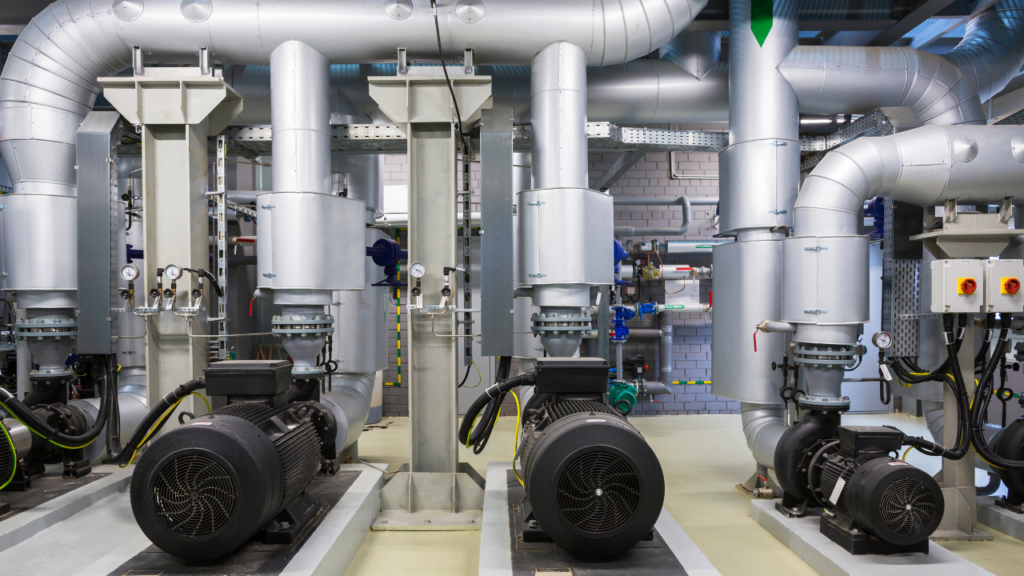

How Green is Green When it Comes to Using Everyday Industrial Cleaning Products for Plant Maintenance?

The answer is, it depends. For example, a traditional cleaner/degreaser, of which there are literally hundreds on the market, generally does an adequate job of cleaning. However – and this is an ongoing problem – the majority of them basically move the contamination from one location to another. The result? This cost of hydrocarbon removal is added to the clean-up process, plus your employees could be at risk of additional from toxins in the cleaner. So, how do you clean, provide a safe product for your employees and contribute to an active pollution prevention program?