Vibration Analysis: Interpreting the Vibration Signature of Plant Equipment.

Chuck Young

Interpreting the vibration signature of plant equipment.

Vibration analysis, properly done, allows the user to evaluate the condition of equipment and avoid failures. Maintenance personnel can minimize unplanned downtime by scheduling needed repairs during normal maintenance shutdowns. How can you interpret — at a glance — the comprehensive spectrum information available? In layman’s terms, here is how to interpret the vibration signature of rotating equipment. The vibration signature is the typical pattern of vibration an individual piece of machinery produces while in operation. You can learn to recognize misalignment, a defective bearing, bent or loose parts — and tell them apart – to determine the vibration signature and what the cause of it is.

Unscheduled downtime may cost tens of thousands of dollars per hour. Fortunately, modern vibration analysis equipment and software predict developing problems so that repair happens before disaster strikes. While these sophisticated tools offer many automated features and capabilities, it still takes a basic understanding of vibration analysis to use them effectively. Plant maintenance personnel having this knowledge also have fewer emergencies — and happier bosses.

In the past, vibration analysis required dialing an instrument through the full spectrum to identify frequencies at which vibration was prominent. The operator then compared the peak frequencies with the operating speed and consulted a chart for likely causes. One advantage of that method was that the operator gradually developed a sense of how equipment vibrates and why certain problems occur at the same multiples of the rotating speed.

The latest generation of vibration analyzers has more capabilities and automated functions than their predecessors had. Many units display the full vibration spectrum of three axes simultaneously — providing a snapshot of what is going on with a particular machine. But despite such capabilities, not even the most sophisticated equipment successfully predicts developing problems unless the operator understands and applies the basics of vibration analysis.

What follows are the basic concepts of vibration analysis that operators in the past learned the hard way through 20 years of hands-on experience. Besides tips on how to record and interpret vibration readings, there is also an example that shows how some of these principles might apply in a typical situation.

Collecting the data — what is important?

First things first. The first and most important step is to gather complete data. That means obtaining a full-spectrum vibration signature in three axes (horizontal, vertical, and axial) on both ends of the motor and the driven equipment. Busy predictive maintenance personnel take only one reading and hope to spot emerging problems. Unfortunately, some problems show up in only one axis. Unexpected machinery failure damages the credibility of vibration analysis whereas comprehensive data (from the full-spectrum vibration signature) should have predicted the problem.

When looking at a vibration signature, it helps to think in terms of multiples of the rotating speed. Because not all plant equipment operates at the same speed, this simplifies analysis. Rotor unbalance, for instance, usually shows up at rotating speed. Mechanical problems — such as a bent shaft, bad coupling, or oversized bearing housing — tend to appear at 2 x rpm.

Vibration frequencies at higher multiples of the rotating speed correspond with the number of components in a specific rotating part, such as the number of balls in a bearing. Other sources of vibration frequencies at multiples of the rotating speed may include fan blades, impeller vanes, rotor bars or stator slots, or some combination thereof.

The nameplate speed probably is not the exact running speed of the motor. It is based on the manufacturer’s average speed for that particular motor design. The actual speed of an induction motor is always lower than the synchronous speed. Be sure to consider this, especially when looking at higher frequency ranges. Using a synchronous rpm of 1,800, for example, might prompt a technician to look for something with 53 components if there is a peak at 95,400 cpm (95,400/1800 = 53). If the actual running speed was 1,766 rpm, the same peak at 95,400 cpm would really indicate 54 rotor bars (95,400/1766 = 54).

Ball or roller bearings have several specific frequencies associated with them. The ball-passing frequency, for instance, depends on the number of rolling elements in a particular bearing. Be aware of differences among manufacturers in the ball complement of a particular bearing size. One manufacturer may use 8 balls in a particular bearing; another may use 9 in the same bearing. Watch out for max bearings, too. These are designed with more balls than standard bearings to increase load capacity.

