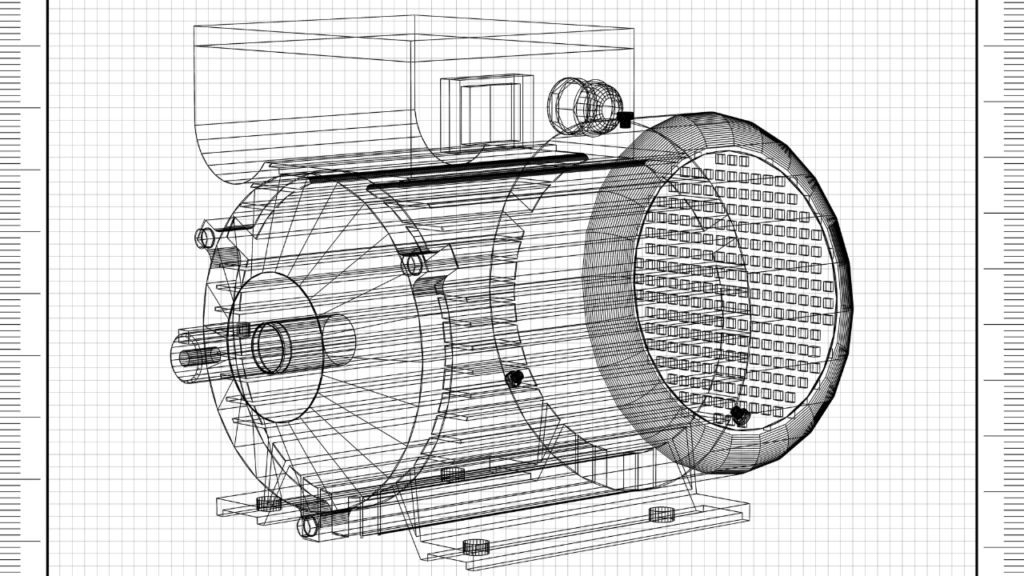

Maintain Pumping Systems Effectively

Effective pump maintenance allows industrial plants to keep pumps operating well, to detect problems in time to schedule repairs, and to avoid early pump failures. Regular maintenance also reveals deteriorations in efficiency and capacity, which can occur long before a pump fails. Wear ring and rotor erosions, for example, can be costly problems that reduce wire-to-water efficiency by 10% or more. The amount of attention given to maintenance depends on how important a system is to a plant’s operations.