Define and Measure KPIs and Goals for Condition Based Maintenance

Alan Friedman, Cat IV, CRL, CMRP, Author; Founder/CEO of Zenco Vibration Experts

Posted 9/12/2024

It’s common for people to buy a new tool, a new service or a new product with a vague idea that it will somehow solve all of their problems. Oftentimes the sales and marketing people promoting this product will do their best to give this impression. Sometimes they oversell the product, sometimes not but the general gist is if you buy it then all will be well.

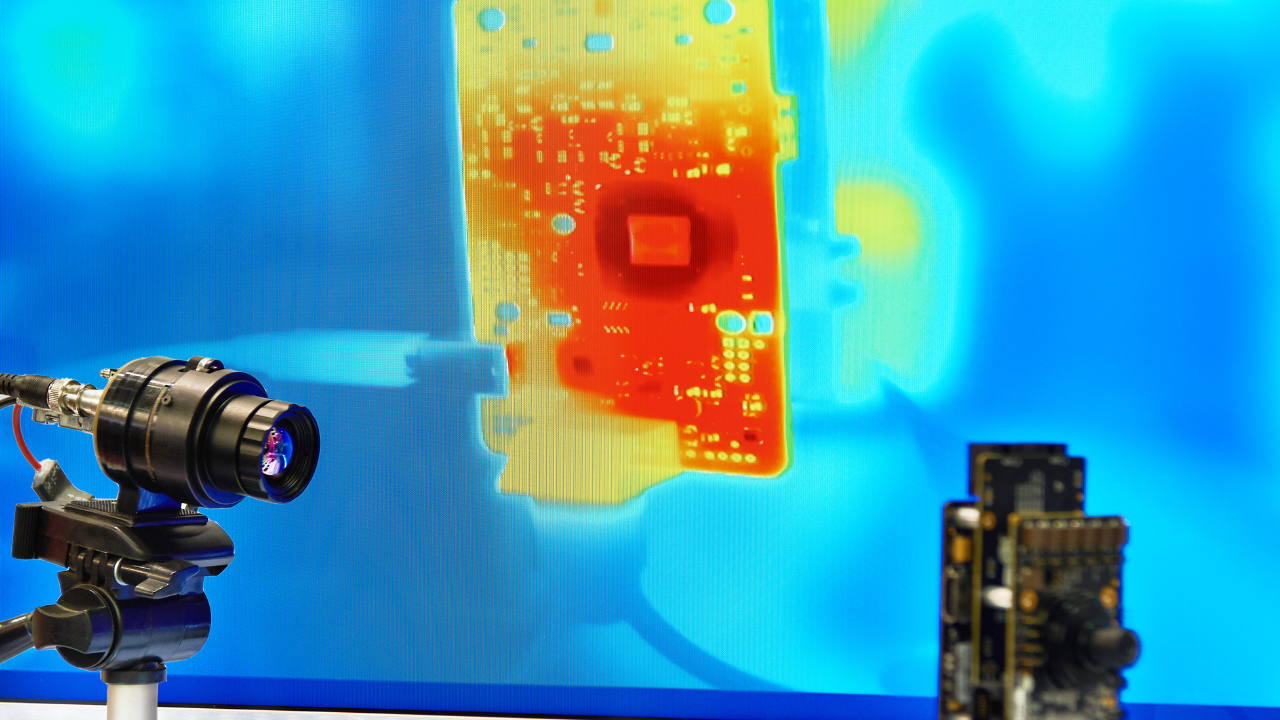

I find this to be the case with condition monitoring technologies. People purchase a new IR camera or an ultrasound camera with an understanding that they need this technology but an unclear understanding of exactly why they need it, where they will use it and how they will measure the benefits or return on investment (ROI) of having purchased it.

Define and Measure KPIs

I think it is important to be crystal clear about your goals when implementing any new technology or updating any process or procedure. Use the power of the “why” question to drill down to the real reason “why” you need to use this technology. What problem does it solve? Why do we need to solve this problem? How will we measure the financial benefits of having solved this problem? At the end of the day, since you are running a business, it always comes down to money and ROI. Even if it is a matter of safety or reliability, at the end of the day, poor practices cost money. Define and measure KPIs.

Key Performance Indicators (KPIs)

Sometimes people are fairly clear with regards to their goals however, this is not enough. You need to actually measure if you are meeting your goals or not. This is why we need KPIs. We are in an era of big data and there are tons of products available to help us analyze and visualize the data we collect. There are fancy dashboards and databases and ways of moving data around. The problem is, people don’t seem to be making good use of the information available to them. Why? I think it is because the goals are not clearly defined. If you don’t have clearly defined goals, how will you know what measure to see if you are reaching these goals or not?

Because this is such an important aspect of running any type of program or purchasing any new technology, I spend at least a 1/2 day in my vibration courses covering these concepts. It is not enough to be really good at interpreting vibration graphs to identify machine problems. You need to understand the bigger picture, cost benefits of doing so, For example, would it make sense to spend a day analyzing data from a $300 throw-away motor to figure out what specific problem it has? (Sometimes yes, sometimes no)

Measuring KPIs

Key Performance Indicators (KPIs) help you determine the effects or outcomes of your efforts. Are you really getting a benefit from your condition monitoring program? How can you know if you do not measure?

