Planning and Scheduling: Planners Should Not

Terry Taylor, IDCON INC.

Planners are oftentimes very talented and great at multitasking; the danger is that they get pulled into duties that take them away from their primary function! This video featuring Terry Taylor, Senior Consultant, discusses what a planner’s role should not be. IDCON’s Work Management: Planning and Scheduling course is the foundation for understanding the roles and responsibilities and the best practices for improving reliability.

Related Articles

Work Order Execution and Data Capture

All of the work of backlog management, planning and priority targeted capacity scheduling are focussed on efficient execution. To ensure that the tasks that need to be done, as per the true requirements of the plant, are done in a timely manner with as little waste of human and material resources as is possible.

All of the work of backlog management, planning and priority targeted capacity scheduling are focussed on efficient execution. To ensure that the tasks that need to be done, as per the true requirements of the plant, are done in a timely manner with as little waste of human and material resources as is possible.

AAA Best Practices Make the Difference

The technical database is all the information needed to plan and schedule efficiently and effectively. Having the eight components of the technical database in place will allow quick determination of the what, how, how long, who, and when of a maintenance job. Application of three simple best practices will generate the most value from the technical database. Focus on developing a technical database that is accurate, accessible, and applied.

The technical database is all the information needed to plan and schedule efficiently and effectively. Having the eight components of the technical database in place will allow quick determination of the what, how, how long, who, and when of a maintenance job. Application of three simple best practices will generate the most value from the technical database. Focus on developing a technical database that is accurate, accessible, and applied.

Proactive Approach to Shutdowns Reduces Potlatch Maintenance Costs

Effective shutdown management is critical to the operation of mills, for without well-planned and executed shutdowns, equipment reliability suffers, and the mill pays the price in poor quality and lost production. Becoming proficient at managing shutdowns is a way to reduce overall downtime costs so that shutdowns themselves do not consume the savings they are capable of generating.

Effective shutdown management is critical to the operation of mills, for without well-planned and executed shutdowns, equipment reliability suffers, and the mill pays the price in poor quality and lost production. Becoming proficient at managing shutdowns is a way to reduce overall downtime costs so that shutdowns themselves do not consume the savings they are capable of generating.

How Service Parts Planning Impacts Machine Uptime

Having the part available in the network has a huge impact on service performance. This also means choosing which parts not to hold is equally crucial, because remember, you can’t have them all. Life is about making choices. If anything, good tools will allow parts planners to present the executive team with several scenarios from which to choose. They can then make a choice based on solid calculations and foresight into cost versus service performance.

Having the part available in the network has a huge impact on service performance. This also means choosing which parts not to hold is equally crucial, because remember, you can’t have them all. Life is about making choices. If anything, good tools will allow parts planners to present the executive team with several scenarios from which to choose. They can then make a choice based on solid calculations and foresight into cost versus service performance.

The What, Why, How of Wrench Time

Wrench time is a measure of crafts personnel at work, using tools, in front of jobs. Wrench time does not include obtaining parts, tools or instructions, or the travel associated with those tasks. It does not include traveling to or from Obviously, it does not include break time. These non-wrench time tasks are often necessary to get work done, but are not "wrench time." The craftsperson is in a delay situation. We should also ask ourselves whether the crafts personnel perform tasks efficiently while they are on tools in front of jobs. This is a legitimate question, but not answered by wrench time. Nonetheless, if we increase the time employees are "on the job," we should get more work done.

Wrench time is a measure of crafts personnel at work, using tools, in front of jobs. Wrench time does not include obtaining parts, tools or instructions, or the travel associated with those tasks. It does not include traveling to or from Obviously, it does not include break time. These non-wrench time tasks are often necessary to get work done, but are not "wrench time." The craftsperson is in a delay situation. We should also ask ourselves whether the crafts personnel perform tasks efficiently while they are on tools in front of jobs. This is a legitimate question, but not answered by wrench time. Nonetheless, if we increase the time employees are "on the job," we should get more work done.

