Troubleshoot AC Motors

reliance.com

The following charts will give you multiple pathways to assist when you are attempting to troubleshoot AC Motors. The 4 problems covered are:

- Problem A – Motor won’t start or motor accelerates too slowly

- Problem B – Motor runs noisy

- Problem C – Motor overheats

- Problem D – Motor bearings run hot or noisy

#1 Troubleshoot AC Motors – Motor won’t start or motor accelerates too slowly

| A1: Check input power to starter. Is there power on all lines? (Three-phase motors won’t start on one-phase.) | Restore power on all lines | |

| A2: Check starter. Is overload protection device opened? | Replace or reset device. Does it open again when starting? | |

| A3: Is there power on all lines to motor? | Repair starter | |

| A4: Is voltage to motor more than 10% below nameplate voltage? | Restore proper voltage. | |

| A5: Check motor terminal connections. Are any loose or broken? | Repair connections. | |

| A6: May be wrong motor for application. Is starting load too high? | Install Design C or Design D motor. Install larger motor. | |

| A7: Is driven machine jammed or overloaded? | Remove jam or overload. | |

| A8: Are misalignments, bad bearings or damaged components causing excessive friction in driven machine or power transmission system? | Repair or replace component. | |

| A9: Are bad bearings, bent shaft, damaged end bells, rubbing fan or rotor or other problem causing excessive friction in the motor? | Repair or replace motor. | |

| A10: Check stator. Are any coils open, shored or grounded? | Repair coil or replace motor. | |

| A11: Check commutator. Are any bars or rings broken? | Replace rotor. |

#2 Troubleshoot AC Motors – Motor runs noisy

| B1: Are vibrations and noise from driven machine or power transmission system being transmitted to motor? | Locate source of noise and reduce. Isolate motor with belt drive or elastomeric coupling. | |

| B2: Is a hollow motor foundation acting as a sounding board? | Redesign mounting. Coat foundation underside with sound dampening material. | |

| B3: Check motor mounting. Is it loose? | Tighten. Be sure shaft is aligned. | |

| B4: Is motor mounting even and shaft properly aligned? | Shim feet for even mounting and align shaft. | |

| B5: Is fan hitting or rubbing on stationary part or is object caught in fan housing? | Repair damaged fan, end bell or part causing contact. Remove trash from fan housing. | |

| B6: Is air gap nonuniform or rotor rubbing on stator? | Recenter rotor rubbing on worn bearings or relocate pedestal bearings. | |

| B7: Listen to bearings. Are they noisy? | Lubricate bearings. If still noisy, replace. | |

| B8: Is voltage between phases (three-phase motors) unbalanced? | Balance voltages. | |

| B9: Is three-phase motor operating on one-phase? (Won’t start on single-phase.) | Restore power on three-phases. |

#3 Troubleshoot AC Motors – Motor overheats

| C1: Is ambient temperature too high? | Reduce ambient, increase ventilation or install larger motor. | |

| C2: Is motor too small for present operating conditions? | Install larger motor. | |

| C3: Is motor started too frequently? | Reduce starting cycle or use larger motor. | |

| C4: Check external frame. Is it covered with dirt which acts as insulation and prevents proper cooling? | Wipe, scrape or vacuum accumulated dirt from frame. | |

| C5: Feel output from air exhaust openings. Is flow light or inconsistent indicating poor ventilation? | Remove obstructions or dirt preventing free circulation of air flow. If needed, clean internal air passages. | |

| C6: Check input current while driving load. Is it excessive indicating an overload? | Go to Step C11. | |

| C7: Is the driven equipment overload? | Reduce load or install larger motor. | |

| C8: Are misalignments, bad bearings or damaged component causing excessive friction in driven machine or power transmission system? | Repair or replace bad components. | |

| C9: Are motor bearings dry? | Lubricate. Does motor still draw excessive current? | |

| C10: Are damaged end bells, rubbing fan, bent shaft or rubbing rotor causing excessive internal friction? | Repair or replace motor. | |

| C11: Are bad bearings causing excessive friction? | Determine cause of bad bearings (See Problem D). | |

| C12: Check phase voltage. Does it vary between phases? | Restore equal voltage on all phases. | |

| C13: Is voltage more than 10% above or 10% below nameplate? | Restore proper voltage or install motor built for the voltage. | |

| C14: Check stator. Are any coils grounded or shorted? | Repair coils or replace motor. |

