Gear Pump Operation and Maintenance

PumpScout

Gear pumps are the most common type of positive displacement pump, ideal for transferring high viscosity fluids such as automotive oils, plastics, paint, adhesives, and soaps. They operate by creating suction at the inlet with a rotating assembly of two gears –a drive gear and an idler. Flow is determined by the size of the cavity (volume) between gear teeth, the amount of slippage (reverse flow), and the speed of rotation (rpm) of the gears.

As with any pump, proper operation and regular maintenance are vital to reducing costly pump repairs and maximizing pump efficiency. Below are helpful tips for operating your gear pump and ensuring it achieves a long operating life through regular maintenance.

Gear Pump Operation

– Operate close to the maximum rated speeds. Because gear pumps have poor volumetric efficiency at low speeds and low flow rates, they should be operated as close as possible to their maximum rated speeds for higher production and efficiency.

– Use special materials when pumping liquids with abrasives. A pump’s toothed gear construction allows particles to become trapped in small spaces, accelerating wear and reducing efficiency. If you need to transfer fluid containing abrasives, consider contacting the pump manufacturer to discuss hardened material options.

– Ensure that total life does not exceed 7.5 PSI. A gear pump cannot create a perfect vacuum, necessitating total lift (including pipe friction losses) to be one-half of the atmospheric pressure (approximately 7.5 PSI).

– Avoid low viscosity fluids. Gear pumps (especially internal gear pumps) are designed to handle high viscosity fluids to minimize slip. Pumping low viscosity fluids results in reduced flow rate and efficiency because it ‘slips’ through the tight spaces from the higher-pressure discharge side of the pump to the lower-pressure suction side of the pump.

– Do not run dry. Unlubricated gear teeth will rub together, creating friction and heat as the cogs expand and begin rubbing against the housing. This can destroy the pump, requiring costly repair and downtime.

Gear Pump Maintenance

– Keep maintenance records. One of the most important things you can do to ensure your pump operates smoothly is to keep a detailed record of baseline pump performance, regular maintenance, and any repairs. This will aid you in determining how the pump will operate in the future and the best way to either repair or replace specific parts.

– Check bearings regularly. The bearings are the most important area to maintain because they can cause imbalance if misplaced or defective. Check bearings regularly and replace as necessary by removing the defective bearing with a puller. Excessive noise can be an indication of bearing wear.

– Check gear pump clearance. A new gear pump has .007 to .005 inches of clearance from both the teeth and chamber of the gears. Periodically check for wearing of the teeth by attempting to pass a piece of paper between the clearances. If it passes between the clearances easily, it indicates that the bearings have been worn down and should be replaced.

By following regular maintenance schedules and adhering to proper operation procedures, gear pumps can be an efficient and productive solution to high-viscosity pumping needs.

PumpScout

Related Articles

There are occasions when you might want to permanently change the amount of fluid you are pumping, or change the discharge head of a centrifugal pump. There are four ways you could do this, of the four methods the middle two are the only sensible ones. In the following paragraphs we will learn what happens when we change either the pump speed or impeller diameter and as you would guess other characteristics of the pump are going to change along with speed or diameter.

There are occasions when you might want to permanently change the amount of fluid you are pumping, or change the discharge head of a centrifugal pump. There are four ways you could do this, of the four methods the middle two are the only sensible ones. In the following paragraphs we will learn what happens when we change either the pump speed or impeller diameter and as you would guess other characteristics of the pump are going to change along with speed or diameter.

See More

The previous article in this series, "Understanding Shaft Alignment: Thermal Growth," explained thermal growth and its affect on proper equipment alignment. A practical example involves a recent project at a wastewater treatment plant in Cleveland that needed realistic cold alignment targets for a 3600 rpm compressor to reach their accurate alignment targets.

The previous article in this series, "Understanding Shaft Alignment: Thermal Growth," explained thermal growth and its affect on proper equipment alignment. A practical example involves a recent project at a wastewater treatment plant in Cleveland that needed realistic cold alignment targets for a 3600 rpm compressor to reach their accurate alignment targets.

See More

Spindles are one of the most expensive and sophisticated rotating components on the planet. They rotate at super high speeds with fits and tolerances 10 to 20 times what is required on other rotating devices, such as pumps or motors. If there ever were machines that needed to communicate their health and activity it would be spindles.

Spindles are one of the most expensive and sophisticated rotating components on the planet. They rotate at super high speeds with fits and tolerances 10 to 20 times what is required on other rotating devices, such as pumps or motors. If there ever were machines that needed to communicate their health and activity it would be spindles.

See More

Is there is reason to suppose a properly repaired motor is less reliable than a new machine? This article will define reliability and repairability to help you answer this question.

Is there is reason to suppose a properly repaired motor is less reliable than a new machine? This article will define reliability and repairability to help you answer this question.

See More

The development of the electric motor has given us the most efficient and effective means to do work known to man. The electric motor is a simple device in principle. It converts electric energy into mechanical energy. Over the years, electric motors have changed substantially in design, however the basic principles have remained the same. In this section of the Action Guide we will discuss these basic motor principles. We will discuss the phenomena of magnetism, AC current and basic motor operation.

The development of the electric motor has given us the most efficient and effective means to do work known to man. The electric motor is a simple device in principle. It converts electric energy into mechanical energy. Over the years, electric motors have changed substantially in design, however the basic principles have remained the same. In this section of the Action Guide we will discuss these basic motor principles. We will discuss the phenomena of magnetism, AC current and basic motor operation.

