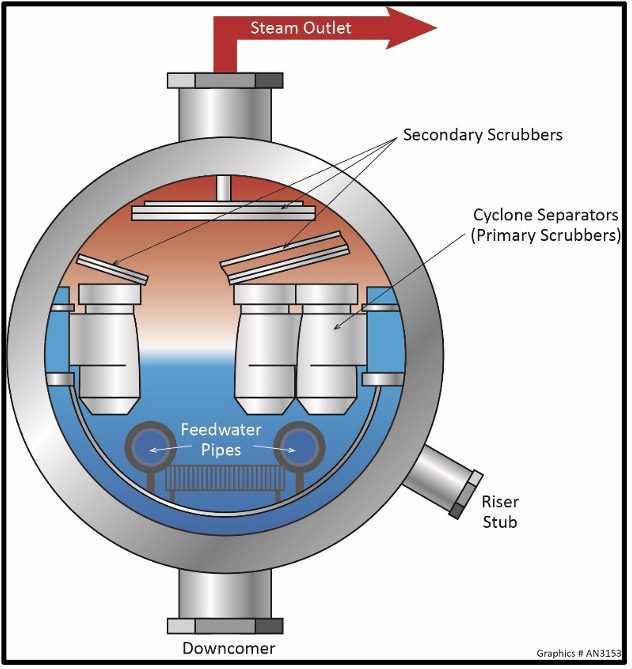

Optimizing Preventive Maintenance Activities

How do you determine the optimal frequency and scope of performing preventive maintenance tasks? This article presents several thoughtful ways to refine what is being performed on equipment and when. Be prepared to not think “one and done,” but rather a long-term iterative approach.

Optimizing Preventive Maintenance Activities Read More »