Preventing Failures and Extending Equipment Life: The Key to Increasing Uptime

Elizabeth Ruiz

Posted 12/6/2023

What is the foundation to increased uptime? Preventing failures and extending equipment life. It is essential to define best practices for leadership to clearly communicate the organization’s direction for reliability improvements. Are you implementing the following best practices in your plant?

Check 1: Life Cycle Cost (LCC)

Equipment life cycle starts with specification, design, and engineering of equipment and production systems. Instead of simply focusing on the cost of purchasing equipment, specify, design, and buy assets based on LCC.

Establish a good LCC process by creating a close partnership among operations, maintenance, and engineering. They will be working together in the early stages of new installations so the relationship must be collaborative.

An efficient LCC process results in:

- Reliable equipment designs that are easy to maintain.

- Equipment that can be easily monitored for condition.

Technical examples of a good LCC process include:

- Avoiding turbulence and cavitation by using 10x the diameter of straight pipe to the inlet of single-ended centrifugal pumps.

- Using hinges on tank entry ports for fast and safe entry vs. traditional tank entries that require lifting devices that take two people to open.

- Having as few bolts as possible on tank entry ports to reduce wrench time.

- Installing oil sampling ports on all pertinent oil reservoirs.

- Marking operating ranges on gauges to quickly check the reading.

- Installing jacking bolts (push bolts) on motors and gearboxes for accurate alignment.

In many plants it is obvious that there is a weak partnership among operations, maintenance, and engineering. Often, the root of the problem is engineers being rewarded for completing projects on time and under budget – greatly decreasing the incentive to consider LCC.

Check 2: Alignment

Most organizations have established a basic requirement for good alignment, along with tools and training. But is it safe to assume alignment is done properly just because the basics are in place?

Some plants struggle with allotting time to do good alignment, some don’t have the correct design and/or don’t maintain bases and foundations which is necessary to perform alignment well. Sometimes standards such as heat checking and avoidance of pipe strain are neglected.

Estimate the alignment in your plant with a Gemba walk checking for:

- Poor foundations

- Equipment without jacking bolts

- Motors with beat marks from sledgehammers

- Shim packs larger than four

- Bolt-bound equipment/undercut bolts

- Hot bearings

Check 3: Reliable Operating Practices

Good operating practices are vital to the preventive maintenance process. Good practices prevent failures; poor practices encourage them. Ask your maintenance team these questions:

Preventing Failures and Extending Equipment Life with SOPs

It is common to see Standard Operating Procedures (SOPs) in organizations, but do they include equipment reliability issues? Here are some examples of common problems that could occur in many plants:

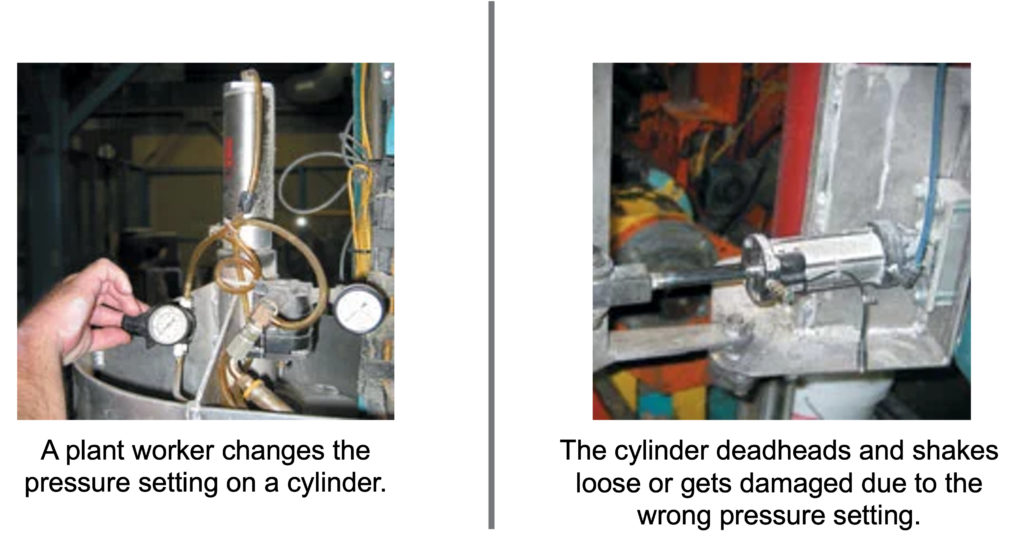

1. Pneumatic cylinder: When operators feel the pressure for increased production, it can be easy to make mistakes in service of higher volume. Say operators increased the pressure setting on a pneumatic cylinder to as much as 100% to get the equipment to run faster. Because this exceeds twice its designated speed, it will deadhead and the rod will be shaken loose and/or bent. In turn, maintenance would come around and change the pressure setting during weekly PM in the area. Air pressure settings must be a part of operator training and there must be SOPs for the equipment provided.

