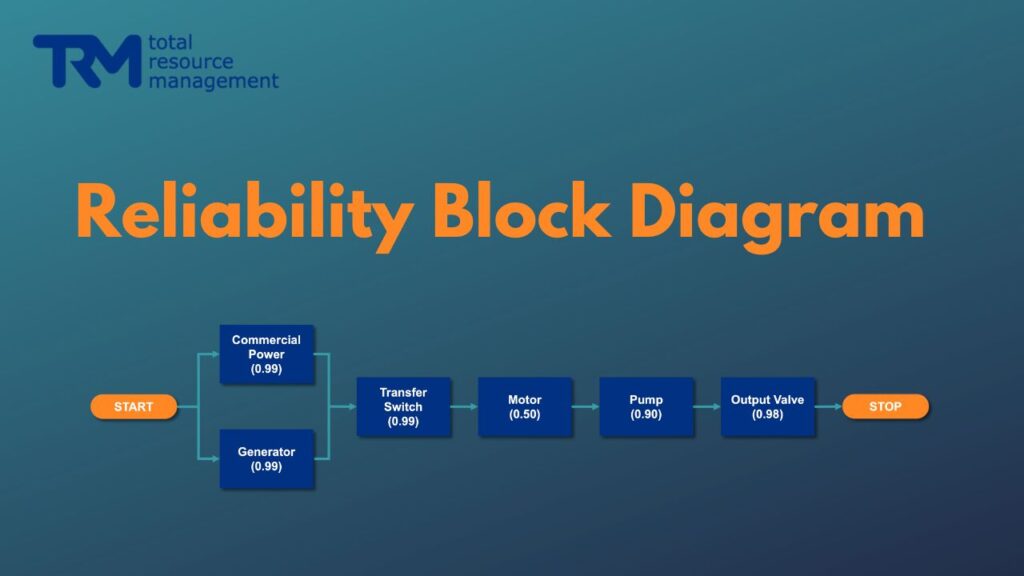

Back to Basics: Understanding Reliability Block Diagrams (RBD)

Reliability Block Diagrams have been around for a very long time, helping system engineers understand how the various elements, and their relationships, could impact the overall reliability and operation of the system. Taking the effort to diagram a system logically can provide great insight into where the weak links are. In some cases, an RBD can expose that your assumed redundancies are not actually as effective as you think they are.

Back to Basics: Understanding Reliability Block Diagrams (RBD) Read More »