Diagnosing a Bent Shaft

Alan Friedman, Zenco Vibrations

Posted 11/13/2023

Read or share the article on ZencoVibrations.com

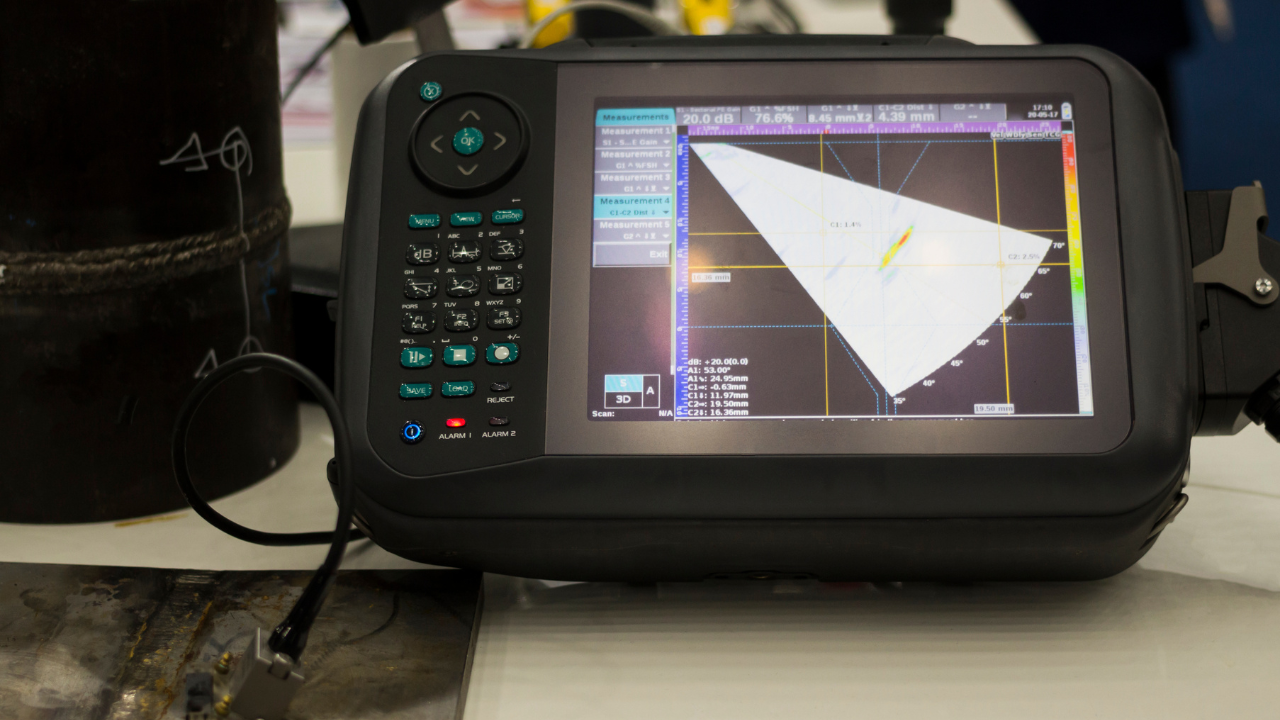

Diagnosing a bent shaft with vibration analysis is easy to do, especially when you can visualize its movement using 3D animations.

A bent shaft causes shaft rate vibration (1x) in all three axes. Depending on the location of the bend, one might also see an elevated 2x in the Axial direction. Harmonics of 1x are also possible.

Be careful not to mistake a high 1x H and 1x V for unbalance. Both are indicated by an increase in shaft rate vibration in the vertical and horizontal directions. One way to tell the difference is to consider which one is more likely. If you are monitoring a fan in a dirty environment, the fan blades are bound to get dirty and go out of balance, so check this first. Clean the blades, balance the unit. If the problem doesn’t go away, then consider other possible causes such as a bent shaft.

A bent shaft also results in shaft rate (1x) vibration in the axial direction. Notice in the animation below how the top and bottom of the end of the shaft moves to the right and the left, out of phase with each other, as it bends. The same thing is happening on the left and right side of the shaft at the end. 1x Axial vibration and similar phase relationships are also common in a cocked bearing, so it can be difficult to tell the difference between this and a bent shaft.

2x vibration in the Axial direction is also common but depends on the location of the bend. The cause of this frequency is difficult to visualize.

As noted earlier, bent shaft can cause an elevated 1x V, H just like unbalance. One way to differentiate bent shaft from unbalance is by measuring phase. The giveaway is that the 1x Axial vibration will be out of phase on both ends of the bend. But wait, this pattern could also describe angular misalignment! So which is it? Well, consider that when you have angular misalignment, it’s almost like you are forcing the shaft to bend at the coupling. This is why it looks similar. Angular misalignment can also cause an elevated 2x Axial. The way to tell the difference is to consider where you are taking the readings, and which defect is more likely. If you are taking the readings on either side of a coupling, misalignment would be the more likely cause. If you are taking the readings on two fan bearings and there is no coupling then a bent shaft could explain the vibration pattern you see.

