Dynamic Fault Reporting: Maintenance for Infrastructure and Equipment Upkeep

Paweł Bęś, Logistics and Maintenance Marketing Expert, QRmaint

Posted 10/9/2025

The relentless march of industrial and civil progress hinges on the steadfast reliability of its foundational elements: machinery and infrastructure. From the production lines that form the bedrock of global supply chains to the sprawling networks of public infrastructure that keep societies running, consistent upkeeping is not merely an operational goal—it is an economic and safety imperative.

Yet, a crucial vulnerability persists in the traditional maintenance framework: the archaic, unstructured process of fault reporting. The very act of identifying an issue and communicating its precise location and nature is often the first, and most significant, point of failure in the maintenance workflow.

For instance, at the very beginning, we can give an example from Network Rail’s maintenance operations. This may involve processing an estimated 4.2 million work orders annually. This translates to each Maintenance Delivery Unit (MDU) handling a formidable 80,000 to 150,000 work orders per year. Despite this high-volume, structured environment—where about 600 job codes cover 90% of all work—the report pinpoints a critical flaw: the archaic and unstructured process of initial fault reporting. This initial act of identifying an issue and communicating its precise location and nature is recognized as the “first, and most significant, point of failure” in the entire maintenance workflow. In fact, in the rail industry, this creates a vulnerability that undermines the efficiency of the massive system built around it.

What is unstructured reporting? What is your current “The Status Quo”?

In countless maintenance departments across industries, the process of fault reporting remains fragmented. This approach is itself relatively inefficient and highly inaccurate. The information chaos stems from relying on non-standardized communication channels and documentation methods.

Typical Reporting Methods and Their Pitfalls:

- Paperwork and Manual Logs: Hand-written forms are notoriously susceptible to illegible script, lost documents, and delayed transmission.

- Phone Calls and WhatsApp Messages: While immediate, these methods are another example of an unstructured process. Verbal descriptions are prone to misinterpretation. This led to another conclusion: data can be better standardized within a Computerized Maintenance Management System (CMMS). A report like “The motor on the third floor is making a strange noise,” given over the phone or via WhatsApp, is dangerously vague and leads to significant time being wasted by technicians searching for the problem. In the CMMS, you can select the error code directly and choose the closest possible description from the dropdown menu if needed.

- Varying Stakeholder Standards: Operators, foremen, and floor staff often have different levels of training and attention to detail. This lack of a unified reporting standard results in inconsistencies, where one person reports a “major failure” and another reports a “small note” for the exact same issue.

This operational friction ensures that valuable time is spent on administrative and search tasks rather than on actual repairs. So, in our opinion, this directly contributes to increased unplanned downtime and inflated operational costs.

This is particularly challenging for infrastructure assets that are dispersed and non-mobile, or not conducive to simple QR code or NFC tag scanning. For example, a case such as a broken pipe installation hidden behind a wall, a defect deep within a utility tunnel, or a structural crack on a distant overpass. These assets, though challenging to tag and find, still require maximum precision in fault location.

What about accuracy: Let’s introduce you to the Dynamic Fault Reporting

The solution to this systemic inefficiency lies in the adoption of Dynamic Fault Reporting—a digital shift that focuses on providing maximum spatial and descriptive accuracy within a centralized. It’s about a more structured system, such as a modern CMMS. The concept I’m discussing extends beyond the limitations of asset-tag-based identification. In this case, you get visual and location-centric reporting.