2. Motor start-up: On start-up, the current surge through an AC motor is usually 4 – 7 times the 100% load. If the start button is pushed repeatedly in a short period of time, it is common for the motor windings to burn or be otherwise damaged. Make sure operators know this and operate equipment accordingly.

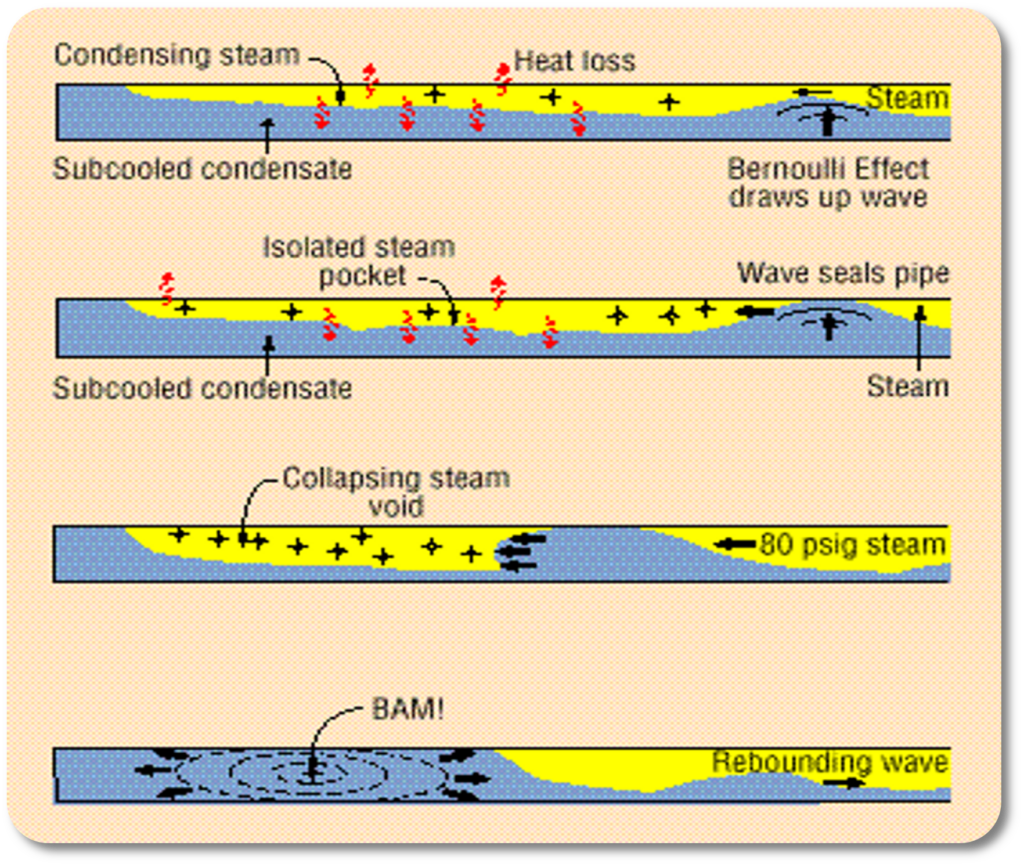

3. Steam systems: An operating procedure as simple as opening a valve too quickly can have severe consequences for a piping system. This phenomenon, a common problem in many industries, is called water hammer (see illustration).

Water hammer:

- Steam enters a cold piping system and condenses into water.

- The water travels with great speed and causes damage to pipes and flanges as it travels through the system.

- Piping elbows are especially vulnerable to water hammer.

Open communication among operations, maintenance, and engineering is key during the design and selection phase of equipment. The teamwork and communication must continue after installation for good reliability. It can be beneficial to have operations and maintenance do joint inspection routes and PM tasks at least once a week; they should also report findings to supervision as a team.

Preventing Failures and Extending Equipment Life: Summary

The foundation for increased uptime lies in the proactive measures of preventing failures and extending equipment life. Implementing key best practices such as prioritizing Life Cycle Cost (LCC) considerations in equipment specification, design, and installation, ensuring proper alignment through regular checks, and fostering reliable operating practices, including the incorporation of equipment-specific Standard Operating Procedures (SOPs), are critical steps.

The collaboration of operations, maintenance, and engineering is necessary throughout the equipment lifecycle, from collaborative partnerships in the early stages to joint inspection routes and preventive maintenance tasks. By adhering to these practices, your plant can enhance equipment reliability, minimize downtime, and increase production.

Midweek with Maintenance World

Looking for a midweek break? Keep up with the latest news brought to you by the Maintenance World Crew.

Related Articles

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

South Carolina Ranked as the #1 State for Manufacturing

The Decade of American Reshoring

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

HBD Condition Monitoring Devices at the center of Ohio Derailment

Failure Analysis Uncovers the Cause of the Keystone Oil Spill