Maintenance Crisis Song

Joel Leonard

Related Articles

An Introduction to the Maintenance Scorecard

The Maintenance Scorecard is the first book to seriously tackle the issue of aligning asset management with other areas of corporate activity. This is a particularly relevant topic given the growing importance of the area as a source of strategic advantages and as a centre for risk management.

The Maintenance Scorecard is the first book to seriously tackle the issue of aligning asset management with other areas of corporate activity. This is a particularly relevant topic given the growing importance of the area as a source of strategic advantages and as a centre for risk management.

Maintenance Management Legends

There are many paradigms and legends surrounding maintenance management in plants. Often, the legends are known to be untrue, but people live with them because it is politically correct, or simply convenient. To be successful in improving equipment reliability and maintenance management, plants must break the legends that exist in their organizations. Some of the legends will be addressed in this article. You may find that these legends are uncomfortably close to describing how your plant operates.

There are many paradigms and legends surrounding maintenance management in plants. Often, the legends are known to be untrue, but people live with them because it is politically correct, or simply convenient. To be successful in improving equipment reliability and maintenance management, plants must break the legends that exist in their organizations. Some of the legends will be addressed in this article. You may find that these legends are uncomfortably close to describing how your plant operates.

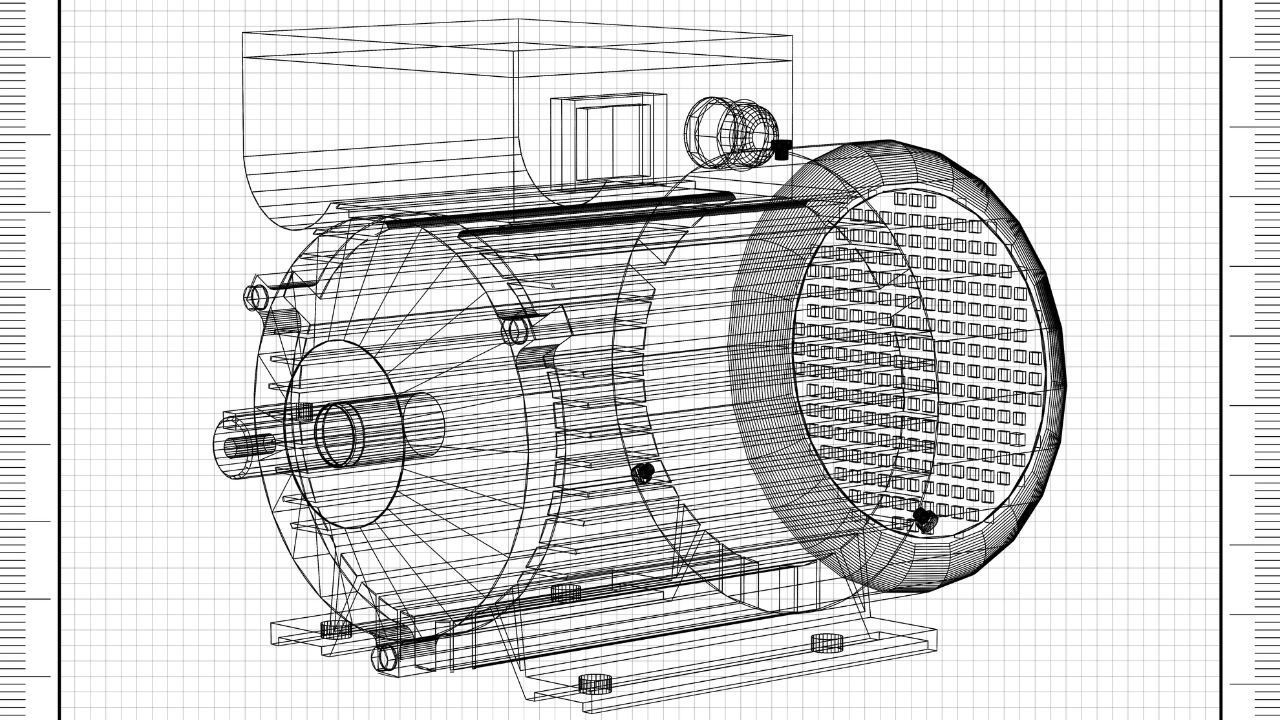

Electrical Motor Diagnostics: Impact of Electric Motor System Maintenance and Management

