Engineering Standards to Help Lower Cost

John Sewell, Consultant, IDCON INC

Posted 04/11/2023

The consistent use of accurate engineering standards represents a huge opportunity to simplify the planning process. Engineering standards cover a wide range of topics from design to operation and maintenance activities. Many already exist and are commonly used across industries. Plant-specific standards take an initial time investment to create, but once written can be reliably used to speed up the planning effort, provide clear instructions to work crews, and help standardize critical and frequent activities.

Engineering standards are formal documents that define standard methods to be used for critical and repetitive jobs that help keep the work safe, repeatable, and effective.

Which Jobs Benefit from an Engineering Standard?

The two primary types of activities that can benefit from an established engineering standard are critical and repetitive jobs.

Critical jobs pose a high environmental, safety, and/or financial risk. Not all jobs justify the effort of developing standards. These jobs may be simple tasks or are for certain equipment that doesn’t have high costs. Before deciding a job isn’t critical enough to justify a standard, make sure to fully understand the cost of not developing one.

Irregularities in the work may be hidden because they occur downstream or are handled by another department. Check with all potential stakeholders when calculating the costs and benefits of a standard.

Repetitive jobs are another class of activity that is well served from engineering standards. The more often a job is done, the more likely that a standard way of doing things can benefit the plant. Begin by identifying the most efficient way to perform a repetitive job and document the practice. Decide on what defines repetitive or frequent. Consider the time saved by standardizing a procedure with the cost of developing the standard.

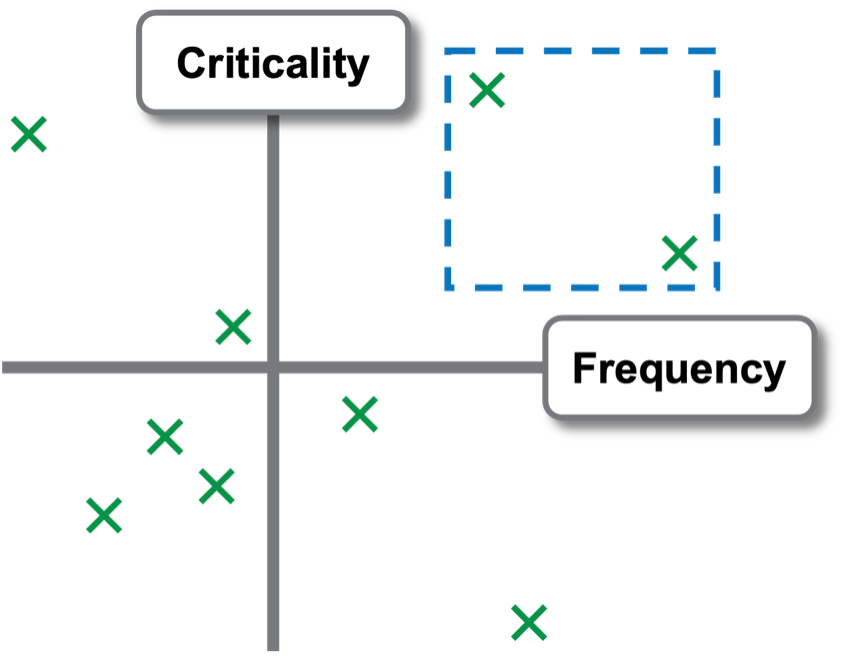

When prioritizing the development of engineering standards, begin by focusing on the combination of most critical and most frequent. Plot jobs to show the relative rankings. The two jobs in the blue box are both critical and frequent and should be the focus for initial engineering standard development.

What are Examples of Beneficial Standards?

To benefit planning, develop engineering standards for these categories:

Design – Equipment design standards, or the lack thereof, can have a big impact on long-term reliability and overall cost. Develop engineering standards that specify the most cost-effective design features and construction materials. Define goals for maintainability and reliability in the design phase of projects. If developing these standards is not cost effective for a small facility, at least specify the use of reliable vendors that have a proven track record of success in your industry.

Fabrication – Many facilities and plants fabricate either materials used in processing or finished products. A common example of a repetitively produced material is piping. Piping is often subject to governing codes and standards used by the industry at large, but plant-specific standards can streamline the planning process. Without established fabrication standards, engineers may have to develop work instructions for every routine job.

Maintenance Prevention – Maintenance prevention activities should be ongoing. These jobs are also critical in reducing overall production cost by preventing failures from developing. The two main categories of maintenance prevention tasks are cleaning and lubrication. Cleaning standards are often required in food-grade plants. Even in mills where there are no jurisdictional requirements for cleaning, the establishment of standards can keep the mill safe and increase the visibility of any potential defects. Properly identifying the correct lubricants, quantities, and lubrication points in a documented standard is the first step in developing world-class lubrication practices.

