The Fight to Repair Industrial Electronics

Willian Santos, ABI Electronics

Posted 07/27/2023

Willian Santos is the International Sales Manager at ABI Electronics – Manufacturer of Test, Repair & Reverse Engineering Equipment. He had the opportunity to share the mission of “Repair, Don’t Waste” with Interesting Engineering. “Repair, Don’t Waste” is a movement fighting to reduce e-waste and encourage the repair of industrial electronics. Santos explains why time is up for the break-and-replace mentality, and how the world needs to change to usher in a new era of sustainability in industry.

Industrial electronics can cost anywhere from a few hundred to over $10,000 per circuit board, depending on its complexity and components required. This is a far cry from our everyday electronics, for which repair is often not considered as it is not economically viable. Whereas if an industrial circuit board undergoes troubleshooting and the problem is found to be a tiny component worth pennies, this can be replaced and the board is restored to full working order for a fraction of the cost of a new board.

Unsurprisingly, obsolescence in industry compounds the problem of replacing circuit boards further.

“The (OEMs) are making a conscious decision of building a technology with what’s known as programmed obsolescence…by making design decisions that will make that piece of technology obsolete within two to three years rather than five, ten, fifteen, twenty years.”

Willian Santos, ABI Electronics

Obsolescence is an increasingly publicized issue within the industrial sector – companies turn to their OEMs for support and services to keep their critical systems functioning and are turned away, in some cases even actively discouraged from repair by the manufacturers. This practice is entirely wasteful and unsustainable – at Repair, Don’t Waste we hope to liberate companies from the will of OEM’s and empower them to carry out their own repair and maintenance on vital assets.

However, this new age of troubleshooting and internal repair labs cannot prevail without repair engineers and technicians – professionals who are extremely hard to source.

“We need to put pressure on education to make sure that we are training the next generation of repair heroes, the people who are going to be helping us get to those net zero targets by coming out of the university and colleges fully trained and equipped to repair, not replace.”

Willian Santos, ABI Electronics

Educational institutions have a huge part to play in making a sustainable future a reality. The wider focus of society needs to shift – although innovation has a part to play, it is the old methods of maintaining and repairing vital systems that will ensure the reduction of E-waste and the longevity of natural resources.

Credit to Mike Brown from Interesting Engineering for hosting this podcast. Lexicon by Interesting Engineering is a series that dives into the how and why of latest advancements, aiming to comprehend how the future is coming together today.

Willian Santos is the International Sales Manager at ABI Electronics — Manufacturers of Diagnostic & Reverse Engineering Systems for Sustainment & Repair of Critical Electronics. Santos worked with ‘Repair, don’t waste’ — Created in 2015 by ABI Electronics in the UK, the ‘Repair, don’t waste’ movement seeks to draw the attention of business leaders, academia, and the wider society to the benefits of developing the capabilities to repair rather than replace industrial electronic systems. ‘Repair, don’t waste’ aims to facilitate access to relevant technology and training for repair, share knowledge, and best practices implemented by leading organisations that are reducing waste, costs and creating quality technical jobs across the world.

Related Articles

Bearing Repair: An Alternative to Replacement

Is a Repaired Motor Less Reliable?

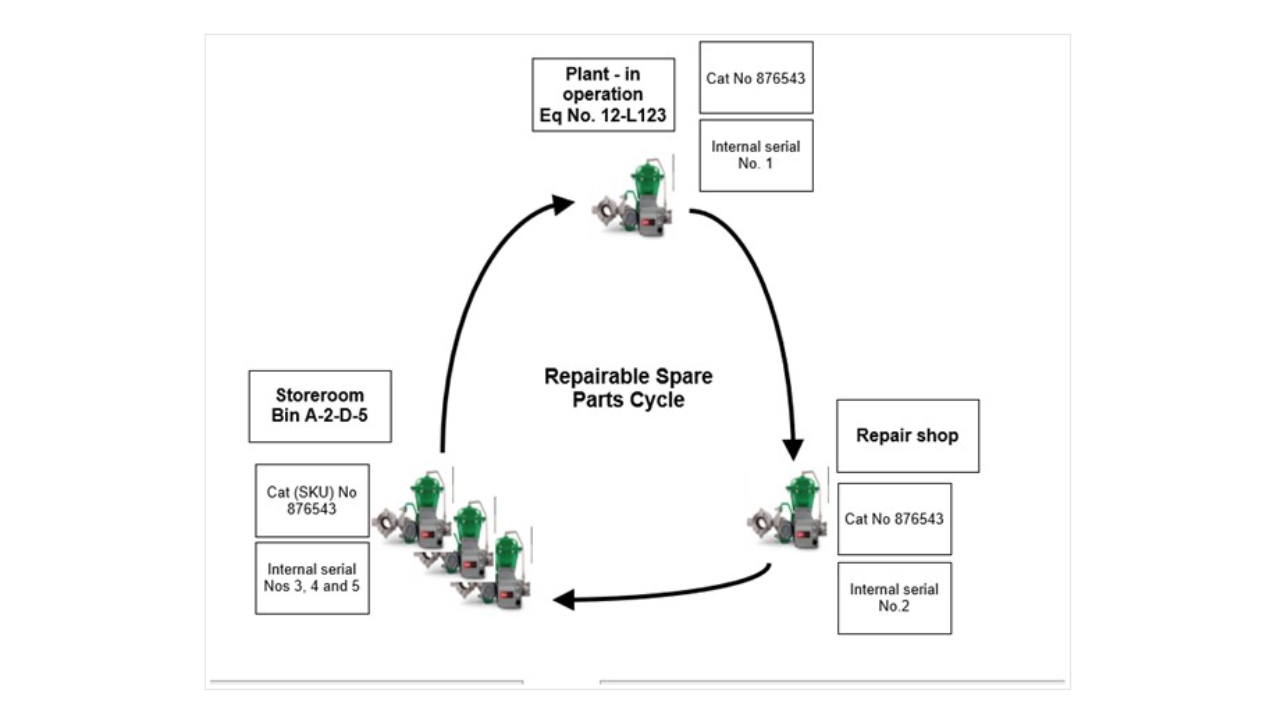

Managing Repairable Spares