Chemical Corrosion Control

Mike Sondalini, PWW EAM System Consultant

with permission of BIN95 Business Industrial Network

Posted 3/13/2025

Chemical corrosion control. Chemical corrosion can destroy the containment materials in contact with a process. Means exist to mitigate and even prevent chemical corrosion.

ACCEPTABLE CORROSION

At times chemical corrosion is acceptable and one need only allow for it by using thicker materials.

An example is the storage of sulphuric acid in mild steel tanks at ambient conditions and concentrations higher than 80%. Though the acid attacks the metal, the rate of corrosion is extremely slow. Using thick-walled steel tanks with a corrosion allowance which takes decades to thin can be a cost-effective option.

Sulphuric acid absorbs moisture from the air. If the top layer in a mild steel tank is left undisturbed it will dilute and attack the steel. A 12mm steel plate can corrode through in 12 months. Circulating the acid weekly if it is stored in carbon steel tanks. For small quantities of sulphuric acid, a suitable plastic tank can solve the storage and corrosion problem cheaply.

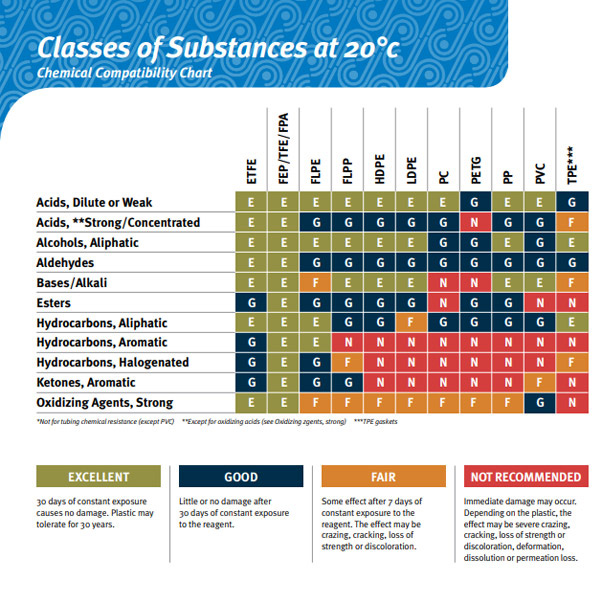

SELECT RESISTANT MATERIALS

Using more resistant materials will reduce the effect of chemical attack. Specialist metals and nonmetals to contain aggressive environments are available. These can be expensive, and their use is based on their cost effectiveness.

In particular, select low corrosion rate metals for diaphragms used in process instrumentation. It is false economy to select a 316 stainless steel diaphragm for a pressure transmitter on a tank of 98% sulphuric acid. Though corrosion tables indicate 316 stainless has a low corrosion rate, experience shows that after two years of service the diaphragm can fail by pin holing. For an additional 20% cost a Hastalloy C diaphragm provides a corrosion life 10 times longer.

COMPATIBLE COATINGS AND LININGS

Prevent chemical attack by coating in a material unaffected by the chemical. Rubber lining of hydrochloric acid storage tanks and plastic lining of process piping are examples. Teflon coating can protect a stainless steel sparge feeding sulphuric acid into a mixing vessel.

Rubber linings normally fail at joins. Check the correct procedure is used when they are mounted in place. Always test the coating to prove there are no holes. High voltage spark testing is used on thick coatings and linings while the low voltage ‘wet sponge’ method is used on thin coatings.

CHANGED MATERIAL PROPERTIES

Heat from welding processes alters the metal properties at the heat-affected zone (HAZ) of the weld. Stresses are introduced into the metal and grain microstructures are altered.

Consideration of the welding method, weld procedure and use of stress relief can mitigate the effects. The effect of welding is particularly evident when hot caustic solutions are contained in mild steel vessels. Unless stress relieved, chemical attack can occur at the HAZ of the welds.

CONSIDER PROCESS CONDITIONS

Using corrosion tables without considering all the process conditions can lead to poor materials selection. Most published data on compatibility do not take into effect agitated conditions. Some data only applies to ambient temperatures. Data is normally not available on the effect of aeration. Nor is data readily available on the effect of other contaminants, for example chlorides with stainless steels.

In uncertain or changeable situations will occur in a vessel consult the material manufacturer and ask for their advice. If they cannot help, then the only remaining option is to conduct your own laboratory tests or field trials.

Mike Sondalini

Mike Sondalini is a Senior Consultant at PWWEAM System-of-Reliability. BEng(Hons), MBA, CPEng. As a consultant and trainer, Mike was able to present his insights to his clients, suggesting innovative approaches to plant and equipment reliability. Their feedback was resoundingly positive. Efforts which earned him an international reputation for articulate, out-of-the-box articles on plant and equipment reliability, life-cycle EAM, maintenance management, work quality assurance, and team building. After decades of dedicated research, Mike authored “Industrial Manufacturing Wellness: The Complete Guide to Successful Enterprise Asset Management” a revolutionary approach on how maintenance and physical asset management systems should be run, the book detailed who, what, where, when, why, and how outstanding reliability could be achieved. Each step based in scientific and mathematical understanding to ensure repeatability of results and optimal outcomes.

Related Articles

Proactive Maintenance for Hydraulic Cylinders