The number of balls and the actual speed of the motor are factors in determining the frequency at which to expect rolling element problems. Inner and outer race defects show up at specific frequencies as well. Because the circumference of the outer bearing race is greater than that of the inner race, the rate at which balls pass a race defect will differ. The frequency at which these defects manifest themselves depends on several things–the speed at which the bearing is rotating; the number and diameter of balls in the bearing; and the circumference of the inner and outer races.

The programs for many vibration analysis equipment and data collectors store this bearing information in a database. To make the most of these programs, though, it helps to work with a service center that provides detailed repair reports, including bearing size and manufacturer. This eliminates guesswork when a problem arises.

Aerodynamic or hydraulic forces occasionally show up in a vibration signature. If a 1,775-rpm motor has 7 fan blades, a peak may occur at 12,425 cpm (1775 x 7 = 12,425). A 5-bladed pump impeller rotating at 1,450 rpm could have a peak at 7,250 cpm. Normally, these peaks are of a low magnitude. While interesting, they are of no concern unless resonant frequency problems occur. If the amplitude — the height — of the peak increases significantly since the last reading, it may indicate a developing problem like a high fan blade passing a fixed protrusion or a damaged impeller blade.

Resonance becomes a problem when the natural frequency of the entire assembly is close to the vibrating frequency of one part of the rotating system. With existing equipment, this normally occurs only when something changes. Installing a lighter-weight replacement pump or motor, for example, may alter the natural frequency of the assembly enough to create a resonance problem. A replacement shaft with a different diameter could change the resonant frequency of the package (motor/base/driven equipment). The change could also be structural — a cracked weld that reduces overall stiffness.

The high readings show a resonance problem at 1,200 cpm (the motor rpm) that occurred when a new sole plate was installed on a motor and pump. This was verified by a bump test (see sidebar for definition of Resonance). The supporting structure for the motor that elevated it to line up with the pump literally rang like a bell, resonating at 1,200 cpm. If in doubt, the bump test is a quick way to identify resonance problems.

Sometimes an operator will identify a peak at very high frequencies of 30,000 cpm or higher. This usually corresponds to a rotor bar- or slot-passing frequency. These frequencies are multiples of the running speed, so they will be much higher for high-speed motors than for low-speed motors. For example, a 150 hp motor with 65 rotor bars that operates at 3,565 rpm would have a bar-passing frequency of 231,725 cpm (3565 x 65 = 231,725). By contrast, a 65-bar rotor running at 300 rpm would exhibit a bar-passing frequency of 19,500 cpm (300 x 65 = 19,500).

Defective rotor bars generally increase the amplitude of the bar-passing frequency of the motor. Defective rotor bars usually cause a pair of symmetrical 1 Hz side-bands that appear as additional peaks bracketing the rotor-passing frequency for the motor.

On 60 Hz systems, electrical problems almost always show up at 7,200 cpm (60 cycles per second x 60 seconds x 2 = 7,200 cpm). Possible causes include:

- voltage unbalance,

- eccentric air gap that may be the result of an oversized or out-of-concentric bearing housing,

- a rotor shaft bent between the bearings,

- defective rotor bars, or

- shorted turns on a synchronous rotor.

Chopping the power while monitoring the vibration signature is an effective check for electrical problems. If a peak at 7,200 cpm disappears instantly when the power is cut, the problem is electrical in nature. If the amplitude of the peak decreases slowly, the problem is mechanical. This test is especially helpful in differentiating between an electrical problem and a loose bearing housing in a 2-pole motor. A 2-pole motor has a synchronous speed of 3,600 rpm, but it may operate at 3,575 rpm x 2 = 7,150. Differentiating between the two frequencies requires a careful operator.

Variable-frequency drives make interpreting data even more challenging, since inverter-driven induction motors may be operating far below nameplate speed. Even electrical problems are more difficult to diagnose, because the frequency varies. As a point of reference, you must know and record the actual speed when collecting the vibration data.

