Maintenance Workforce Development: Adapting to Industry Shifts

Reena Sommer, Ph.D. for Click Maint CMMS

Posted 3/20/2025

Future-Proofing Maintenance Operations

As the maintenance talent shortage challenges industries, companies must adopt long-term strategies to ensure operational stability and efficiency. Future-proofing maintenance operations require a combination of technology adoption, maintenance workforce development, and industry collaboration. A CMMS is essential in automating tasks, optimizing workforce productivity, and enabling data-driven decision-making. Below are several strategies that organizations can implement to build a sustainable maintenance workforce.

Read Part 1: Talent Shortage Among Maintenance Professionals and How a CMMS Can Help

Adopting New Technologies to Supplement Workforce Limitations

IoT (Internet of Things), AI-driven analytics, and automation play a role in the rapid advancement of maintenance technology by transforming how maintenance teams operate. These technologies help offset the talent shortage by reducing manual workload, improving equipment reliability, and enabling predictive maintenance strategies. A CMMS can help with:

- Integration with IoT and Smart Sensors: A CMMS can connect with IoT-enabled equipment to collect real-time data, detect performance anomalies, and trigger automated maintenance alerts. This reduces reliance on manual inspections.

- AI-Driven Predictive Maintenance: Advanced CMMS platforms use AI and machine learning to analyze maintenance data and predict failures before they occur. These valuable technologies minimize downtime and allow teams to focus on strategic repairs.

- Automated Workflows and Task Assignments: A key feature of a CMMS is its ability to automatically generate work orders, assign tasks based on technician availability, and prioritize critical issues. Automated work orders reduce administrative workload and improve operational efficiency.

Building Partnerships with Industry Associations and Educational Institutions

We have already learned that one of the biggest challenges in addressing the maintenance talent shortage is the lack of skilled workers entering the industry. One way to address this issue is by forming partnerships with technical schools, trade programs, and industry associations. This is another way for companies to create a pipeline of new talent. A CMMS can help with:

- Monitoring Apprenticeship Programs: A CMMS can help track apprentice progress, manage on-the-job training schedules, and document completed tasks for certification purposes.

- Standardized Training Documentation: Companies can use a CMMS to create digital training manuals, best practice guides, and safety protocols, making it easier to onboard and train new hires. These steps reduce confusion and frustration while instilling confidence and motivation in new apprentices.

- Collaboration with Trade Schools: Some CMMS platforms facilitate simulation-based training, where students can manage maintenance tasks in a virtual digital environment before entering the workforce.

Encouraging Continuous Learning and Workforce Adaptation

The future of maintenance requires a workforce that can continuously adapt to technological advancements. Companies that invest in ongoing education and skills development will have an edge in maintaining operational efficiency. A CMMS can help with:

- On-Demand Training Modules: Some CMMS platforms offer built-in e-learning tools that allow technicians to update their skills wherever they are.

- Job Rotation and Cross-Training: CMMS data can help identify team skill gaps, enabling managers to rotate employees into different roles for cross-training opportunities.

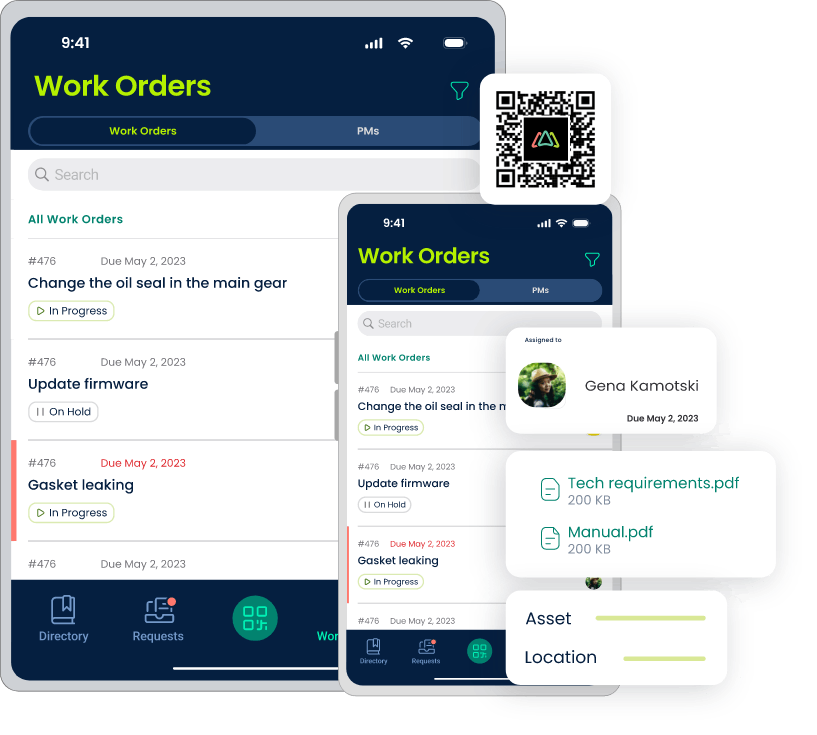

Leveraging Remote Maintenance and Mobile CMMS Access

Due to a shrinking workforce, organizations need flexible solutions that allow maintenance teams to operate efficiently, even with limited personnel. Mobile CMMS and remote maintenance capabilities are central to ensuring continuity in operations. A CMMS can help with:

- Remote Work Order Management: A mobile CMMS lets technicians receive, update, and close work orders from any location. This feature improves response times and reduces unnecessary reliance on a facility-based computer.

- Live Video Support for Troubleshooting: Some CMMS platforms integrate with video conferencing tools, enabling remote experts to guide technicians through complex repairs from wherever they are located.

- Cloud-Based Access to Maintenance Records: A cloud-based CMMS ensures that all maintenance data is available anytime, anywhere. This allows teams to collaborate more effectively across multiple locations.

Reducing Maintenance Costs and Increasing Asset Longevity

Another looming talent shortage concern is maintaining operational efficiency without increasing costs. CMMS solutions help organizations extend equipment life, reduce downtime, and optimize resource allocation. A CMMS can help with:

- Automating Preventive Maintenance (PM) Schedules: A CMMS ensures that maintenance tasks are performed at the right time, preventing costly breakdowns and unplanned repairs.

- Optimizing Spare Parts Inventory: CMMS tracks inventory levels and automatically reorders critical spare parts. This feature prevents delays that can arise from stock shortages.

- Extending Asset Lifespan: CMMS helps organizations effect maintenance strategies that maximize asset longevity by tracking equipment performance and identifying wear and tear trends.

Conclusion – Maintenance Workforce Development

The maintenance talent shortage is an ongoing challenge for many company stakeholders and maintenance managers. The gap in available talent impacts equipment uptime, operational costs, and safety compliance. However, when organizations embrace technology-driven solutions like CMMS, these changes can be mitigated by automating workflows, optimizing technician productivity, and preserving institutional knowledge.

To stay ahead, maintenance managers must assess their current processes and identify areas for automation. Company stakeholders should view CMMS adoption as a long-term investment in operational stability. Now is the time to modernize and explore CMMS solutions and future-proof maintenance operations.

Reena Sommer

Reena Sommer has written extensively about CMMS and maintenance management best practices since 2018. Reena has been a contributor for Hippo CMMS, Click Maint among others. She has her Ph.D. in Psychology from the University of Manitoba. Reena hails from Winnipeg, Canada and currently resides in Chicago, Illinois, USA.

Related Articles

Too Small for a CMMS? Think Again

The Role of Information Technology in Plant Reliability

The Future of CMMS