Inspection – Condition-based maintenance tasks are a key part of asset care programs. Like maintenance prevention, failure detection should be frequent and is critical in keeping life cycle costs of equipment to a minimum. Standards for inspections performed while the equipment is in operation should be given priority for development. Document inspection tasks for each class of equipment and train users on the standards.

Repair – Repair tasks are inevitable and can be good candidates for engineering standards. Some plants find it cost effective to pull and replace equipment and have the repairs performed off-site. Other plants choose to keep repairs in-house and often have dedicated shops or crews who focus on rebuilds. Whichever the case, determine if written standards would be beneficial. Original equipment manufacturer manuals can often be used as the basis for rebuild standards. Add plant-specific quality assurance steps and ensure that crews are aware of the requirements.

Installation – Rotating equipment must be aligned and balanced when installed. The life of bearings is greatly influenced by both factors. Equipment that is aligned and balanced will have lower overall vibration and can remain in service for longer periods of time. Engineering standards set alignment and balancing limits and define standard procedures for how to conduct each job. When developing these standards, make sure to include instructions for typical problems such as soft foot or pipe strain.

What are Best Practices for Engineering Standards?

Focus on the developing engineering standards that are accurate, accessible, and applied.

Accurate – The accuracy of engineering standards is vital. Due to the repetitive and critical nature of the jobs, any errors in the standards can have catastrophic consequences. Spend time developing and reviewing standards that have the appropriate technical foundation. Review standards on a periodic basis and update to reflect current best practices.

Accessible – The accessibility of engineering standards is determined by two factors. The first factor is that the users can locate, download, and use the standards. Keep the standards in an electronic and easily searchable database. Standards can be saved by a classification based on job. For example, saving all fabrication standards together and all repair standards together. Another option is to save the documents by the equipment they are used for. Use a structure that matches the equipment hierarchy in the computerized maintenance management system. The second key factor in standard accessibility is in training end users. Planners, coordinators, engineers, and crews should be trained on what standards are available and when they should be used. Routine training sessions on the specific steps of the standards should be incorporated in the employee’s long term training plan.

Applied – To get the full value of engineering standards, they must be used frequently. Planning can be efficient and safe by applying the appropriate standards. Job packets for critical and repetitive jobs should include any standards that have been developed. Conduct spot checks of jobs and ensure that the standards are available and that the crews understand their use.

How do they Fit into the Technical Database?