The newer generations of Fast Fourier Transform analyzers may indicate a peak at a very high frequency, a peak not identified before by older equipment. Unless it is of considerable magnitude, or the amplitude increases over time, it usually does not indicate a problem. A report of the sudden appearance of a peak at high frequency may indicate that the vibration tech has a new analyzer, rather than a machinery problem.

Axis-specific problems sometimes appear. A high vertical reading, for example, is usually caused by a base-related problem. This may mean soft feet, loose base-bolts, structural looseness, or a disbonded sole plate. High horizontal readings are commonly associated with unbalance in the rotating elements.

High axial readings generally indicate misalignment. The cause may be external, like coupling misalignment, or internal, like mechanical looseness or a bent shaft. Looseness may include a worn coupling, an oversized bearing housing, or with a sleeve bearing motor, excess bearing-to-shaft clearance.

Normally, the magnitude of axial readings is no more than half of radial readings. A so-called high axial reading may not be of high absolute magnitude but rather disproportionately high in comparison with radial readings. A velocity reading of 0.08 in the vertical axis is higher than a 0.06 axial reading, but the axial reading is more likely to indicate a problem.

With a little intuition and a vibration signature for three axes taken at both ends of the driver and both ends of the driven equipment, it is not difficult to identify the source of a problem.

Putting it all together

How basic principles of vibration analysis might be applied in a typical in-plant situation can be illustrated with a pump and motor unit that shows high vertical frequencies at one end of the motor and high axial readings at the other. This suggests a combination of problems, including either misalignment or a problem with the sole plate or base. To diagnose the problem, the technician might consider the following.

High vertical readings are not often associated with alignment problems. However, a partially disbonded sole plate affects the alignment on the end of the motor nearest the disbonded area. This happens because the same torsional forces that cause the shaft to rotate are trying to rotate the stator and frame in the opposite direction. If a corner of the sole plate is not bonded, that corner of the motor may lift, allowing the frame to twist and produce higher-than-expected axial readings. This frequently happens when the sole plate is badly disbonded and the torque is high as with a low-speed, high-horsepower motor.

To find the cause of the vibration in this case, the first step might be to check and correct any alignment problems. If the alignment is okay, check the sole plate or base for obvious indications of problems like cracked concrete or broken welds. Dirt or product may cover these, so always check for sole plate movement with a dial indicator mounted on a beam and supported independently from the motor foundation.

To do this, determine the direction of machine rotation and set up the dial indicator to read the lifting movement of the sole plate during starting. The force exerted on the sole plate by an electric motor during acceleration is in the opposite direction of that acting on the rotor and considerably higher than during normal operation. For example, a NEMA Design B motor exerts 200 percent of rated torque at 80 percent of rated speed.

Zero the indicator with the motor shut down; then watch the indicator during starting. A solid foundation prevents movement. So if the sole plate lifts even a few thousandths of an inch, then it means trouble. Once a sole plate starts to separate from the underlying foundation, the force exerted during each successive start continues to peel it away. The decreasing bond area provides less and less resistance to the torsional forces, so the rate of separation increases.

Making it happen

Examine high-frequency peaks and match them to the expected frequencies for the bearings and gears, if any, as well as the rotor bar-passing frequency. While the mere presence of a peak may not indicate a problem, an increase in magnitude probably does.

A high axial reading on one end of the motor usually means the source of the high reading is on that end. A rubbing labyrinth seal, for example, causes a considerably higher axial reading on the affected end. Higher axial readings on one end indicate a defective bearing in a gearbox. Knowing the reduction ratio and the speed of intermediate shafts allows the technician to pinpoint the specific faulty bearing or defective gear.

It also is important to keep a file on critical equipment, especially complex machinery like gearboxes. Record information like bearing sizes and brands, the number of gear teeth, fan blades and rotor bars.

Finally, don’t rule out a defective foundation as the cause of vibration. Concrete deteriorates with time and exposure to moisture. In cold climates, frost-heaves and mud in the underlying ground may affect the foundation of the entire building or make localized areas susceptible to vibration. This may be evidenced by seasonal problems. Are there problems with a particular pump every spring or fall? The problem may be in the underlying ground rather than the pump or the motor base.