#4 Troubleshoot AC Motors – Motor bearings run hot or noisy

| D1: Check loading. Is excessive side pressure, end loading or vibration overloading bearings? | Reduce overloading.* Install larger motor. | |

| D2: Is sleeve bearing motor mounted on a slant causing end thrust? | Mount horizontally* or install ball bearing motor. | |

| D3: Is bent or misaligned shaft overloading bearings? | Replace bent shaft or align shaft.* | |

| D4: Is loose or damaged end bell overloading shaft? | Tighten or replace end bell.* | |

| D5: Are bearings dry? | Lubricate.* | |

| D6: Is bearing lubricant dirty, contaminated or of wrong grade? | Clean bearings and lubricate with proper grade* | |

| D7: Remove end bells. Are bearings misaligned, worn or damaged? | Replace. | |

|

*Bearings may have been damaged. If motor still runs noisy or hot, replace bearings. |

Need more assistance troubleshooting you electric motor? Here are two great resources:

Maintenance and Troubleshooting of Electric Motors

Related Articles

How Can I Extend the Performance Range of Standard Cartridge Mechanical Seals?

In today's global environment, the "one size fits all" approach is used for so many products that we expect it to apply to just about everything. In the mechanical seal industry, one problem with that philosophy is the definition of the word all. Mechanical seals must live in literally every environment under the sun-from extreme hot to extreme cold, wet to dry, solid to gas, acidic to caustic and so on. Until relatively recently, a vast variety of cartridge mechanical seals were needed to accommodate these pump applications.

In today's global environment, the "one size fits all" approach is used for so many products that we expect it to apply to just about everything. In the mechanical seal industry, one problem with that philosophy is the definition of the word all. Mechanical seals must live in literally every environment under the sun-from extreme hot to extreme cold, wet to dry, solid to gas, acidic to caustic and so on. Until relatively recently, a vast variety of cartridge mechanical seals were needed to accommodate these pump applications.

