A CMMS for Employee Engagement

Reena Sommer, Ph.D. for Click Maint CMMS

Posted 1/13/26

Introduction

Two critical aspects of introducing a new technology into maintenance operations are the application’s soundness and employee engagement. When rolling out a Computerized Maintenance Management System (CMMS), considerable effort is devoted to finding the solution that best fits an organization. Yet, employee engagement is often underestimated or overlooked during this process. It is an interesting quandary since technicians, supervisors, and engineers are typically focused on equipment uptime, safety compliance, and reactive problem-solving. But without an engaged workforce, even the most advanced maintenance strategy can come up short. The result is that a disengaged team is more likely to experience higher turnover, inconsistent performance, and communication gaps—all of which ultimately affect operational reliability.cThat’s where identifying a CMMS for employee engagement becomes critical.

While CMMSs have traditionally been viewed as tools for tracking work orders, managing assets, and scheduling preventive maintenance, modern CMMS platforms have evolved well beyond those basic functions. They now serve as digital networks that connect people, processes, and data—creating transparency, accountability, and collaboration across teams. For this reason, selecting a CMMS for employee engagement is more critical than ever. When implemented thoughtfully, a CMMS designed to boost employee engagement can empower technicians with the tools they need to succeed and foster a culture of collaboration and pride.

The purpose of this article is to explore how a CMMS for employee engagement transforms maintenance operations from a purely technical function into a people-centered performance system. Here, we’ll demonstrate how the right CMMS features and practices not only streamline workflows but also inspire your maintenance staff, reduce stress, and strengthen your organization’s culture.

The Engagement Challenge in Maintenance Teams

Maintenance teams face unique engagement challenges. The work is often demanding, time-sensitive, reactive, and physically intensive, with extended hours and unpredictable schedules. When equipment fails, technicians are under pressure to fix issues quickly—often without complete information or adequate support. Over time, this constant crisis management can lead to frustration, fatigue, and disengagement. Employees may feel undervalued or disconnected from the larger organizational mission. They may view their roles as purely task-oriented rather than strategic. The result is high turnover, inconsistent performance, and diminished morale that ripple through the entire maintenance operation.

A CMMS can impact this cycle by addressing the root causes of disengagement. When properly implemented, the system replaces stress and chaos with order by streamlining work processes, clarifying responsibilities, and giving employees visibility into how their efforts impact the organization. Instead of reacting to problems, teams gain the tools to plan, prioritize, and take pride in preventive success. With real-time data, accessible asset histories, and transparent communication, a CMMS for employee engagement transforms maintenance work from a series of disconnected repairs into a cohesive, purpose-driven force—one where every technician understands their value and feels part of a high-performing team.

What Engagement-Focused Features a CMMS Should Offer

As a tool for engagement, a CMMS must go beyond basic maintenance tracking to enable communication, empowerment, and recognition. Therefore, having a centralized work order management and scheduling capability is one of the most essential features. When technicians can easily view upcoming tasks, prioritize workloads, and understand expectations, confusion and daily stress are reduced. A well-designed system helps employees see the bigger picture—how their specific tasks contribute to equipment uptime and operational goals.

Performance visibility is critical and enabled by CMMS dashboards, metrics, and feedback loops. By clearly displaying meaningful performance indicators—such as response times, work completion rates, and downtime reductions—the CMMS enables employees to visualize their direct contributions to maintenance operations. This shift helps technicians see their efforts reflected in measurable outcomes, moving them beyond the feeling of being unseen cogs in a system. Furthermore, managers can leverage this data to provide constructive feedback, recognize top performers, and celebrate milestones, which significantly boosts motivation and morale.

Employee engagement also flourishes when information flows freely. A CMMS that captures asset histories, standard operating procedures, and root-cause analyses become a living knowledge base that empowers every technician to learn and grow. Having shared access not only minimizes repeated mistakes but also strengthens collaboration across shifts and departments. In a similar vein, modern CMMS solutions often include onboarding and training integrations that encourage new hires to collaborate as they get up to speed quickly. By guiding them through digital workflows and maintenance practices, organizations can instill a team-oriented culture while reducing the steep learning curve. The result is a reduction in early burnout or disengagement.

Finally, today’s workforce expects technology that feels intuitive and mobile-friendly. A CMMS with mobile accessibility and a modern interface supports field technicians wherever they are—allowing them to log tasks, upload photos, and access information on the go. Having this type of access eliminates paperwork and empowers employees to make real-time decisions. When combined with safety modules, continuous improvement tracking, and optional gamification elements, these features become a dynamic platform for engagement, communication, and performance pride.