Conclusion – Diagnosing a Bent Shaft with Vibration Analysis

Vibration patterns for different faults can look similar to each other. This is why it is always best to start with the machine, consider what faults are most likely and then take data in the proper test points and axes to find the most likely faults. Unbalance in an over hung fan also causes a high 1x A, V, H. If the fan is mounted directly on the motor shaft then this vibration pattern obviously doesn’t indicate angular misalignment (because in this example there is no coupling to be misaligned). And as we mentioned before, fans get dirty and go out of balance, so which is more likely, a dirty fan or a bent shaft? See what I’m getting at? Don’t look at the peaks in the spectrum and then try to figure out what they mean, rather start with the machine and look for specific faults it can have in the order of which is most likely.

It can get complicated, but 3D animations make it easier to visualize what is going on, especially when you compare to other fault conditions and have the concepts explained to you by an experienced instructor.

Want to Learn More? Come to one of my vibration courses!

Email me at mailto://ZencoVibe@gmail.com to organize a private course live online or on-site. You can also email me to pay for a public course with a purchase order. Click this link for the schedule.

Alan Friedman

Alan, aka the Vibe Guru, has over 30 years of vibration analysis experience, He has trained 1000’s of students around the world up to Category IV. One of the things that makes Alan a great teacher is his ability to teach people where they are at. Whether you are a math challenged millwright, an engineer or a PhD, Alan will challenge you without overwhelming you. If you are interested in condition monitoring you can also check out his book: Audit It. Improve It! Getting the Most from your Vibration Monitoring Program or hire him for an on-site program audit.

Related Articles

Vibration & Ultrasound Technologies: A Possible Integrated Inspection Tool?

Vibration Pen, Shock Pulse Measurement (SPM), & Vibration Analysis - What's the Difference?

Vibration Analysis Reveals Poor Motor Mounting Structure

Ultrasonic Leak Detection in Heat Exchangers

Using Corrective Maintenance Work Plans to Improve Plant Reliability

Understanding The Basics Of Balancing & Measuring Techniques

Understanding Shaft Alignment: Thermal Growth

Ultrasound for Better Lubrication

Top Ten Ways Not to be World Class at Machinery Lubrication

Tips For Blower Maintenance

3 Important Words for Success in Lubrication and Oil Analysis

The Truth Behind Misalignment Vibration Spectra of Rotating Machinery

The Hidden Cost of Oil Changes

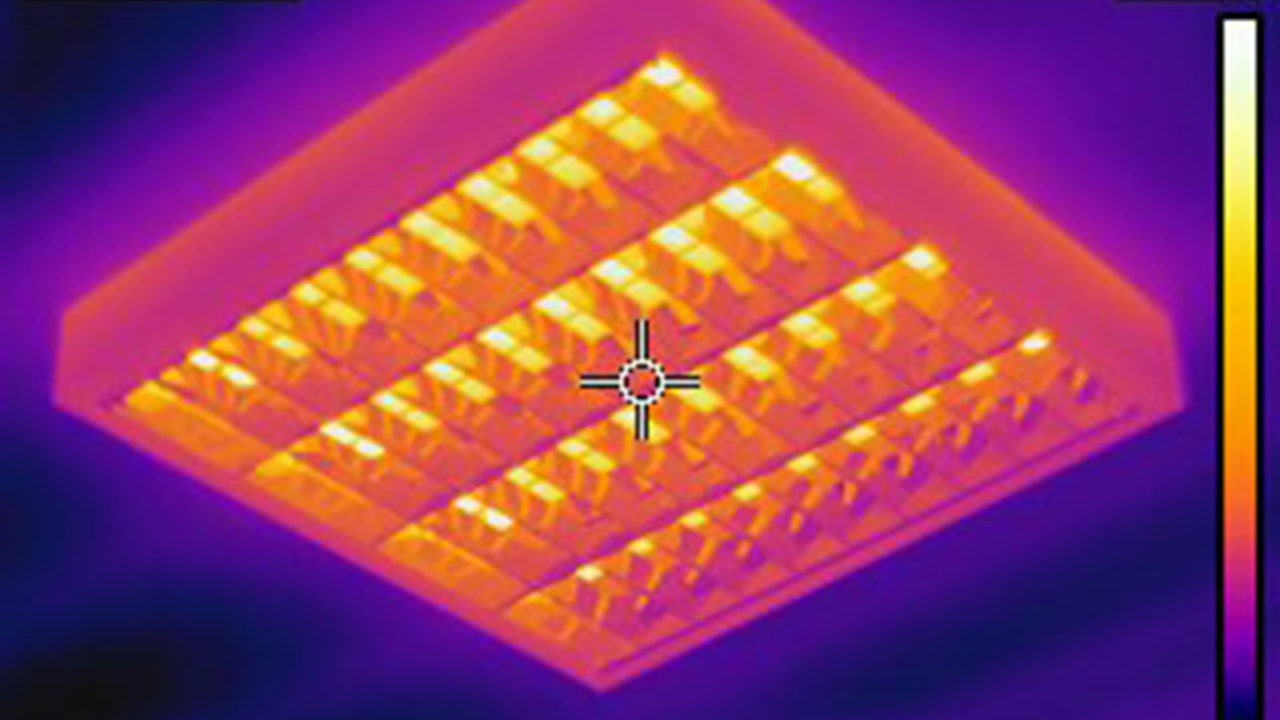

The Effectiveness Equation for Infrared Predictive Maintenance Programs

The Case of Successful Filtration and Oil Analysis Implementation

The Basics of Lubrication PM Procedures