While many larger plants have excellent in-house vibration analysis capability, the answer for smaller plants, or those caught in the budget crunch, may be to out-source this highly technical function. Justification must consider the actual annual cost of downtime, the potential for savings in terms of lost productivity, as well as the cost of training and vibration analysis equipment. Before buying the equipment, make sure the management commitment is there to set up and train an effective preventive maintenance team.

The Electrical Apparatus Service Association Inc. (EASA) is an international trade organization of more than 2,500 electromechanical sales and service firms in 32 countries. Through its many engineering and educational programs, EASA provides members with a means of keeping up to date on materials, equipment, and state-of-the-art technology related to sales, service, and maintenance of motors, generators, drives, controls and other electromechanical equipment.

Chuck Young

Chuck Young is a Senior Technical Support Specialist at EASA: The Electro•Mechanical Authority.

Related Articles

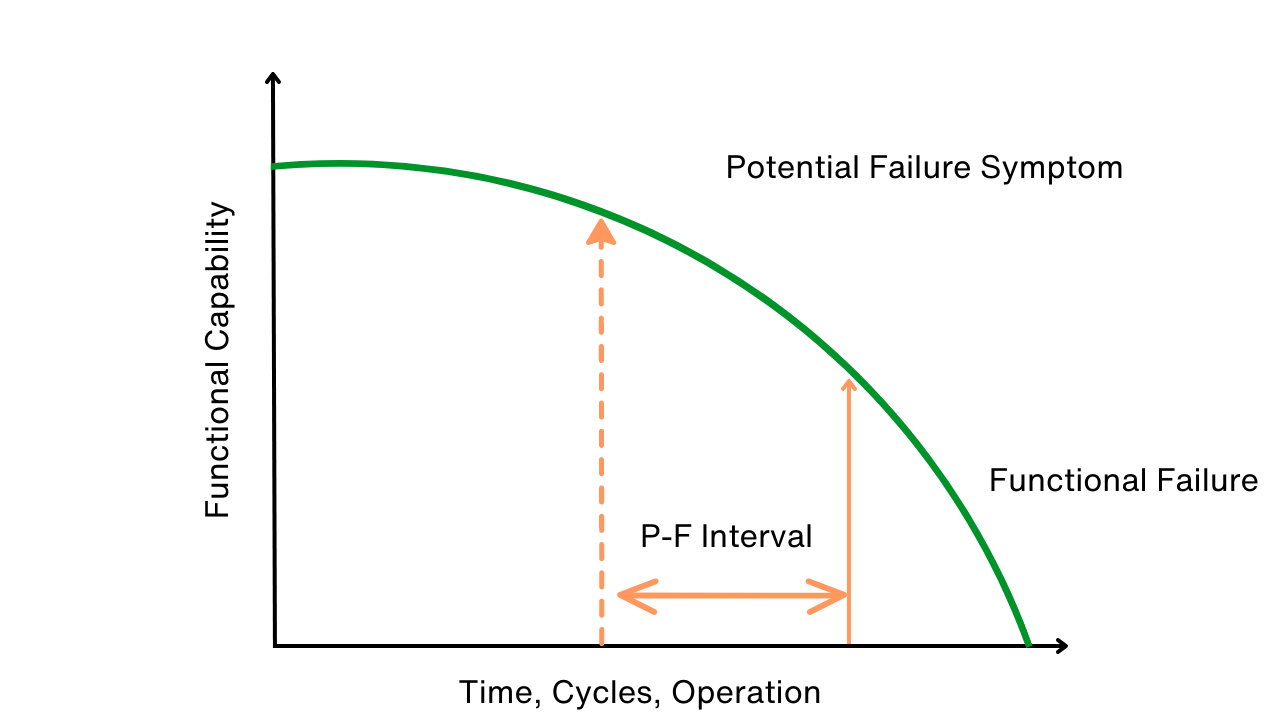

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?

Design for Maintainability