he application of motor systems maintenance and management programs have the potential impact of saving industry an initial $26.5 Billion in electrical energy costs while reducing greenhouse gas emissions by over 3,000 Mega-Tons per year. The individual impact on production availability is also significant, by reducing troubleshooting and evaluation time by over 50%, motor repair by over 30% and general motor-system related labor by up to 50%, following the application and sustainment of the program. In this article, we are going to cover three opportunities obtained through the application of the Electrical Motor Diagnostic component of an overall program.

he application of motor systems maintenance and management programs have the potential impact of saving industry an initial $26.5 Billion in electrical energy costs while reducing greenhouse gas emissions by over 3,000 Mega-Tons per year. The individual impact on production availability is also significant, by reducing troubleshooting and evaluation time by over 50%, motor repair by over 30% and general motor-system related labor by up to 50%, following the application and sustainment of the program. In this article, we are going to cover three opportunities obtained through the application of the Electrical Motor Diagnostic component of an overall program.

What Is Facilities Management? Challenges, Solutions, & More

Maintenance isn’t exciting. For many, it’s a chore, something they’ll rather skip. Poor facility maintenance often marks the start of a downward spiral–a slippery slope you must avoid. But how? Enter facilities management: your ally in connecting people, processes, and systems.

Maintenance isn’t exciting. For many, it’s a chore, something they’ll rather skip. Poor facility maintenance often marks the start of a downward spiral–a slippery slope you must avoid. But how? Enter facilities management: your ally in connecting people, processes, and systems.

Maintenance Key Performance Indicators (KPIs)

It is often said that "what gets measured gets done". And getting things done, through people, is what management is all about. Measuring things that get done and the results of this effort is an essential part of successful management, but too much emphasis on measurements, or the wrong measurements may not be in your company's best interests.

It is often said that "what gets measured gets done". And getting things done, through people, is what management is all about. Measuring things that get done and the results of this effort is an essential part of successful management, but too much emphasis on measurements, or the wrong measurements may not be in your company's best interests.