Practical Steps to Use Your CMMS to Boost Engagement

Transforming a CMMS into a tool for employee engagement starts with evaluating how it currently serves your team—not just your assets. While many organizations use their CMMS primarily for scheduling or tracking work orders, they often overlook its impact on morale, communication, and collaboration. To overcome this neglected issue, begin by auditing your current system through the lens of engagement. Consider the following:

- Is the interface intuitive?

- Do technicians feel confident using it?

- Does it make their jobs easier or more frustrating?

Also, involve employees in this process. When they have a say in how the system is used, they are more likely to feel ownership and commitment to its success.

Next, focus on configuring your CMMS to promote clarity and collaboration. Set up dashboards that highlight team achievements, not just equipment data. Create shared KPIs that reflect both individual and collective goals, such as reduced downtime, improved response times, or successful preventive maintenance compliance. Use the system’s communication tools—such as notes, comment fields, and integrated chat—to encourage real-time updates and knowledge sharing. When employees can see what their team members are working on, or when supervisors provide timely feedback within the system, the CMMS offers transparency rather than simply serving as a task-allocating vehicle.

Another powerful engagement strategy is to embed learning and growth opportunities directly into your CMMS workflows. For example, consider integrating short training videos or safety checklists into work orders to help technicians learn as they go. Beyond standardizing procedures, this approach also supports ongoing professional development. The CMMS can also serve as an onboarding tool, helping new employees feel confident and supported from the start. By linking maintenance data to training outcomes, leaders can identify skill gaps and design targeted learning plans.

To maintain engagement, recognition, and data-driven appreciation are essential. The CMMS can be used to create reports that identify outstanding performance, such as technicians who consistently close work orders on time, prevent repeat failures, or contribute innovative solutions. Successes can be recognized in team meetings or internal newsletters. Recognition can take many forms, but the key is consistency. When employees see that their work is being tracked and valued fairly, it builds trust and reinforces a culture of accountability.

Finally, measure engagement alongside operational metrics to ensure tangible progress. Pair system data—like work order completion rates or mean time to repair (MTTR) with softer metrics such as job satisfaction surveys or feedback sessions. Another approach is to monitor how often technicians log in to the system, how quickly they complete tasks, and how they perceive the CMMS in their daily work. Over time, these insights reveal not only how well the software supports operational goals but also how it contributes to employee engagement and retention.

Challenges and Mitigation

While a CMMS for employee engagement offers tremendous potential, it can also pose some challenges. First off, success depends on how it’s implemented and adopted. One of the most common challenges organizations faces is employees’ resistance to change, especially for maintenance professionals who have relied on paper-based systems or informal communication channels. For them, the introduction of new technology can initially feel disruptive. Without proper training and an explanation of why and how a CMMS is a technology worth learning, employees may view it as a monitoring tool rather than a support system. To move beyond this, leaders should involve technicians early in the implementation process. They should also clearly communicate the software’s benefits and provide continuous, hands-on training. When users feel heard and supported, not forced into compliance, they’re more likely to embrace the system enthusiastically.

Another common obstacle is poor configuration and data overload. A CMMS that’s overloaded with irrelevant data or poorly structured workflows can frustrate users and quickly degrade their engagement. The key is to prioritize simplicity and usability by tailoring dashboards, reports, and notifications to the team’s actual needs. To encourage engagement, it’s best to start small, focus on the most valuable metrics, and expand over time. Managers should remember that engagement isn’t driven solely by software, it’s the combination of technology, leadership, and culture. When a CMMS is viewed as a complement to broader engagement strategies, such as employee recognition programs, safety initiatives, and regular feedback loops, full engagement is more likely.

Finally, maintaining momentum is key. Once the novelty of a new system fades, engagement can dip if the CMMS isn’t continuously refined and aligned with evolving goals. To overcome this issue, it’s advisable to regularly review user feedback, track adoption rates, and update features to reflect how your team works. Celebrate milestones achieved through the system—such as reduced downtime or faster response times—to reinforce its value. By positioning a CMMS for employee engagement as an evolving part of your company’s culture rather than a static tool, organizations can sustain motivation, strengthen collaboration, and foster a workplace where technology and people grow together.