See More

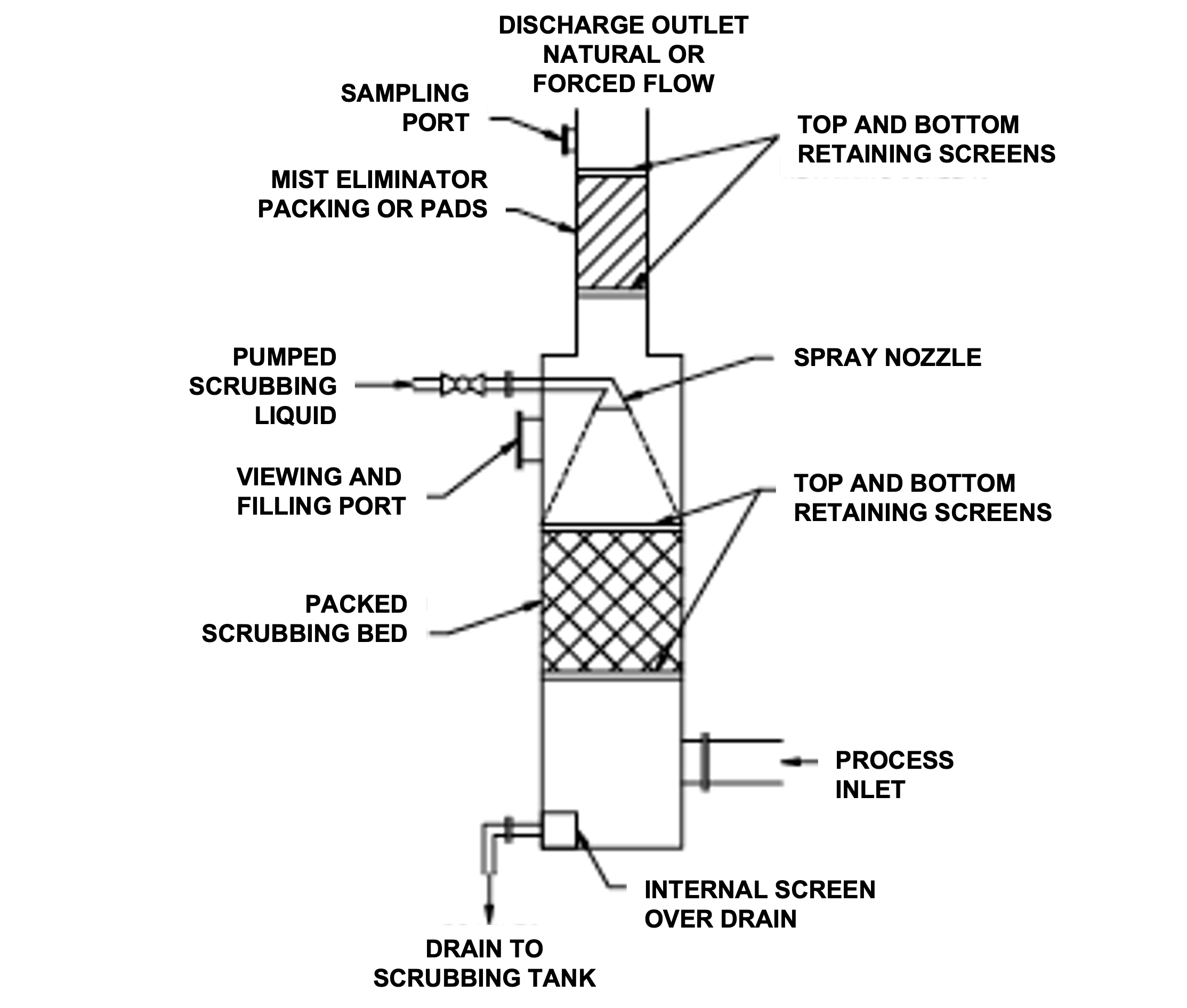

Is your scrubbing tower working? A wet scrubbing tower is used to clean odors, particles, mists, and vapors from a gas stream. The gas is forced through the tower. As it moves from inlet to outlet it is washed and cleaned. The washing is done with suitable chemicals that remove the active components in the gas flow. The gas is cleaned to environmentally acceptable levels and discharged to atmosphere.

Is your scrubbing tower working? A wet scrubbing tower is used to clean odors, particles, mists, and vapors from a gas stream. The gas is forced through the tower. As it moves from inlet to outlet it is washed and cleaned. The washing is done with suitable chemicals that remove the active components in the gas flow. The gas is cleaned to environmentally acceptable levels and discharged to atmosphere.

See More

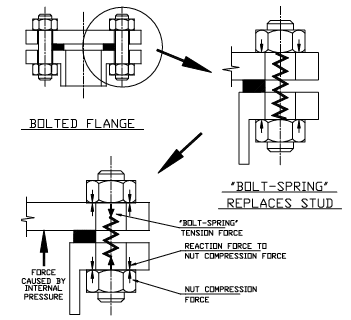

Prevent flange leaks with proper bolting practices. Bolts and gaskets behave like springs and unless flange bolts and nuts are properly tensioned the flange will leak. The correct tightening torque depends on bolt diameter, material of construction, process pressure and bolt fabrication.

Prevent flange leaks with proper bolting practices. Bolts and gaskets behave like springs and unless flange bolts and nuts are properly tensioned the flange will leak. The correct tightening torque depends on bolt diameter, material of construction, process pressure and bolt fabrication.

See More