The Edison Principal – More Science than Guesswork for Corrosion Prevention

Jim Deardorff, Superior Coatings Co.

Posted 02/14/2023

The Edison Principal has been developed to solve America’s $1.2 trillion corrosion expense by replacing visible rust with black light active fluorescence. Edison Principal is an analogy based on the failure indicator of the common light bulb invented by Thomas Edison.

Example of the Edison Principal

In a large building there may be hundreds of light bulbs. If one bulb goes out the remaining lights compensate for its loss. The burned- out bulb is easily found and replaced returning the light system to full performance. The total system is a success because the design goal of providing adequate light for the building even if a single failure occurs.

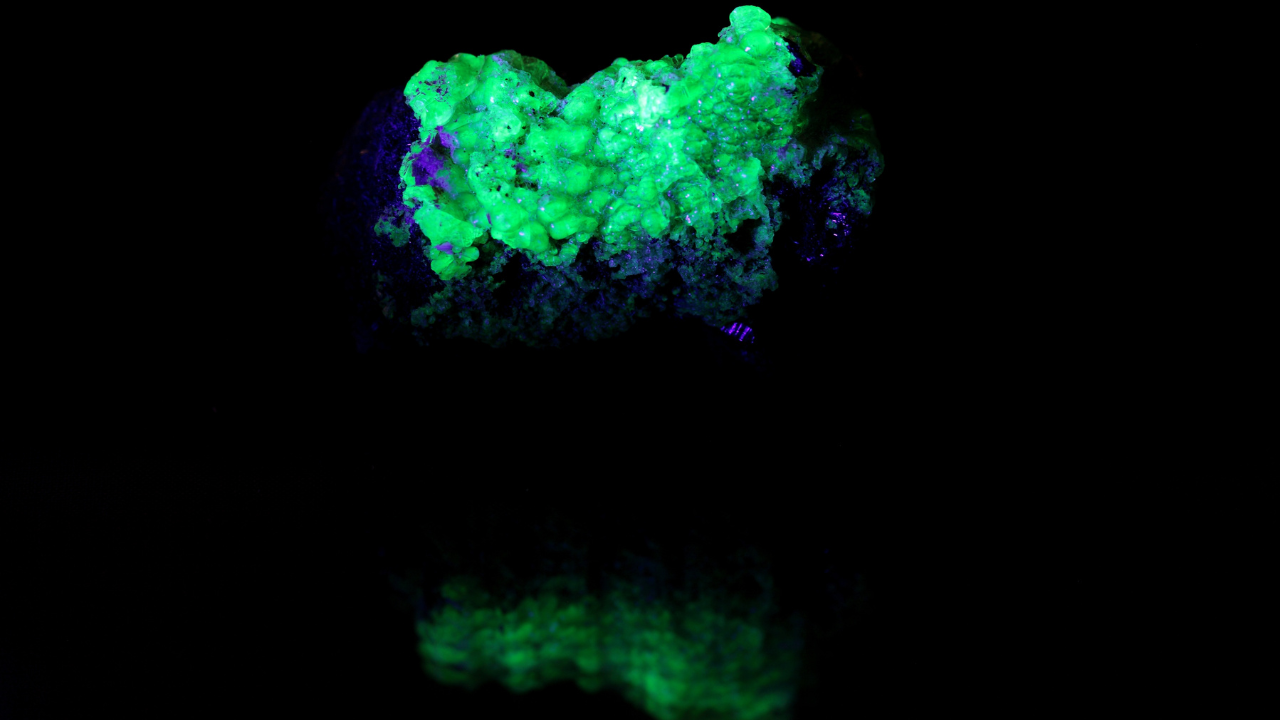

The Edison Principal uses the same defect / detection indicator as the light bulb but, in reverse. Coatings are formulated with an internal fluorescent activator. When these materials are exposed to a specific energy wavelength, known as black light, this additive will fluoresce. This provides a highly visible contrast between modified coatings and the base material.