What KPIs should you measure? Well, that depends on the goals of your program. Is your condition monitoring program focused on gaining the benefits associated with better repair planning or is it more focused on avoiding catastrophic failures? How do repair decisions effect labor planning and overtime? How does repair planning effect the process of purchasing replacement parts? How does it effect production and meeting production goals?

When machines fail they can cause accidents, injuries and environmental consequences. These can lead to lawsuits and fines. These are additional examples of KPIs that can be measured, especially if the goal of your monitoring program is primarily focused on minimizing risk.

You might also be interested in measuring the monitoring program itself. How many assets were tested? What types of problems were detected? What was the compliance to the test schedule?

See a complete list of KPIs on my website and download a PPT presentation

Some KPIs to Consider

- Wrench Time – How does CBM make labor usage more efficient?

- Overall Equipment Effectiveness (OEE) – How does CBM lead to increases in production?

- Ratio of planned / unplanned work – Are you in a reactive mode?

- Hours spent on corrective work identified by CM technologies / hours spent taking CM measurements – are we identifying enough problems with our measurements?

- Maintenance costs / asset value – How much are we spending on maintenance overall relative to the value of our assets? Are we reducing maintenance costs?

- Time from fault diagnosis to repair – Are we finding things early enough to benefit from better planning?

- Mean Time Between Failures – Although not directly related to CBM, we want to make sure we are improving reliability

Benefits of Condition Based Maintenance

Condition based maintenance offers a large array of benefits if done correctly. It is not enough however to know we are doing a good job. We have to be clear about our goals and we have to be clear about how we are going to measure if we are meeting our goals or not. There are all sorts of fancy software platforms with dashboards that can help us define and measure KPIs, and track and visualize them, but we have to actually use them!

Alan Friedman

Alan, aka the Vibe Guru, has over 30 years of vibration analysis experience, He has trained 1000’s of students around the world up to Category IV. One of the things that makes Alan a great teacher is his ability to teach people where they are at. Whether you are a math challenged millwright, an engineer or a PhD, Alan will challenge you without overwhelming you. If you are interested in condition monitoring you can also check out his book: Audit It. Improve It! Getting the Most from your Vibration Monitoring Program or hire him for an on-site program audit.

Related Articles

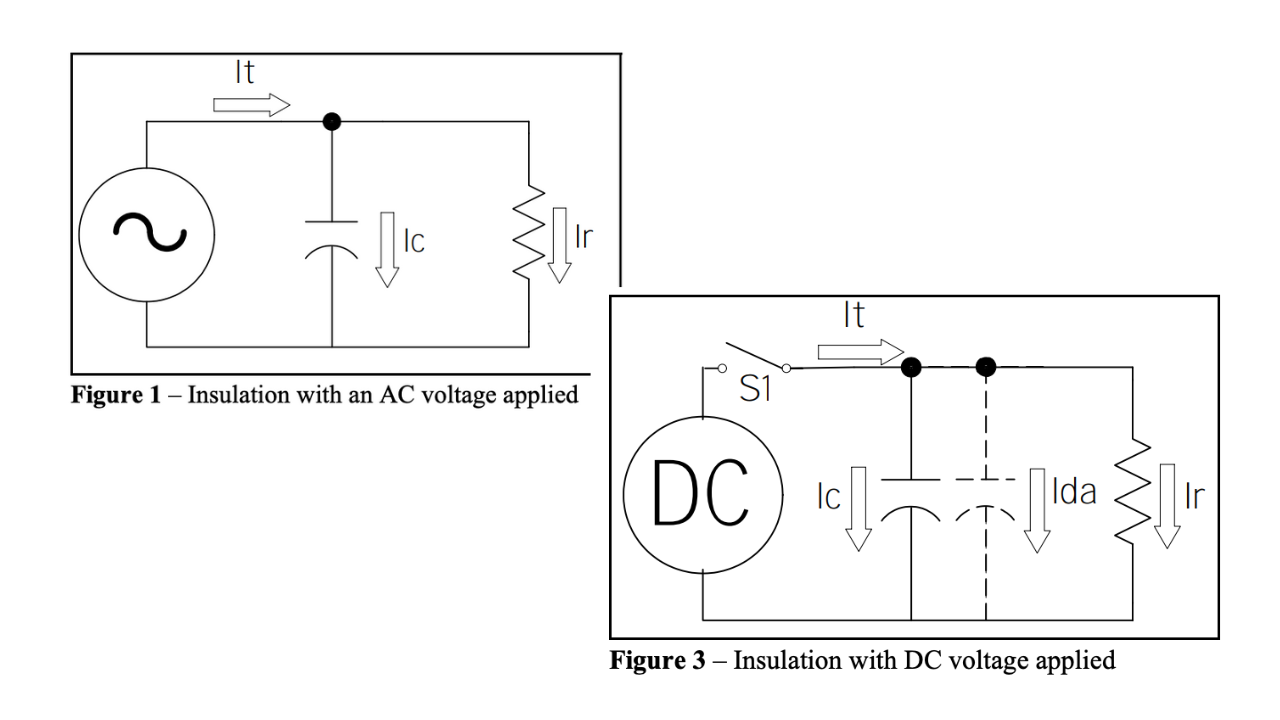

Principles of Insulation Testing

Top Tips for Selecting Pressure Measurement Transmitters

Gearbox Diagnostics Fault Detection

What is Vibration?

Why Record? Infrared Video

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera