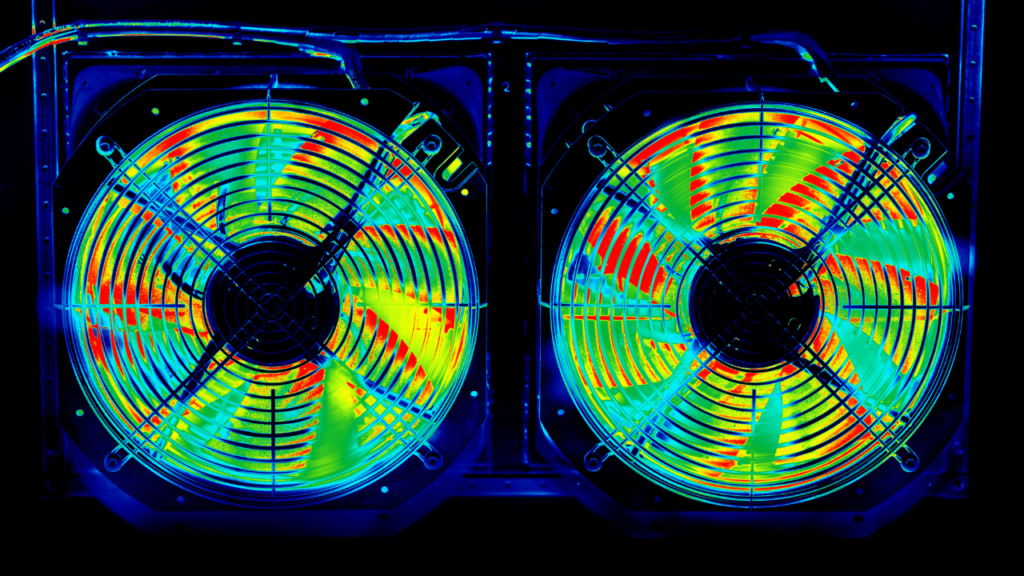

Cooling the Industrial Workplace

Excessive heat in a manufacturing or warehouse environment has negative effects on workers, production levels and even the quality of produced or stored goods. This is a growing concern because today’s North American industries are being pressed hard to match offshore production options. Fortunately there are plant cooling solutions that can solve this problem.

Cooling the Industrial Workplace Read More »