Asset Management Strategy: Detail Doesn’t Come from a Summary

Peter Morris, Founder and Managing Director, MCSPRO

Posted 11/2/23

Introduction

Several years ago, I was an asset management consultant working for an ERP software company. I was talking to a colleague about how we were setting up the asset management strategy and system and he said, “You can’t get detail from summary.” These words resonated and have stuck with me ever since.

As I’ve learned more over the years about implementing software, reliability, budgeting, root cause analysis, and pretty much everything to do with asset management, I’ve found that this simple statement becomes more and more important in everything we do.

I have been to operations where they raise a work order on each major asset and charge parts and labor to that work order for a year or so. I’ve seen systems set up with so little detail that it’s impossible to gather data at the granularity required to perform proper asset management.

On the other end of the scale, I’ve seen such a detailed asset hierarchy setup that it is obvious the consultants involved have never worked in a maintenance operation. What clearly should be parts or components are set up as assets, making it very difficult for maintenance to identify the correct asset. The result is that information is gathered at too high a level, creating summary information again. Right-sizing a system with logical coding that is well understood is vital to gathering detailed information within asset management systems. Budgeting is a prime example of why you must gather information at the detail level and why systems must be setup to facilitate the gathering of detailed records.

Requirements for a Well-Structured Asset Management Strategy

You can always summarize information, but what you can’t do is extract the necessary information you need if the information was gathered at a summary level.

Let’s talk about some requirements:

When setting up an asset management system, carefully review and configure available fields and records to support the following:

- Identify each asset appropriately in the structure. Avoid having too few or too many assets. A simple rule: if it requires history, consider it an asset.

- Establish a plant hierarchy that serves these purposes:

- First, it enables you to navigate to the right asset in a logical manner. Each asset should be found within about 6 or 7 levels in a hierarchy.

- Second, for the purpose of rolling up costs so you can see the cost of each maintainable asset.

- Lastly, assess criticality hierarchically. Plants are hierarchical in nature, and often the criticality of subcomponents follows the parent. Time can be saved setting up the system by defining criticality this way then adjusting the exceptions.

- Include proper development of maintenance tactics in the asset management strategy, preferably using a reliability methodology so you can identify the most likely ways an asset can fail then create tactics to address the ones you deem important according to your criticality assessment.

- Set up proper work order closure codes that mirror the failure modes by classes of equipment. If you try to use a generic set of failure codes, the possibilities become unwieldy, resulting in the workers completing work orders using incorrect codes. Ensure that the system is comprehensive but easy to use. Without this, you won’t have an effective root cause analysis system.

- Identification of identical equipment and parts is vital to having a system where information is not entered redundantly and can be reused. Enter information once, then reference again when needed.

- Set up work order templates for all preventive and predictive tasks. As the plant matures, create work order templates for corrective tasks. A planner should plan a job once, then reuse that preplanned job each time the task is done.

- Budgeting and cost control are impossible to manage without detailed information. A zero-based maintenance budget as part of an asset management strategy relies on:

- Accurate and detailed work order templates that can be run against a maintenance schedule simulation to produce a long-term prediction of when maintenance will be performed, including major component changeouts and shutdowns.

- Detailed work order history so budget lines can be created for corrective work. Only by including these items in budgets can you focus on them, understand their cost, and work towards reducing the most costly ones.

- KPIs. This one is pretty obvious. You don’t often know which KPIs you will need in the future, but if your asset management system has enough detail there is a fair chance you’ll be able to mine the information out of it to effectively monitor your performance and create future KPIs.

Effective Asset Management Strategy – Summary

In summary, the way your asset management system is set up and used, particularly the asset register, will play a major role in determining the ability of your maintenance organization to effectively operate. Data must be gathered at the appropriate level to allow it to be used, then summarized and reported on if necessary.

Peter Morris

Peter Morris is founder and managing director of MCSPRO a practice that focuses on SAP PM and MM as well as developing software solutions that increase productivity for maintenance practitioners.

