How to Extend Bearing Life

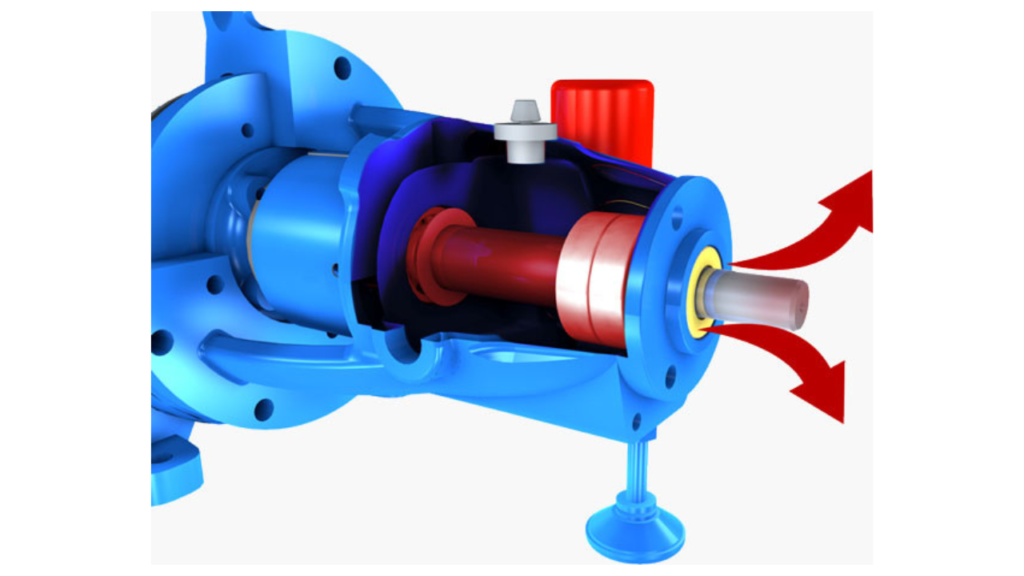

Research into bearing failures1 shows that just over half of them are a result of contamination of the bearing oil. Clearly, it is essential to ensure that this is minimized and, if possible, eliminated to achieve the optimum bearing life necessary to improve equipment reliability.