Why CBM Should Be Considered a Critical Component of Any Business’s Asset Maintenance Strategy

Charlie Green, Senior Research Analyst, Comparesoft

Posted 07/13/2023

In an era characterized by rapid technological advancements and burgeoning data, industries are constantly seeking methods to enhance efficiency, minimize downtime, and optimize asset utilization. One such method that has emerged at the forefront is Condition Based Maintenance (CBM); a sophisticated, data-driven approach to asset maintenance. CBM is a rapidly growing field, with the machine condition monitoring market projected to escalate from $2.38 billion in 2018 to an estimated $3.5 billion by 2024. With recent data suggesting that unexpected downtime costs industrial businesses upwards of $50 billion, understanding the benefits that CBM can bring to a business’s maintenance strategy is critical. As a cornerstone of a comprehensive maintenance strategy, CBM is instrumental in facilitating informed decision-making, thereby amplifying the efficacy and precision of maintenance initiatives for businesses across all sectors.

How Does Condition Based Maintenance Work?

Condition based maintenance (CBM) operates by performing maintenance tasks based on the actual state of equipment. It’s a strategy that optimizes maintenance resources by performing work only when necessary.

The crux of CBM lies in real-time data collection and analysis. Sophisticated sensors are installed on equipment to monitor and collect data on various parameters like temperature, vibration, and pressure. For example, businesses might install a sensor that measures the vibrations of a rotating piece of equipment. Over time, as the equipment degrades and begins to misalign, an increase in vibration occurs. The installed sensor can alert you when the amount of vibration crosses a set limit, indicating that the part should be replaced soon.