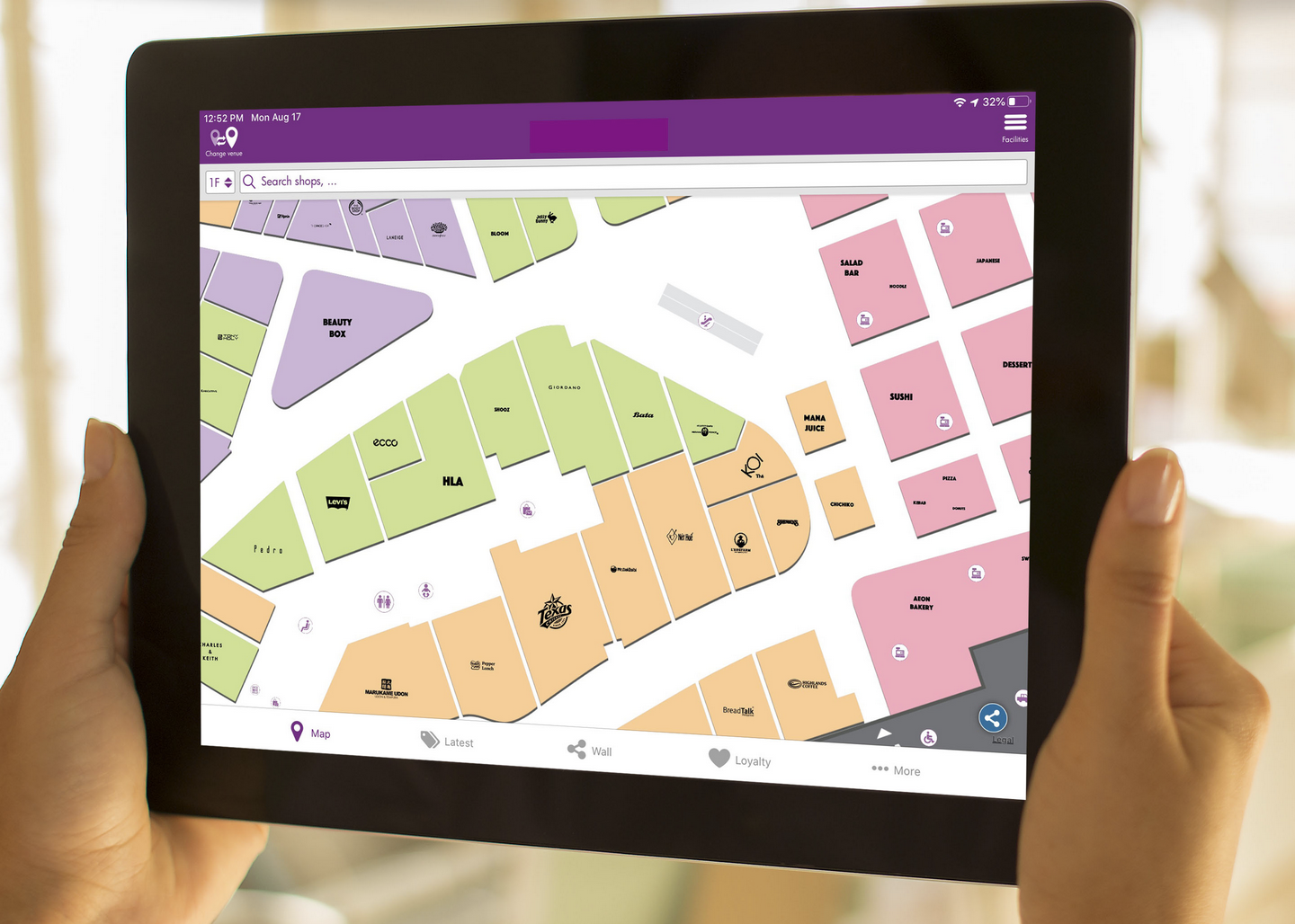

Managing Today's Castles with InMapz

If you are managing a large facility using blueprint floor plans and spreadsheets to track assets, this article is for you. If, the last time you had a water leak during off hours and it took the emergency repair tech a half hour to get to it after wading thru paper maps, this is for you. If your HVAC repair technician got lost on the roof while looking for unit #34 that required maintenance, this might be useful. If your employees have your facilities management team on speed dial, then this was written for you.

If you are managing a large facility using blueprint floor plans and spreadsheets to track assets, this article is for you. If, the last time you had a water leak during off hours and it took the emergency repair tech a half hour to get to it after wading thru paper maps, this is for you. If your HVAC repair technician got lost on the roof while looking for unit #34 that required maintenance, this might be useful. If your employees have your facilities management team on speed dial, then this was written for you.

Maintain Pumping Systems Effectively

Effective pump maintenance allows industrial plants to keep pumps operating well, to detect problems in time to schedule repairs, and to avoid early pump failures. Regular maintenance also reveals deteriorations in efficiency and capacity, which can occur long before a pump fails. Wear ring and rotor erosions, for example, can be costly problems that reduce wire-to-water efficiency by 10% or more. The amount of attention given to maintenance depends on how important a system is to a plant’s operations.

Effective pump maintenance allows industrial plants to keep pumps operating well, to detect problems in time to schedule repairs, and to avoid early pump failures. Regular maintenance also reveals deteriorations in efficiency and capacity, which can occur long before a pump fails. Wear ring and rotor erosions, for example, can be costly problems that reduce wire-to-water efficiency by 10% or more. The amount of attention given to maintenance depends on how important a system is to a plant’s operations.