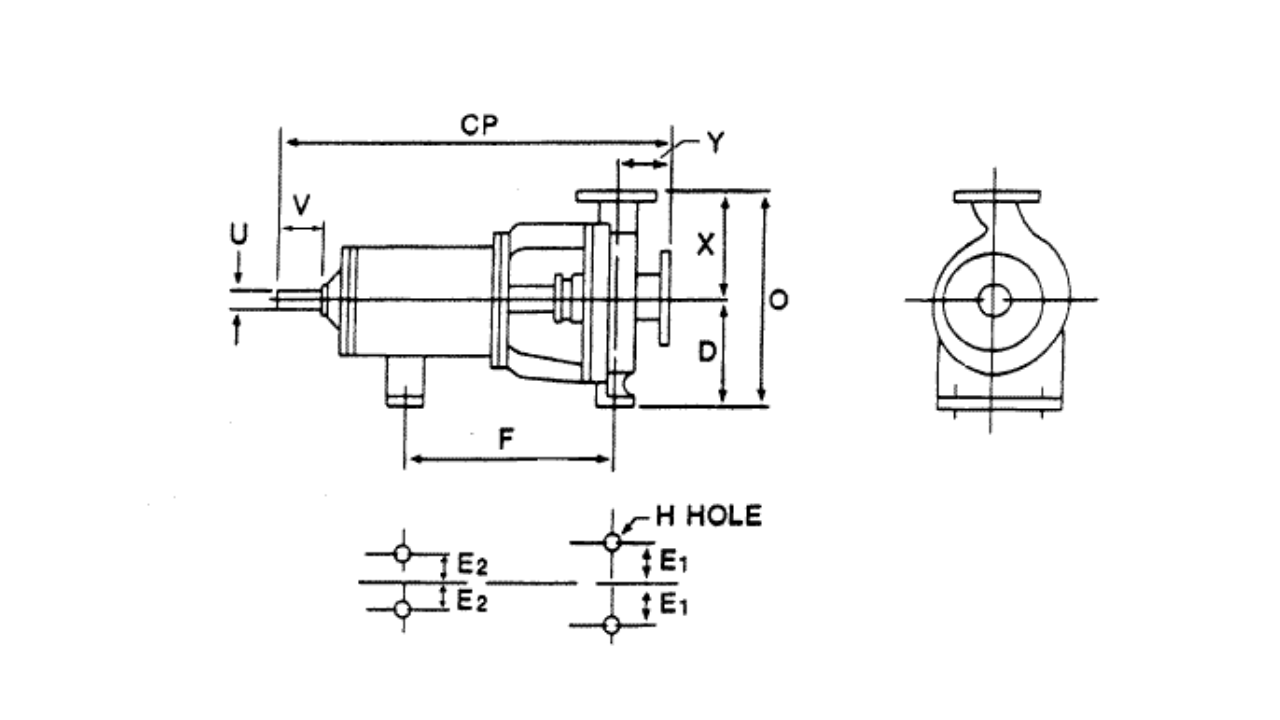

The ANSI Pump Standard 14-5