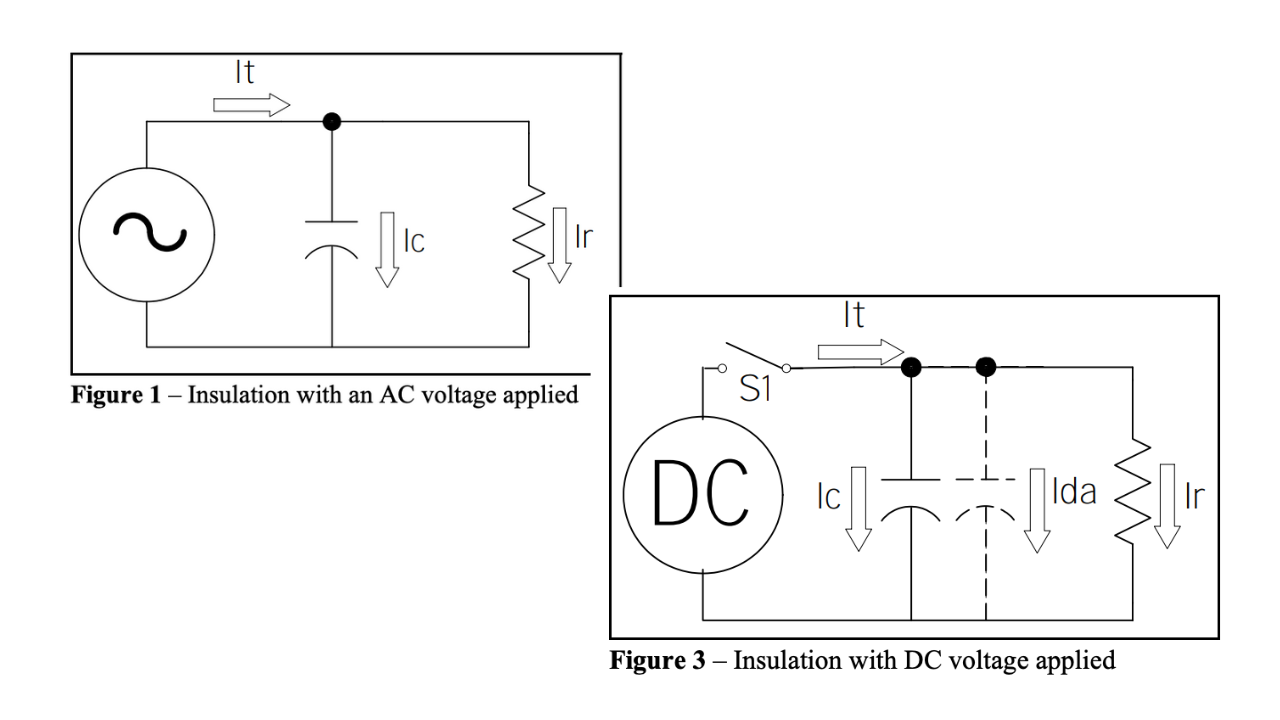

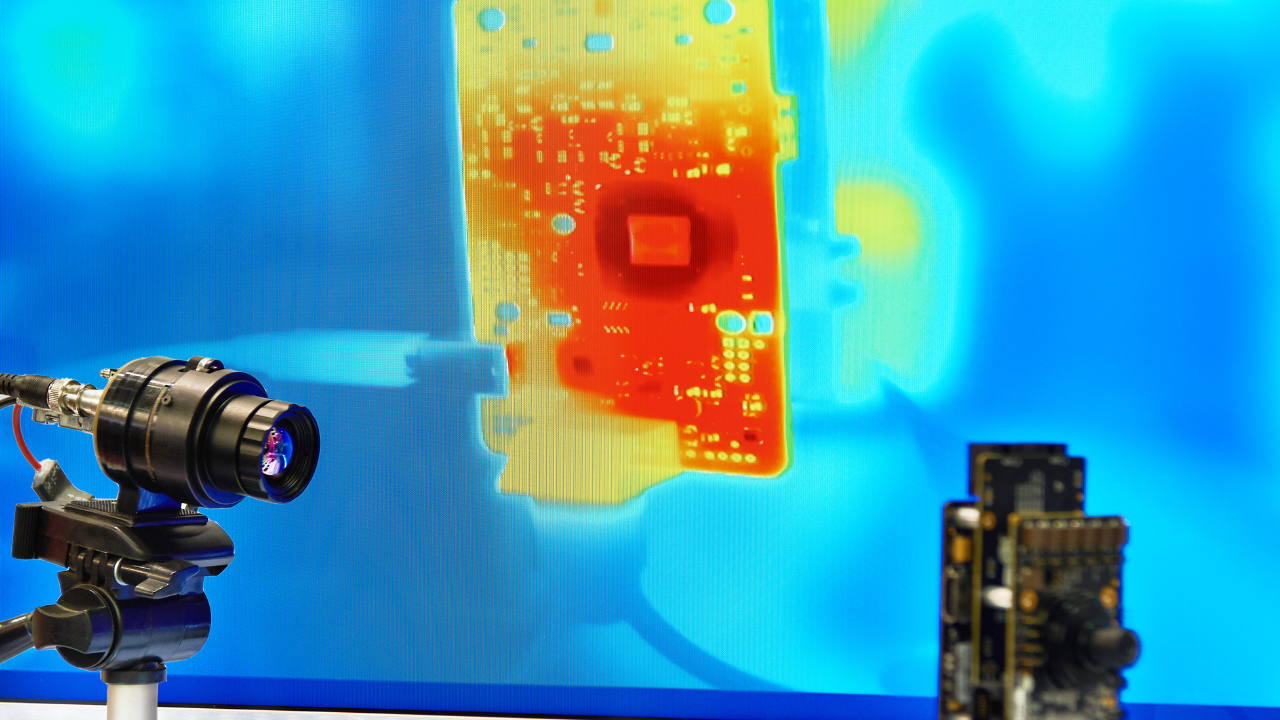

Non-destructive testing (NDT), a prime representation of CBM, allows for the inspection of equipment conditions without causing any damage or hampering operations. Techniques like ultrasonic testing, infrared thermography, or oil analysis can reveal anomalies invisible to the naked eye. Vibration analysis, for instance, is the most commonly used monitoring technique for rotating equipment, while the analysis of lubricants (oil analysis) can reveal the internal condition of a machine. Infrared cameras can also quickly detect temperature irregularities in energized equipment, and ultrasonic sensors can detect sounds produced by malfunctioning equipment.

Infrastructure for CBM

Implementing CBM requires a comprehensive network of interconnected devices and systems. The essential components of this infrastructure include:

Sensors: These are attached to assets to monitor performance metrics. They collect machine data and track indicators like vibration, temperature, current, pressure, and humidity to detect even small fluctuations and variations in performance.

Data Aggregation System: This system collects data from different sensors and offers a cloud-based condition monitoring platform for centralized data acquisition and analytics.

Data Analysis Software: This software analyzes the data for patterns and anomalies. It combines the efficiencies of cognitive and expert analysis with actionable insights across monitoring points.

CMMS Software: This is a centralized system that holds all the information and triggers maintenance actions. For instance, the Dynaway Mobile EAM offers increased efficiency and flexibility in your maintenance department by allowing maintenance workers to report status and progress on work orders in real-time.

Industries Suited for CBM

CBM is particularly beneficial in industries where equipment failure could lead to significant downtime costs, such as manufacturing, oil and gas, energy, and transportation. For instance, in the aviation industry, a minor malfunction can cause flight cancellations costing millions. CBM allows airlines to detect and address issues proactively, ensuring safety and efficiency.

