Hydraulic Cylinder Failure Caused by the Diesel Effect

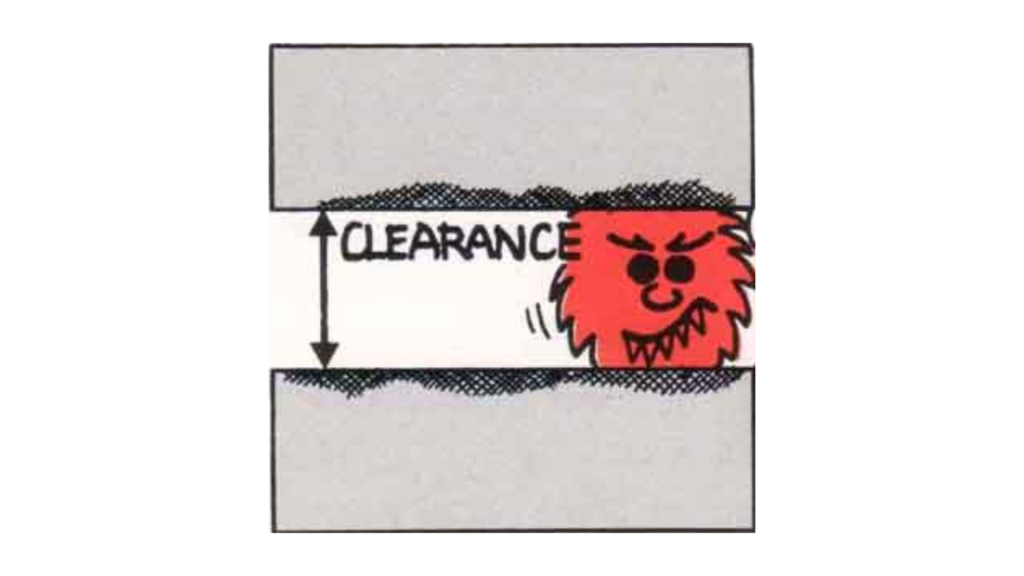

I was recently engaged by a client to conduct failure analysis on a large (and expensive) hydraulic cylinder off an excavator. This hydraulic cylinder had been changed-out due to leaking rod seals after achieving only half of its expected service life. Inspection revealed that apart from the rod seals, which had failed as a result of the ‘diesel effect’, the other parts of the hydraulic cylinder were in serviceable condition.