Fluorescence allows workers to locate and repair coating defects long before system failure occurs and irreversible corrosion damage begins. Over the life of the structure, many coating defects may be found and repaired but, the total system is a success because the design goal of reliable, low cost, corrosion prevention is achieved.

Note, the average worker with 20 x 20 vision can locate a coating defect 50 microns in size (.0019685 inch) in good light and provided adequate time for a thorough visual inspection. The same worker using The Edison Principal can locate a defect 10 microns (.00003937 inch) or smaller even in low light conditions or during production painting operations.

Note, The Edison Principal improves visual location of coating defects up to 1000%.

Fluorescence

More than 3,000 natural and man-made substances can transform invisible electromagnetic energy into longer visible wavelengths that produce fluorescence. These substances react to because they are composed of easily excitable molecules. When exposed to black light illumination, this energy in the form of photons causes one or more electrons to be “kicked up” into a higher energy state. In this state electrons are extremely unstable and will eventually release this excess energy and return to their original ground state. The release of excess energy is what we see as fluorescence.

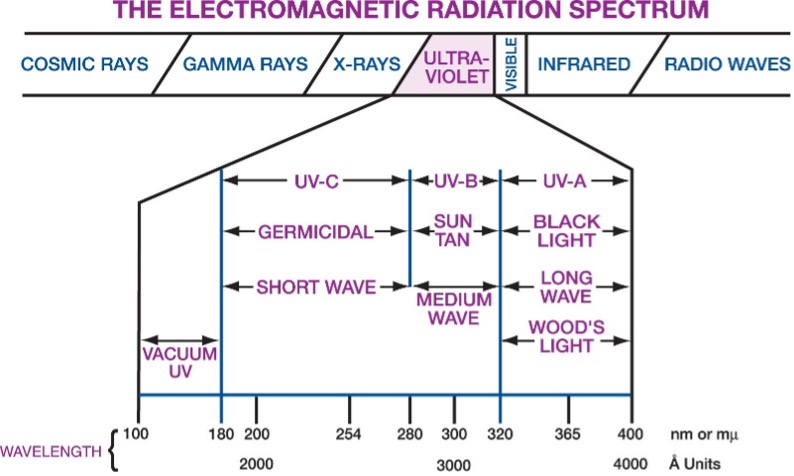

Black Light

Black light also known as Wood’s Light, Long Wave UV, or UV-A is a form of electromagnetic energy that occurs just beyond the visible end of the visible light spectrum. This low energy wavelength covers the range between 320 and 400 nanometers (nm).

