Vibration Pen, Shock Pulse Measurement (SPM), & Vibration Analysis – What’s the Difference?

Joe Cox, MaintenanceWorld.com

There are three major types of tools for finding bearing defects using vibration techniques:

- Vibration pen

- Shock Pulse Measurement (SPM)

- Vibration Analysis

Other on-the-run (while bearing operates) techniques are ultrasonic testing and stethoscope.

Which of the tools should you chose for inspections of bearings? The best solution is often a combination of two or three of the tools, but it depends very much on how much rotating equipment you have in your plant, the criticality of that equipment, the speed of your rotating equipment, and how perceptive your organization is to training. A short description of the three techniques follows.

What is a Vibration Pen?

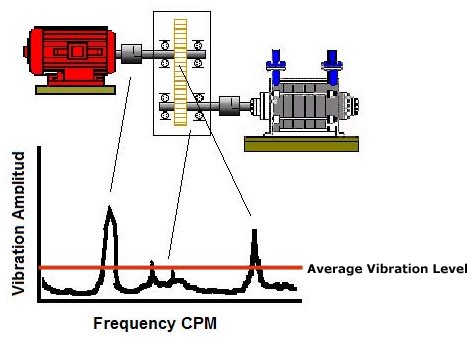

It often measures the average vibration level, measured in in/sec (mm/sec). Since sound also is a vibration, but present in air instead of metal, we can describe the average vibration level as the volume of the vibration. The pen often only provides one, or two numbers that measure how much the machinery vibrates. It doesn’t have the functionality to analyze the vibration, for example, where the vibration originates, or the cause of the vibration. An advantage of the pen is that you can train a person in a few hours in how to use it.

The pen measures the average vibration level while vibration analysis presents the whole vibration spectrum that can be interpreted.

What is Shock Pulse Measurement?

Consider that you have a metal ball that hits a metal bar (1). At the moment of impact, a pressure wave spreads through the material of both bodies (1). The pressure wave quickly dampens out. The pressure wave that first goes through the materials (before it starts to vibrate) is called a “shock pulse”. While the initial Shock Pulse subdues, the materials start to vibrate (2), this vibration wave that is measures by vibration analysis.

A shock pulse meter is very sensitive to detecting any defects in the bearing, but can’t analyze the vibration created after the initial shock pulse. A SPM instrument can be used after about 1-2 days training and is more sensitive to bearing defects than the pen.

What is Vibration Analysis?

People have written long books on the subject. The short description above will have to do for our purposes. Vibration analysis can measure many aspects of the vibration wave, it can for example look at where the vibration is strongest (usually converted into RPM). Compare the vibration spectrum with the popular sound equalizers of the 1980’s, where you can adjust the volume for different frequencies (spectrum). Vibration analysis relies on interpretation of the vibration spectrum. The interpreter can determine if the vibration originates in mechanical looseness, misalignment, imbalance, gears, bearing defects, etc. Unfortunately, it usually takes several years before a person becomes proficient in vibration analysis interpretation.

Other vibration analysis and pen vendors are SKF, CSI (now part of Emerson), Entek (Now Part of Rockwell).

For more about what vibration analysis entails, click here.

Related Articles

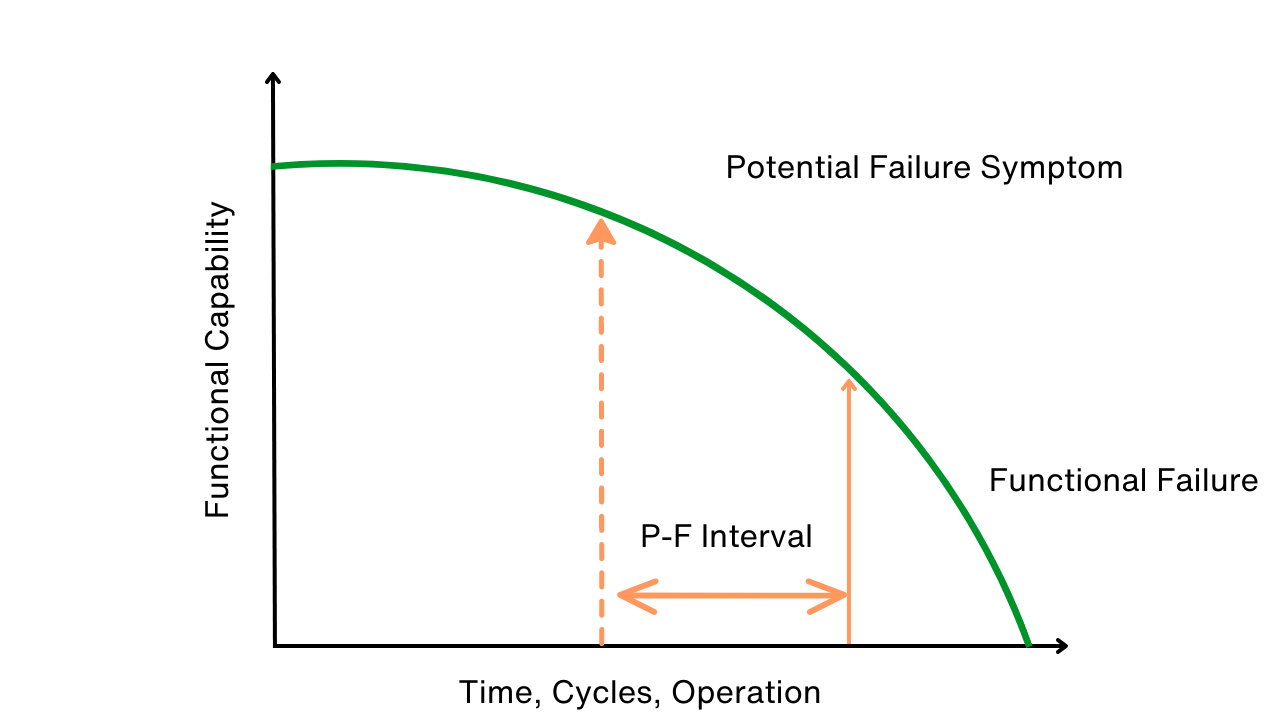

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?

Design for Maintainability