Tips for Maintenance Planning

The work process we call maintenance planning can almost always be improved in any given mill or plant. In fact in most plants we visit maintenance planners don’t plan. Planners do all kinds of tasks except work order planning.

The work process we call maintenance planning can almost always be improved in any given mill or plant. In fact in most plants we visit maintenance planners don’t plan. Planners do all kinds of tasks except work order planning.

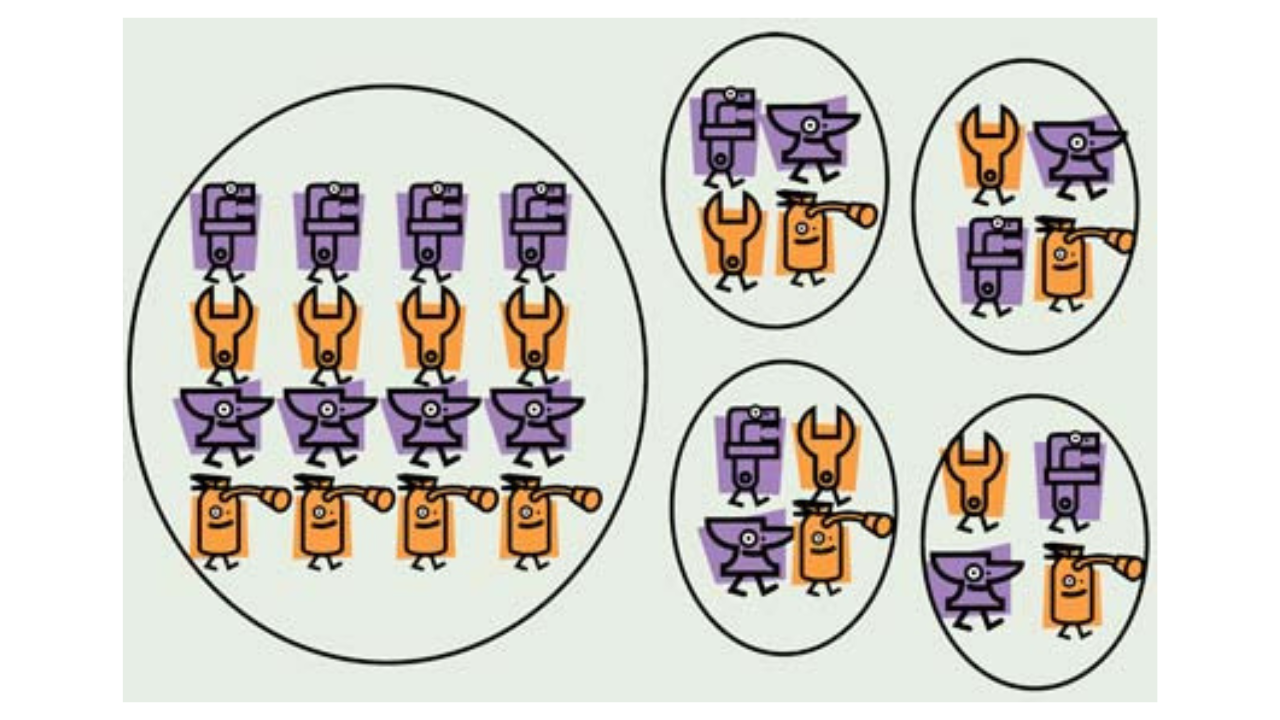

Centralized Maintenance vs. Decentralized

Companies often ask if maintenance planning and scheduling will work if they have a decentralized maintenance organization. Yes, it will. In fact, they need planning and scheduling just as much as a centralized shop. Let's review why.

Companies often ask if maintenance planning and scheduling will work if they have a decentralized maintenance organization. Yes, it will. In fact, they need planning and scheduling just as much as a centralized shop. Let's review why.