Conclusion

A CMMS designed and implemented with employee engagement in mind can redefine how maintenance teams work, communicate, and grow. When this happens, the software becomes more than just a tool for tracking assets and scheduling work —it becomes a CMMS for employee engagement, a platform that connects people to purpose. The CMMS will empower technicians with the clarity, recognition, and autonomy they need to take pride in their roles, while also giving leaders the insights to support and develop their teams. When employees feel their contributions are visible and valued, engagement naturally rises—powering better performance, higher retention, and a stronger safety and reliability culture.

The key takeaway here is that technology alone doesn’t create engagement, it’s how it’s used. Organizations that position their CMMS with human-centered strategies—such as transparent communication, recognition, and ongoing learning—will see the greatest return. By viewing your CMMS not only as an operational asset but as an engagement tool, you can cultivate a workplace where every technician feels connected, capable, and committed to shared success.

Reena Sommer

Reena Sommer has written extensively about CMMS and maintenance management best practices since 2018. Reena has been a contributor for Hippo CMMS, Click Maint among others. She has her Ph.D. in Psychology from the University of Manitoba. Reena hails from Winnipeg, Canada and currently resides in Chicago, Illinois, USA.

Related Articles

Talent Shortage Among Maintenance Professionals and How a CMMS Can Help

Fault Reporting: How to Improve Workflows in Maintenance Operations

The 8 Key Elements to Look for in Maintenance Software

Work Order Management: Structure and Organize Maintenance Processes

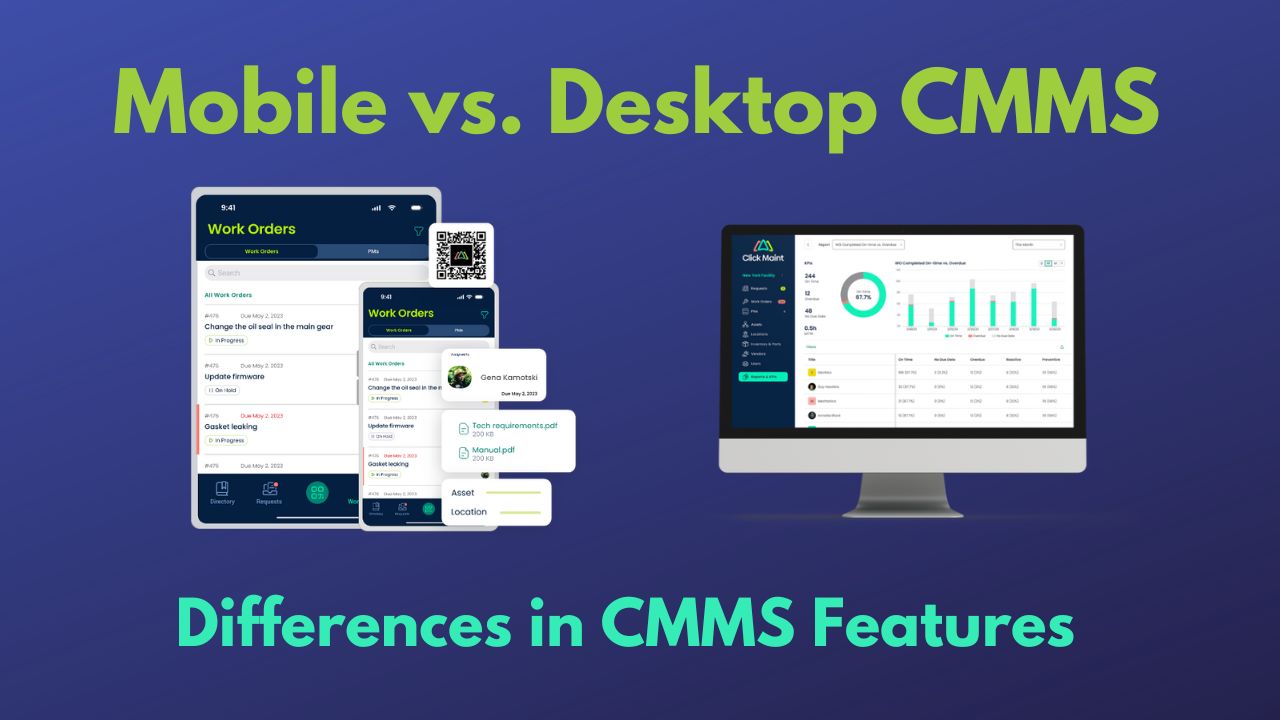

Mobile vs. Desktop: Differences in CMMS Features