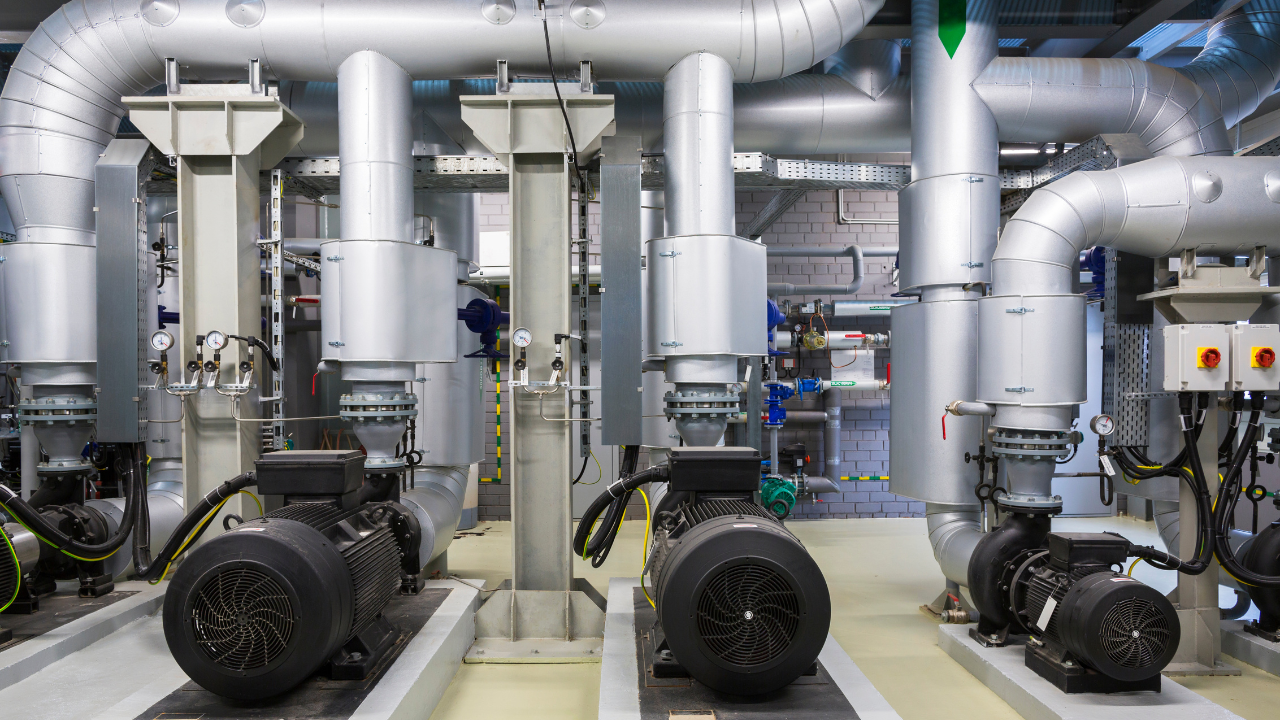

Maintenance Equipment: Basics of Centrifugal Pumps

Mukesh Sahdev, www.cheresources.com

Centrifugal-Pumps

Click here to download the full pdf.

Mukesh Sahdev, www.cheresources.com

Related Articles

Tips For Blower Maintenance

The article is intended to provide a few tips for blower maintenance to plant maintenance professionals in reducing the downtime and increasing the reliability of blowers. Generally the apparent reasons for blower failure are: Failure of Bearings and High Vibrations

The article is intended to provide a few tips for blower maintenance to plant maintenance professionals in reducing the downtime and increasing the reliability of blowers. Generally the apparent reasons for blower failure are: Failure of Bearings and High Vibrations