To choose the most suitable condition monitoring solution for your needs, it’s important to understand your requirements, the capabilities and limitations of these solutions, and the specific characteristics of your industry and equipment.

Why CBM is a Valuable Inclusion in a Maintenance Strategy

Reduced Downtime of Assets that are Critical for Business Output

Condition Based Maintenance (CBM) has been proven to effectively reduce downtime in machinery and equipment by predicting and addressing potential issues before they become serious problems. The use of real-time monitoring systems like ATS’ Machine Health Monitoring can detect minute fluctuations in performance that could indicate an imminent failure. A study conducted by the Aberdeen Group found that companies utilizing CBM saw a 24% improvement in equipment uptime compared to those that did not use this approach. The predictive nature of CBM means that maintenance can be scheduled during non-peak times, thereby minimizing disruption to business operations and significantly reducing unexpected downtime.

Further research recently found that an offshore drilling company in the Johan Sverdrup field implemented a CBM system and reported a 70% reduction in unplanned downtime over a period of one year. This major reduction in downtime not only improved the company’s operational efficiency but also had a significant impact on the bottom line.

Extending Asset Lifecycle by Addressing Issues Early

CBM can significantly extend the lifespan of assets by identifying maintenance issues promptly. The real-time monitoring and reporting capabilities of tools like the Dynaway Mobile EAM client enable maintenance teams to address minor issues before they escalate into major problems that could compromise the lifespan of an asset. A study published in the Journal of Industrial Engineering and Management showed that the implementation of a CBM strategy resulted in a 20% extension of asset lifespan on average.

Moreover, a case study from the mining industry illustrates this benefit. A mining company implemented a CBM program and managed to extend the life of their heavy machinery by 25%. The early detection and resolution of maintenance issues played a key role in this outcome.

Significant Cost Savings

Maintenance costs can account for 10-25% of total operating costs in most industries, with labor constituting more than half of these costs. By enhancing maintenance efficiency and decreasing unplanned downtime, CBM can significantly reduce these costs.

A compelling example of the cost-saving potential of CBM comes from McKinsey and Company who studied the use of CBM in the aluminum rolling mill industry. By implementing a maintenance efficiency improvement process, one mill in the study was able to decrease its total maintenance costs by over 30%. Another case study from the wind energy sector revealed a wind farm that saved approximately $1.2 million per year after implementing a CBM strategy.

Increase in Safety Standards for Businesses with Machinery or Hazardous Assets

A noteworthy benefit of CBM is the enhancement of safety in the workplace. By identifying potential equipment failures before they occur, CBM minimizes the risk of accidents caused by machinery breakdowns. A study in the Journal of Loss Prevention in the Process Industries found that companies utilizing CBM had a 14% reduction in safety incidents related to equipment failure.

Reduction in the Businesses’ Environmental Footprint

Another significant advantage of CBM lies in its contribution to environmental sustainability. By optimizing the performance of machinery and equipment, CBM minimizes energy wastage and reduces the environmental footprint of operations. A study published in the International Journal of Production Economics revealed that companies implementing CBM saw a 9% reduction in energy usage. This not only contributes to cost savings but also helps companies meet their environmental and sustainability goals.

Is CBM Right for Your Business?

While CBM is a powerful tool, it is not a one-size-fits-all solution. Determining whether it suits your business requires an evaluation of the criticality of your assets, the implications of downtime, and the financial and human resources available for setup and ongoing management. A high-output manufacturing plant where efficiency directly impacts productivity and profitability could be an ideal candidate for CBM. Similarly, a hospital, where the reliability of medical devices is a matter of life and death, might also find CBM indispensable.

Instead, there are alternative methods such as proactive and preventive maintenance plans. As well as predictive maintenance, which uses a combination of both machine learning and artificial intelligence to accurately predict when equipment will fail.

CBM, despite its initial investment, is an attractive proposition for businesses looking to leverage technology for improved efficiency and cost-effectiveness. Like any strategic decision, the adoption of CBM requires careful evaluation of your business’s unique needs and resources. Done right, CBM could be your key to unlocking unprecedented operational excellence.

Charlie Green

Charlie Green is Senior Research Analyst at Comparesoft. Facilities Management, Smart Buildings, Workplace Management and Fixed Asset Management are his key research areas. Charlie holds a masters degree which allows him to offer data led and empirical research driven reports.

Related Articles

Principles of Insulation Testing

Top Tips for Selecting Pressure Measurement Transmitters

Gearbox Diagnostics Fault Detection

What is Vibration?

Why Record? Infrared Video

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera