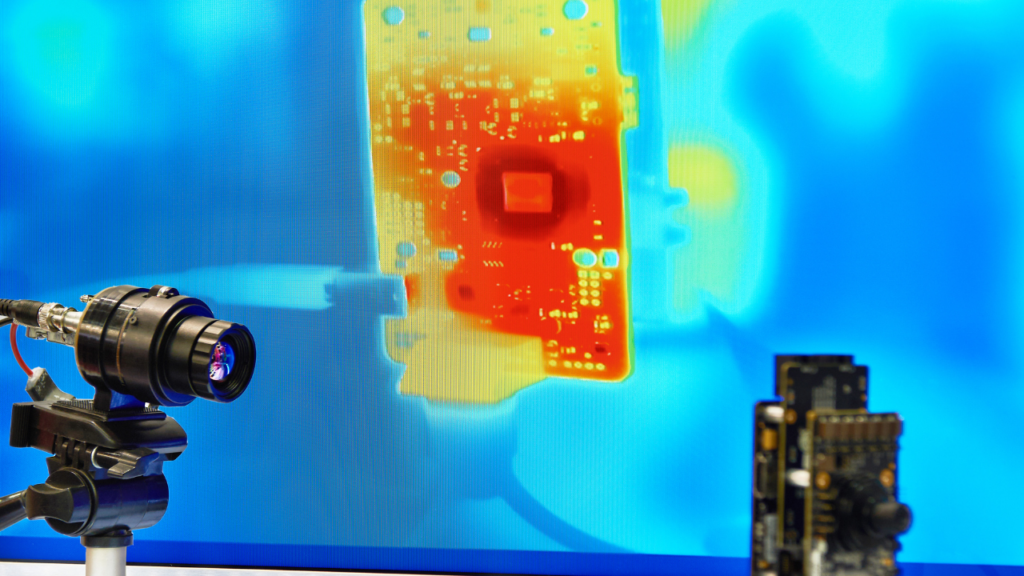

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera

During Academy of Infrared Training courses, we see many students who have purchased an infrared camera that is not suited for their intended use. These students have put their trust in a camera salesperson, and, many times, that salesperson was solely interested making a sale. Later, these students are disappointed to find out that the camera is not truly suited for their application. This article aims to help the camera buyer understand what basic camera specifications mean, and also help them determine what type of camera and options are suitable for their application. If you note your answers to questions throughout this article, by the end you should have a custom list of applicable specifications and options.