Ultrasound for Better Lubrication

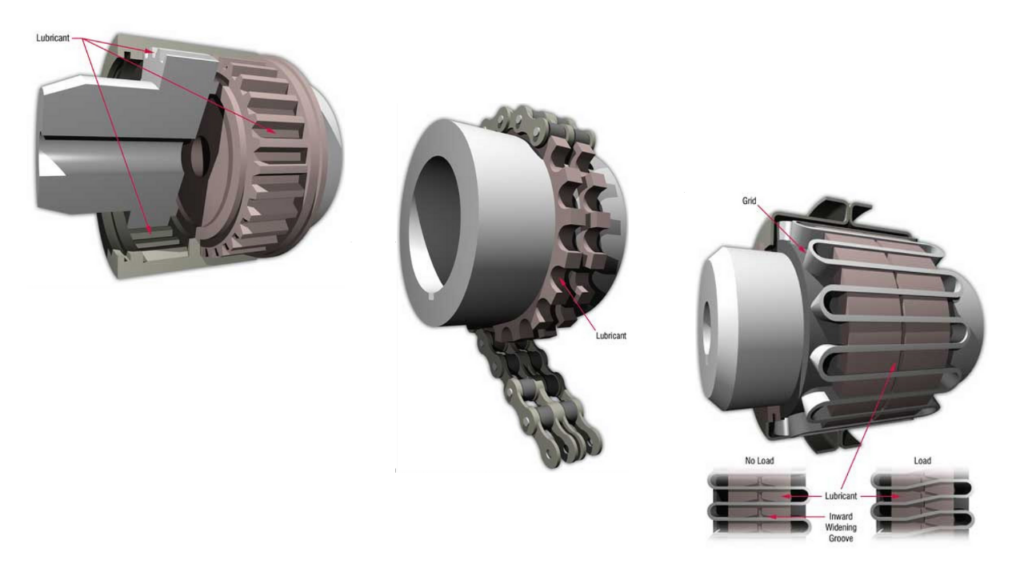

Ultrasonic technology (UT) has become widely accepted for the detection of leaks in both pressurized and nonpressurized systems. Most compressor service companies and several manufacturers own some type of ultrasonic sensor for pinpointing leaks. It is easy to cost-justify the purchase of an ultrasonic sensor based upon the high cost of energy loss due to leaks. However, there is another application for ultrasound that consumers, nondestructive testing (NDT) organizations, and even developers and manufacturers of ultrasonic sensors are often not aware of or overlook. UT can be used as a means to detect early wear of components such as bearings and gears due to lack of lubrication or overlubrication.