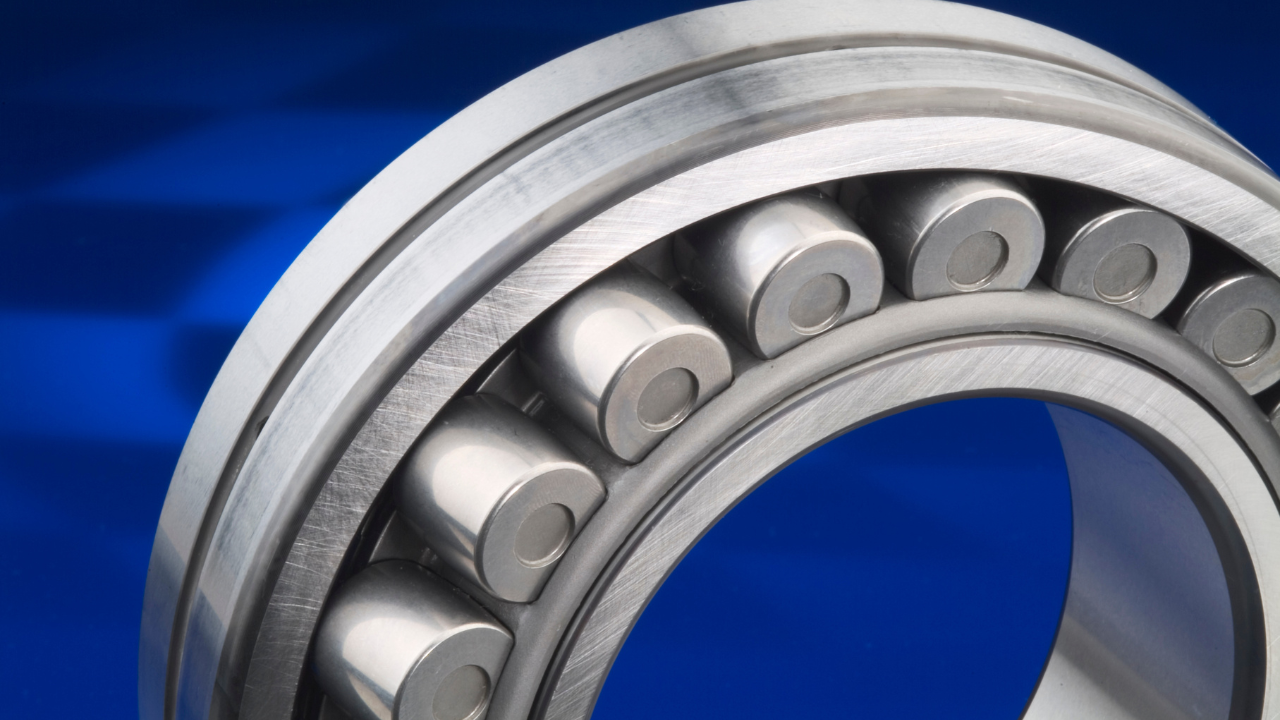

Get Your Bearing on Brinelling

Greg Mecomber of IDCON INC sits down with several industry experts from Regal Rexnord to discuss brinelling failures, true/false brinelling, maintenance, and prevention.

Greg Mecomber of IDCON INC sits down with several industry experts from Regal Rexnord to discuss brinelling failures, true/false brinelling, maintenance, and prevention.

The 7 Secrets of Pump Reliability

Contrary to popular opinion, a centrifugal pump is not designed to develop a specific head at a certain capacity as requested by the pump purchaser. In fact a pump is designed and built to produce a whole range of head-capacity conditions as identified by it’s performance curve. The pump will operate on that curve if it is driven at the designated speed.

Contrary to popular opinion, a centrifugal pump is not designed to develop a specific head at a certain capacity as requested by the pump purchaser. In fact a pump is designed and built to produce a whole range of head-capacity conditions as identified by it’s performance curve. The pump will operate on that curve if it is driven at the designated speed.

Adhesives Assure Fastener Reliability

Threaded fasteners set and hold tolerances on assemblies ranging from light-duty equipment to heavy machinery. Loosening is one of the major causes of industrial equipment failure, and results in millions of dollars worth of unscheduled downtime costs each year. In many cases, fasteners that self-loosen during equipment operation may contribute to wear and fatigue, and result in poor operating tolerances, misalignment and even catastrophic equipment failure. Various types of differential stresses such as vibration and shock, thermal expansion and contraction, and micro-movement reduce clamping force on the assembly and ultimately cause failure.

Threaded fasteners set and hold tolerances on assemblies ranging from light-duty equipment to heavy machinery. Loosening is one of the major causes of industrial equipment failure, and results in millions of dollars worth of unscheduled downtime costs each year. In many cases, fasteners that self-loosen during equipment operation may contribute to wear and fatigue, and result in poor operating tolerances, misalignment and even catastrophic equipment failure. Various types of differential stresses such as vibration and shock, thermal expansion and contraction, and micro-movement reduce clamping force on the assembly and ultimately cause failure.

How to Label and Number Equipment for Easy Identification

Clear labeling of equipment numbers in the field is a quick way to improve many aspects of your work management processes. Some benefits of field labeling equipment include: better work identification, less risk of lockout/tagout mistakes, faster troubleshooting of process upsets, and more efficient preventative maintenance routes.

Clear labeling of equipment numbers in the field is a quick way to improve many aspects of your work management processes. Some benefits of field labeling equipment include: better work identification, less risk of lockout/tagout mistakes, faster troubleshooting of process upsets, and more efficient preventative maintenance routes.

How do I Test Relays and Contactors?

I often hear the words “relays” and “contactors” used seemingly interchangeably, but there must be a technical difference, right? So, I took a quick trip to Rexel Automation Solutions in Salisbury, MD to meet with Nate Titus, Account Manager, and get the skinny on these beloved but sometimes pesky industrial workhorses.

I often hear the words “relays” and “contactors” used seemingly interchangeably, but there must be a technical difference, right? So, I took a quick trip to Rexel Automation Solutions in Salisbury, MD to meet with Nate Titus, Account Manager, and get the skinny on these beloved but sometimes pesky industrial workhorses.