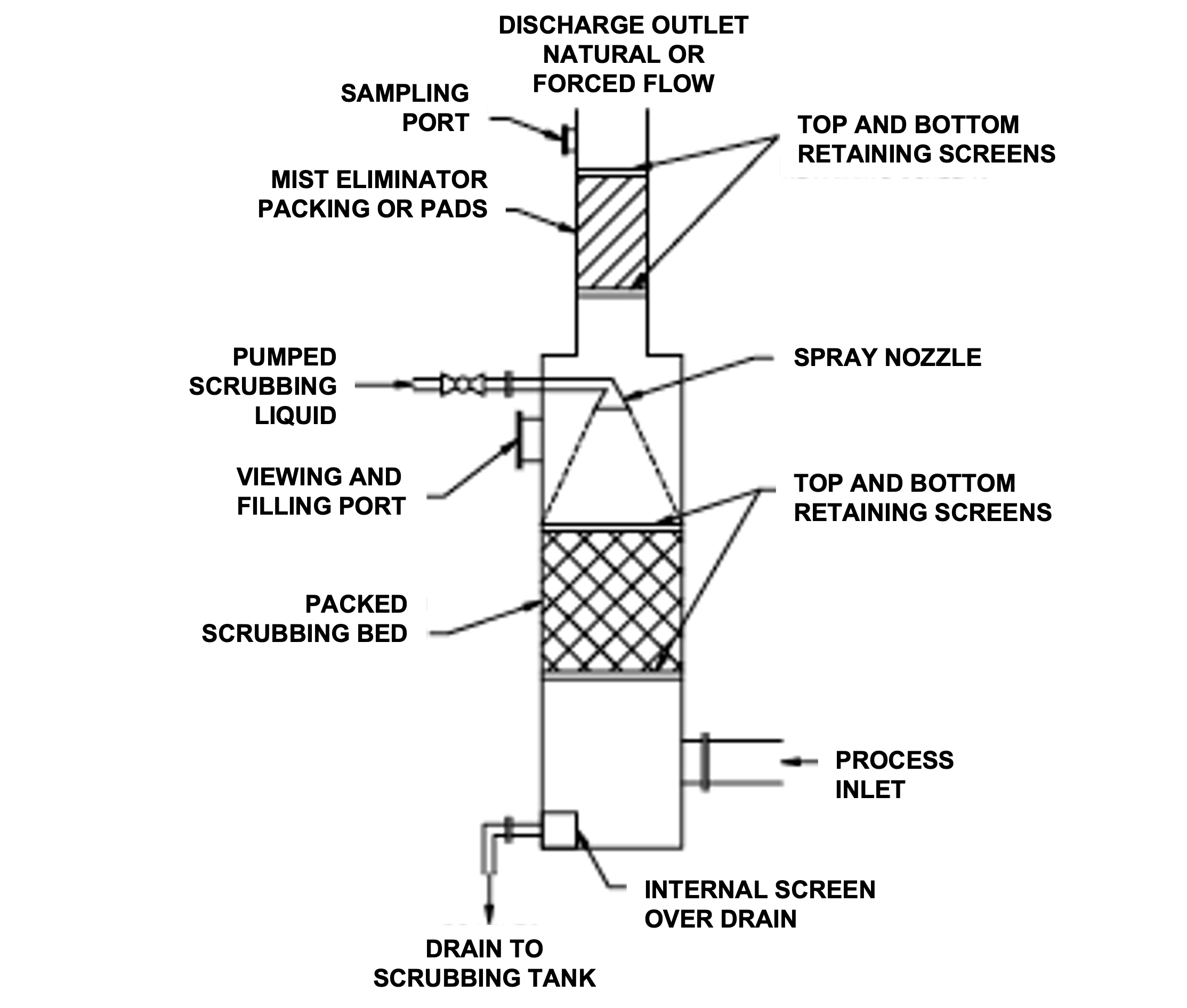

Is Your Wet Scrubbing Tower Working?

Is your scrubbing tower working? A wet scrubbing tower is used to clean odors, particles, mists, and vapors from a gas stream. The gas is forced through the tower. As it moves from inlet to outlet it is washed and cleaned. The washing is done with suitable chemicals that remove the active components in the gas flow. The gas is cleaned to environmentally acceptable levels and discharged to atmosphere.

Is your scrubbing tower working? A wet scrubbing tower is used to clean odors, particles, mists, and vapors from a gas stream. The gas is forced through the tower. As it moves from inlet to outlet it is washed and cleaned. The washing is done with suitable chemicals that remove the active components in the gas flow. The gas is cleaned to environmentally acceptable levels and discharged to atmosphere.

3 Keys to Improved Bolted Flange Joint Integrity

Every component of a bolted flange joint has a maximum allowable stress level. The mating flanges will begin to rotate or warp at a defined stress threshold. The studs or bolts of a given specification also will yield or be stressed past their elastic properties at a defined level. Non-metallic and semi-metallic gaskets will crush under excessive applied stress loads.

Every component of a bolted flange joint has a maximum allowable stress level. The mating flanges will begin to rotate or warp at a defined stress threshold. The studs or bolts of a given specification also will yield or be stressed past their elastic properties at a defined level. Non-metallic and semi-metallic gaskets will crush under excessive applied stress loads.

Comparing the Value of Single- and Double-Layer Insulation on Boiler Walls

My interest in writing this article was to explore one way to reduce the cost of manufacturing and installing new boilers: improved insulation practices within the boiler island. It is my opinion that the power industry requires a smarter and more economical insulation design on steam-generating boiler walls, especially when considering the rising cost and reduced availability of qualified field labor. Yes, the potential cost savings with improved insulation practices is small compared to the total plant cost, but every dollar saved is important.

My interest in writing this article was to explore one way to reduce the cost of manufacturing and installing new boilers: improved insulation practices within the boiler island. It is my opinion that the power industry requires a smarter and more economical insulation design on steam-generating boiler walls, especially when considering the rising cost and reduced availability of qualified field labor. Yes, the potential cost savings with improved insulation practices is small compared to the total plant cost, but every dollar saved is important.

Test for Pumping System Efficiency

A pump’s efficiency can degrade as much as 10% to 25% before it is replaced, according to a study of industrial facilities commissioned by the U.S. Department of Energy (DOE), and efficiencies of 50% to 60% or lower are quite common. However, because these inefficiencies are not readily apparent, opportunities to save energy by repairing or replacing components and optimizing systems are often overlooked.

A pump’s efficiency can degrade as much as 10% to 25% before it is replaced, according to a study of industrial facilities commissioned by the U.S. Department of Energy (DOE), and efficiencies of 50% to 60% or lower are quite common. However, because these inefficiencies are not readily apparent, opportunities to save energy by repairing or replacing components and optimizing systems are often overlooked.