Dynamic Fault Reporting: Pinpointing the problem visually

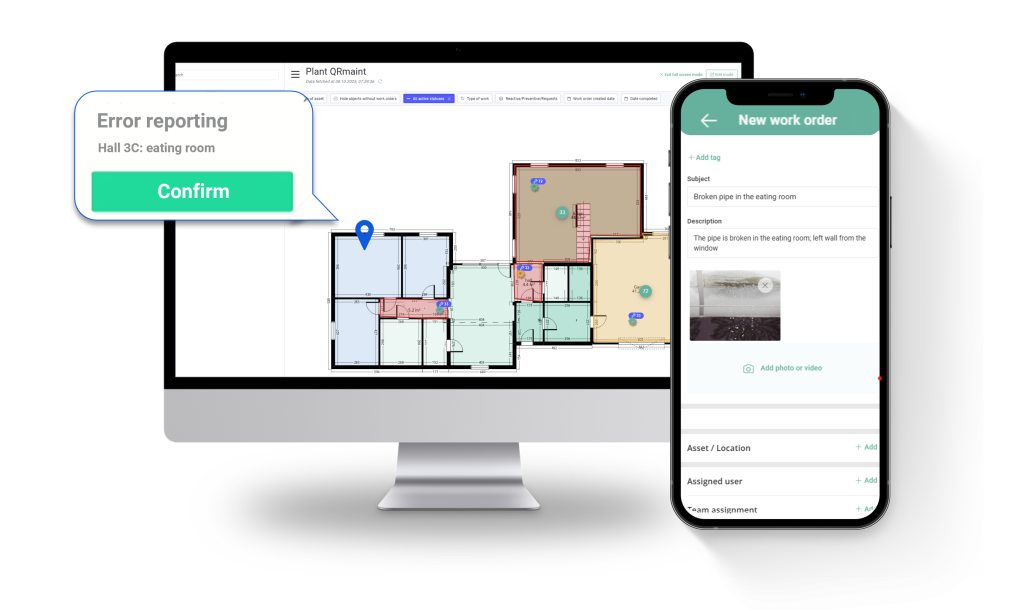

Dynamic fault reporting involves precisely pinpointing an issue on a visual representation of the asset or location. You can mark the exact location with a tag on the map in a CMMS mobile application. In fact, it is exemplified by the ability to “mark on the map”—or more accurately, to click, tap, or draw on a digital plan, floor blueprint, or technical schematic. So, whatever infrastructure map you have, it is intended to indicate the exact location of the fault.

Key values of the dynamic fault reporting in the CMMS system:

- Visual and Map-Based Location: Interactive maps and floor plans: The user can navigate a digital twin or a simple floor plan of a production facility, building, or linear infrastructure (like a road network). Instead of scanning a non-existent tag, the user taps the location, for example, on a wall in a remote storage area, an area on a pipe rack, or a specific coordinate on a geographical map.

- Pinpointing the Fault: This visual act of placing a virtual “pin” or drawing a circle with a finger on a mobile screen allows for granular accuracy that a general “Asset #47 is faulty” request can never achieve.

Rich Contextual Data Capture:

- Multimedia Integration: The core limitation of older systems is the text-only report. Dynamic reporting encourages the user to attach photographs and videos directly to the pinpointed location. A picture of a visible oil leak or a short video of an unusual machine vibration provides irrefutable evidence and a superior diagnostic area.

- Standardized Failure Codes and Dropdown Lists: While the location is dynamic, the description must be structured. Users select from pre-defined, user-configurable Problem, Reason, and Action codes—effectively translating an unstructured observation into structured data.

Automated Workflow and Triage:

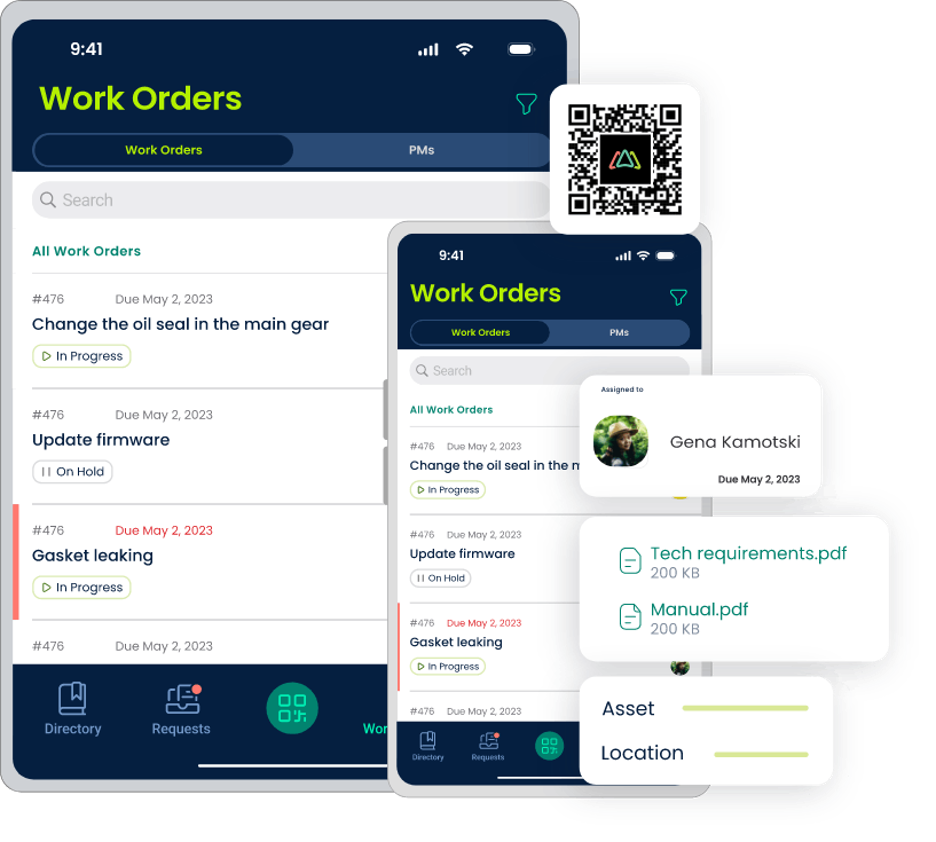

- Instant Notification: Once a fault is identified and submitted in the CMMS app, the system instantly notifies the relevant maintenance team or technician, based on the asset type and location. This eliminates the delay and confusion associated with email or phone calls.

- Prioritization and Tracking: The report is assigned a unique ID and priority level immediately and placed into a centralized work order queue. The system automatically creates a complete, trackable digital audit trail.

Overcoming the “Untaggable” Challenge in Maintenance

The inability to physically tag every component is a persistent challenge, particularly in vast infrastructure and densely populated industrial environments.

Where does Dynamic reporting really help?

Infrastructure: For public works, utilities, and civil engineering assets—from street lighting systems to miles of underground piping—placing an NFC tag on every inch is impractical.

Hidden or Difficult-to-Access Assets: As noted in the prompt, issues such as broken installations in hard-to-spot locations (e.g., behind equipment, high up on a gantry, or inside a ventilation duct) cannot be tagged.

The actual value of dynamic fault reporting extends beyond simply getting a technician to the right place faster; it transforms raw observations into “gold dust” data that drives reliability and business performance.

- Enabling Predictive and Proactive Maintenance: Structured failure data, logged with high accuracy over time, forms the foundation for advanced analytics. Maintenance managers can utilize Pareto analysis to identify the 20% of faults that account for 80% of downtime, thereby reallocating resources from reactive repairs to targeted preventive maintenance (PM) or even predictive maintenance (PdM).

- Measurable Performance: By standardizing the reporting workflow, an organization can measure key performance indicators (KPIs) like Mean Time To Repair.

Summary

Well, the traditional, messy fault reporting system—relying on paper, phone calls, and chaotic communication—is no longer sustainable in the 21st-century economy. The modern answer is Dynamic Fault Reporting. This is a CMMS-powered function that provides a visual and highly accurate method for marking and describing faults. You can allow your technicians to precisely pinpoint issues on a digital map or schematic and enrich that report with standardized codes and multimedia.

Don’t forget that we constantly move from descriptive chaos to precise, so data-driven reporting is the single most effective step for an organization.

Paweł Bęś

Paweł Bęś, Logistics and Maintenance Marketing Expert for QRmaint. He is a B2B marketer with 8 years of experience in the logistics industry in the Netherlands. His work included business analysis of distribution and supply chain operations of high-tech companies in EMEA and APAC. He was responsible for directing, coordinating, planning and supervising transportation tasks and internal operations. He is currently responsible for marketing activities at QRmaint, a company that provides CMMS systems for various industries.

Related Articles

Protecting Mission Critical Electronics

The CMMS: Where Data Goes to Die – Unleashing the Potential of Your Maintenance Digital Backbone

CMMS Features that Maintenance Teams Should Use to Improve Maintenance Performance

Maintenance Cloud Operations - Updates are the new Spare Parts

Streamlining Work Order Management for Improved Facility Operations

How to Mitigate Risk with Your Mobile Solution Proof of Concept