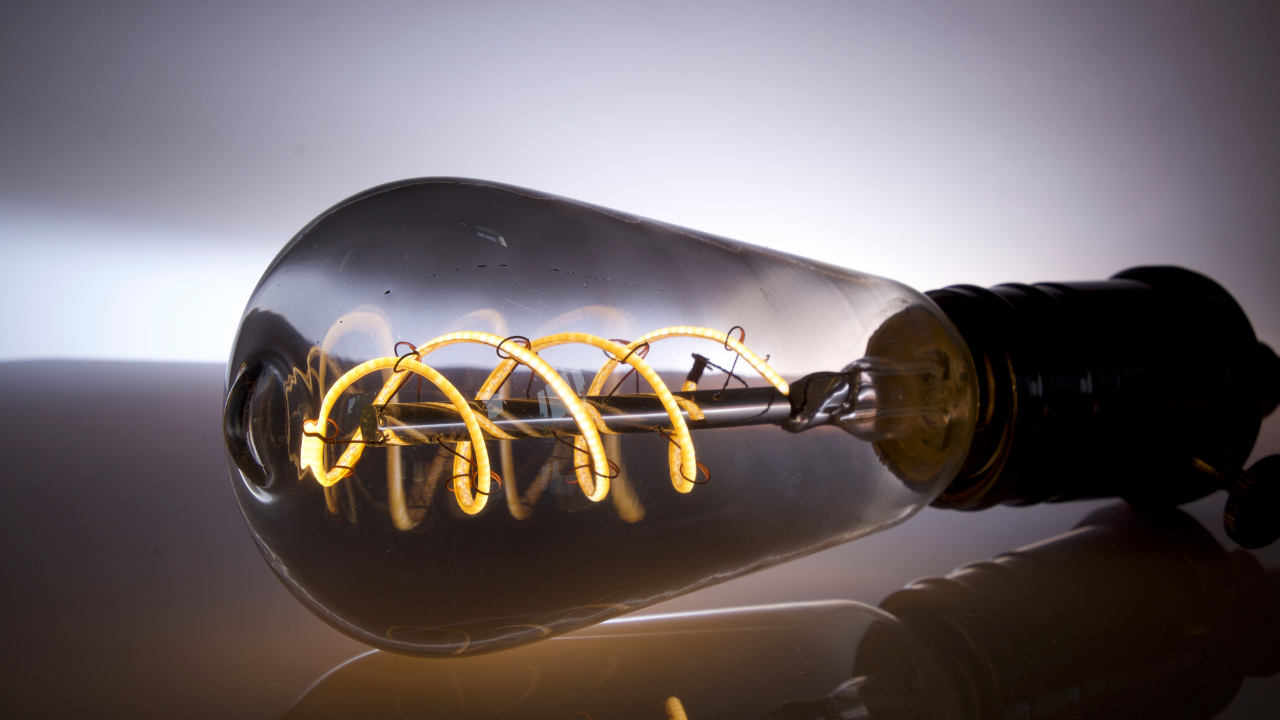

Unlike ordinary light bulbs that produce visible light by moving electricity through a filament wire, black light is created by sending electricity through a tube filled with an inert gas (such as argon) and a small amount of mercury. As an electric spark passes across an electrode this causes the mercury atoms move at high velocity. As these atoms slow down, they release excess energy at 365 nanometers or black light electromagnetic energy.

The Edison Principal Advantages

- The Edison Principal eliminates visible rust from the corrosion equation.

- Increased service life for equipment and infrastructure.

- Reduced corrosion related repairs, downtime, and early replacement costs.

- Improved performance and operational readiness.

- Increased worker safety and moral.

- Reduced wastes and disposal costs.

- A reduction in VOC’s, HAP’s and other types of greenhouse pollutants.

- Improved recycling and remanufacturing potential.

- Lean engineering, a reduced need to over-design assets to resist corrosion.

- Significant savings for corrosion prevention by protective coatings.

Primary Corrosion Sites

Virtually all man- made structures contain areas known as primary corrosion sites. These sites include: welds, joints, corners, cracks, nuts, bolts, fasteners, or wherever there is a dramatic change in surface contour.

The Edison Principal performs a dual function in reducing premature coating failures for primary corrosion sites. For welds and joints black light insures complete saturation of voids. For corners, edges, joints, nuts, bolts, and fasteners black light shows where coatings have cured away from sharp edges and extra coats are needed to achieve proper dry film thickness (DFT).

Even though primary corrosion sites may account for only a small percentage of total surface area, they may, in fact, be responsible for the majority of premature coating failures. PC/NDT provides a maintenance advantage for these problem areas.

Conclusion

There is a definite economic argument for a return to planned maintenance for protective coatings. Design engineers will continue to increase product life by precision engineering and material development. This will create a significant performance gap between coatings and the surfaces they are designed to protect. The argument for maintenance is simple, it takes far less resources to maintain a protective coating than it does to repair or replace the surface it is designed to protect.

James R. Deardorff is a NACE and SSPC member and the president of Superior Coatings, a contract painting company located in Chillicothe, Mo. With almost 20 years of experience in its field, Superior Coatings specializes in the application and maintenance of protective coatings for equipment, structural steel, and concrete. Deardorff is a distributor for protective coatings and NDT inspection equipment. He has also written more than 50 articles and papers on coatings, abrasive blast cleaning, and surface maintenance programs.

Related Articles

Shining a Black Light on Coating Inspections

Fluorescent Cleaning Non-Destructive Testing

Lifetime Coating Systems: Major Problem When Product Life Exceeds Coating Life

Nondestructive Testing for Protective Coatings: Implementing a Lifetime Corrosion Prevention Program