Related Articles

Keys for Effective Troubleshooting

Analyzing Semiconductor Failure

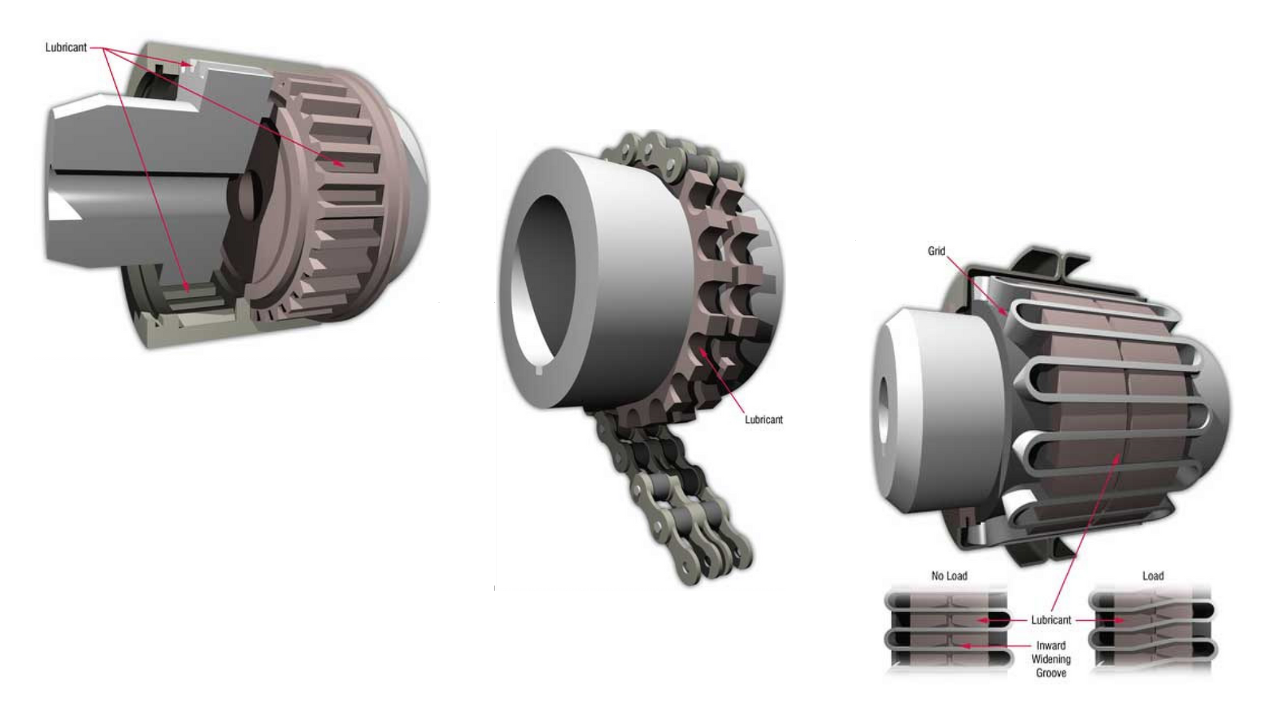

The Lubrication Requirements of Couplings

What is the True Downtime Cost (TDC)?

Improvement: What Comes First?

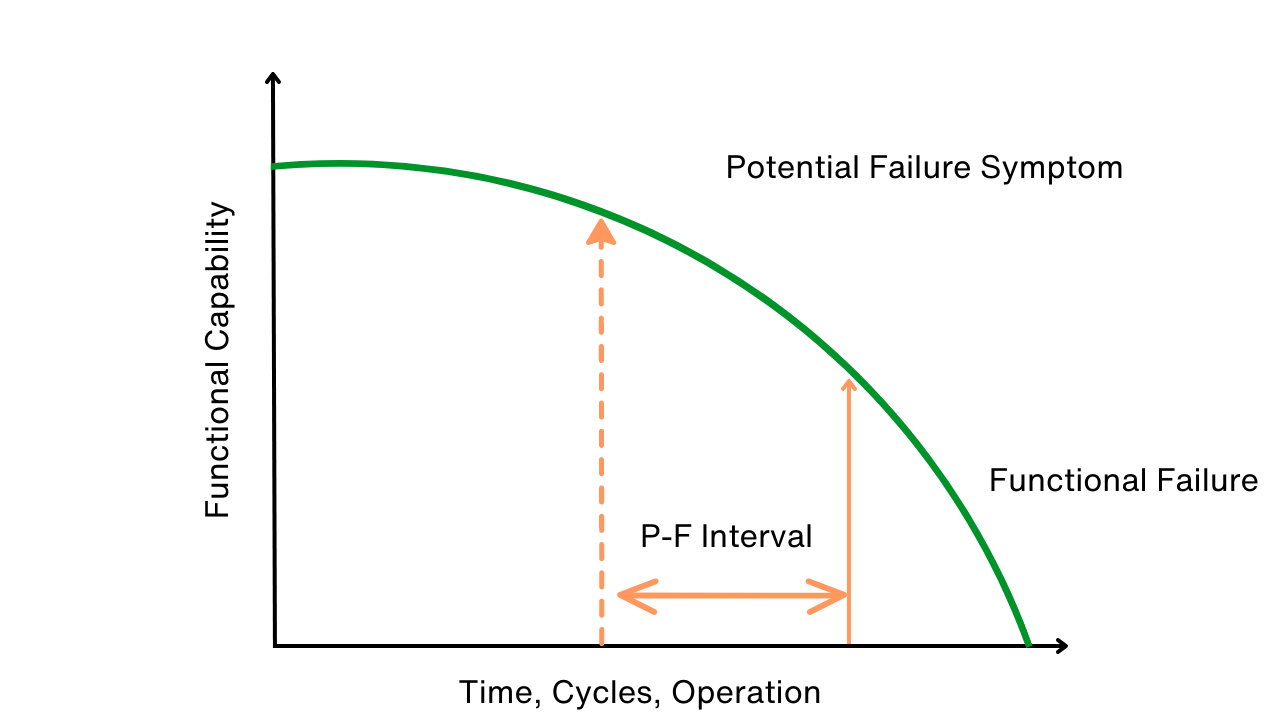

Use P-F Intervals to Map, Avert Failures