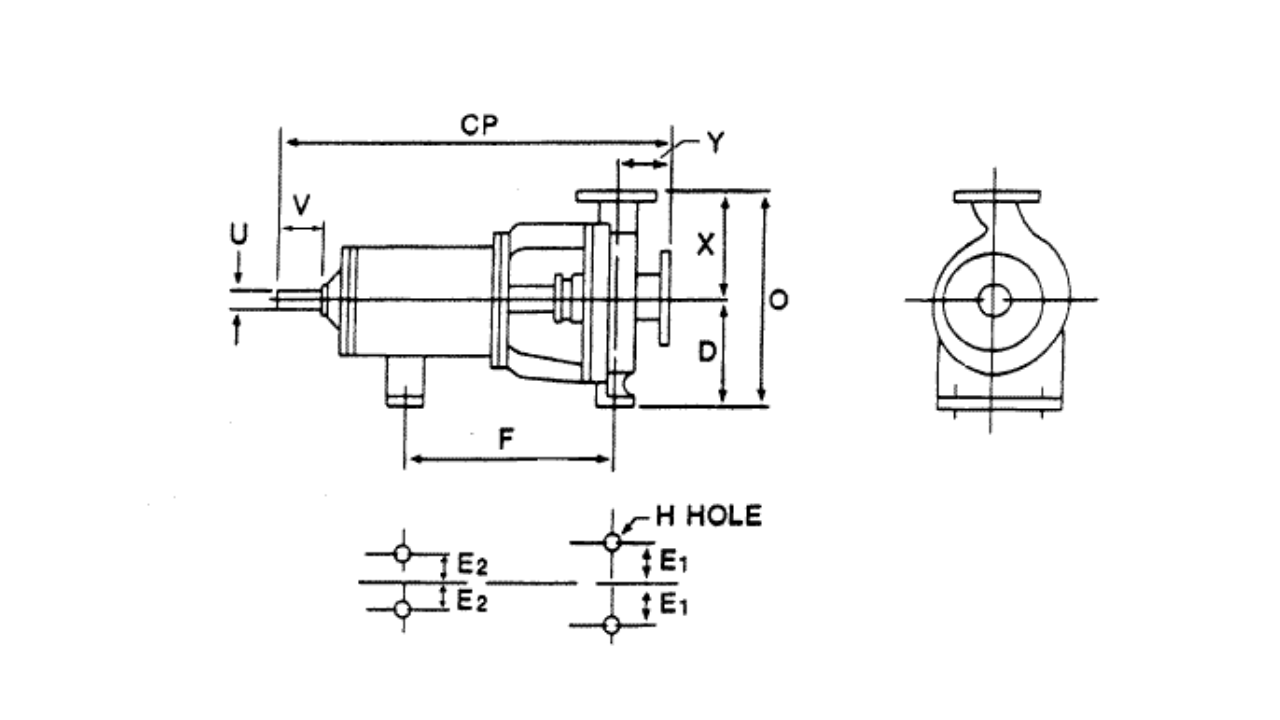

The ANSI Pump Standard 14-5

ANSI is an acronym used to describe the American National Institute Pump Standard. The standard evolved from the American Voluntary Standard (AVS) that was first proposed by the Manufacturing Chemists Association in the nineteen fifties. It is a set of inch dimensional standards that describe the envelope dimensions of a back pull out, centrifugal pump.

ANSI is an acronym used to describe the American National Institute Pump Standard. The standard evolved from the American Voluntary Standard (AVS) that was first proposed by the Manufacturing Chemists Association in the nineteen fifties. It is a set of inch dimensional standards that describe the envelope dimensions of a back pull out, centrifugal pump.

Factors which Influence the Speed of an Air Cylinder

It is very difficult to calculate and predict the speed of an air cylinder; there are too many variables which influence speed and on which it is difficult to gather accurate data. We must rely mainly on good design practices and use the benefit of past experience. It is better to have the cylinder speed too fast to begin with because it can always be reduced with a speed control valve, but if it is too slow to begin with, it is more difficult to increase its speed later.

It is very difficult to calculate and predict the speed of an air cylinder; there are too many variables which influence speed and on which it is difficult to gather accurate data. We must rely mainly on good design practices and use the benefit of past experience. It is better to have the cylinder speed too fast to begin with because it can always be reduced with a speed control valve, but if it is too slow to begin with, it is more difficult to increase its speed later.