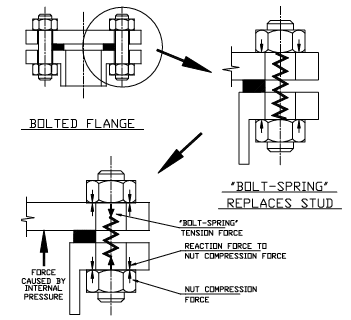

Prevent Flange Leaks with Proper Bolting Practices

Prevent flange leaks with proper bolting practices. Bolts and gaskets behave like springs and unless flange bolts and nuts are properly tensioned the flange will leak. The correct tightening torque depends on bolt diameter, material of construction, process pressure and bolt fabrication.