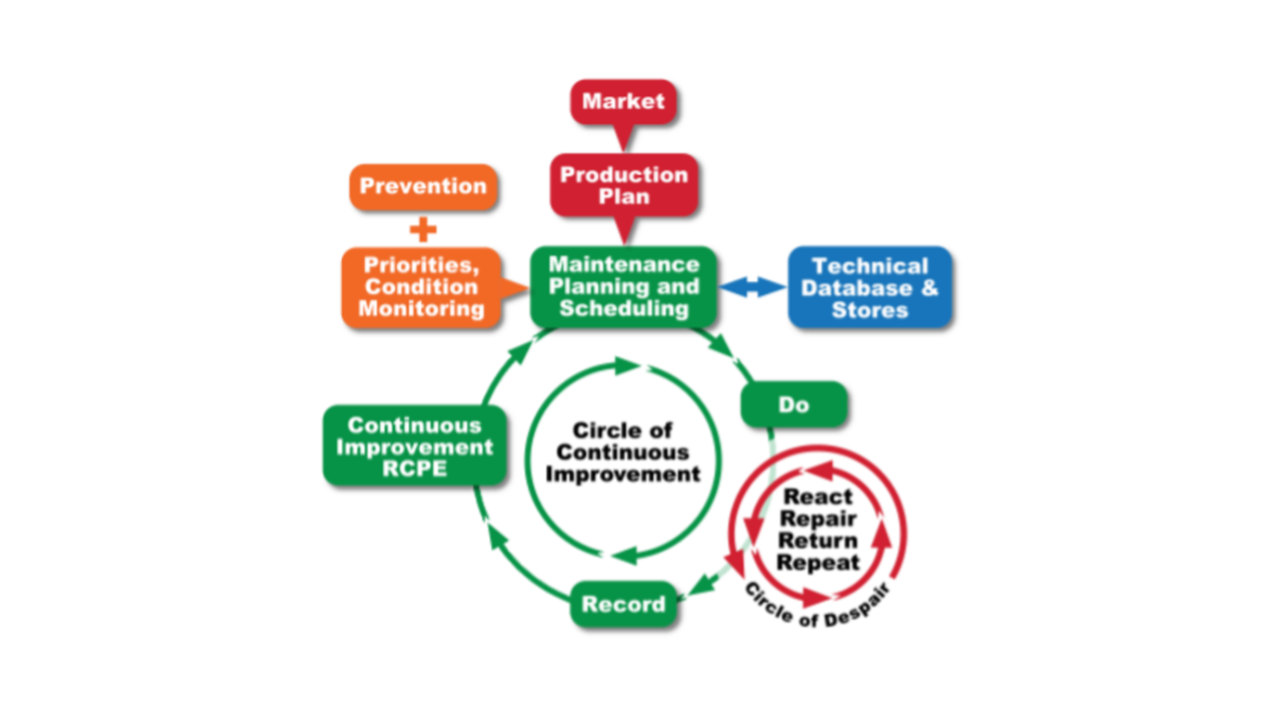

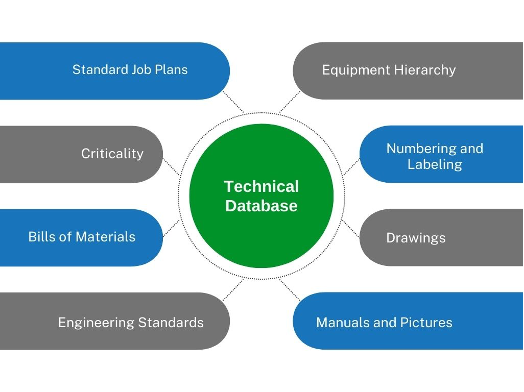

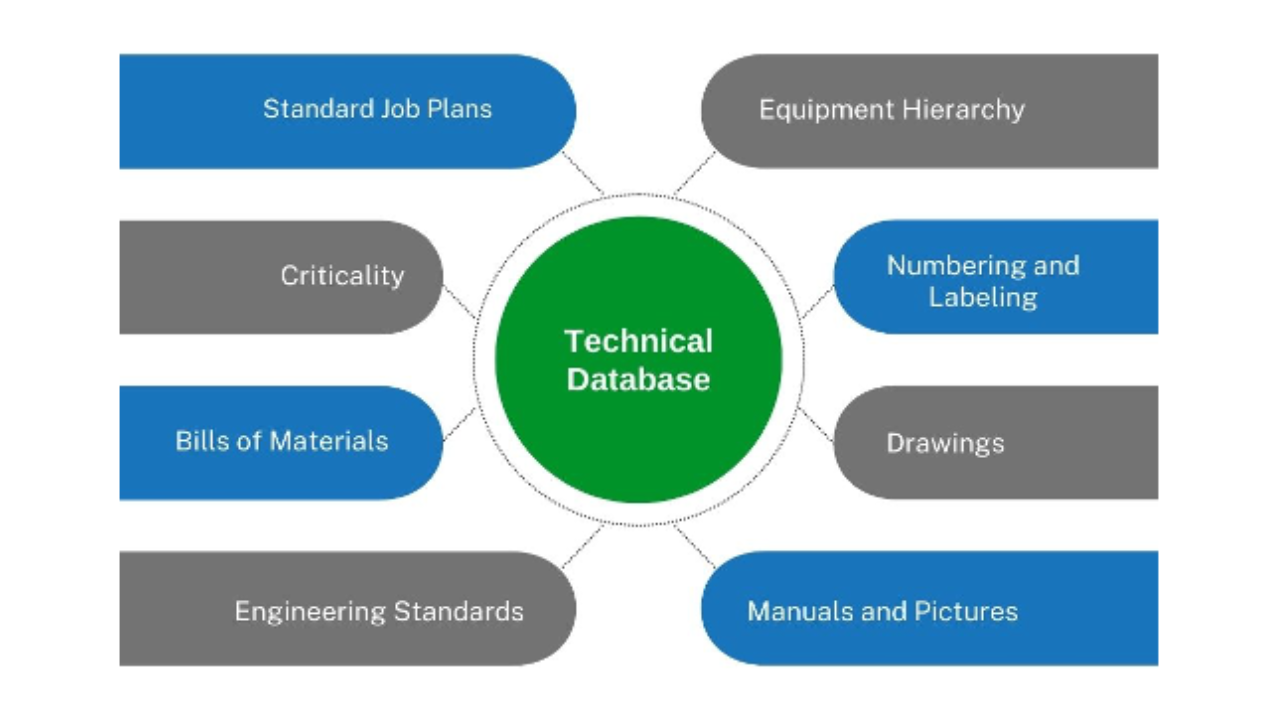

Engineering standards are an element of the technical database and help support the overall planning and scheduling effort.

Accurate, accessible, and applied engineering standards simplify and streamline the planning process. Standards are written procedures that document the methods to be used for the job. Focus standard development on jobs that are both critical and repetitive. Engineering standards are commonly developed for design, fabrication, maintenance prevention, inspection, repair, and installation activities. Standards take an investment of time to develop and maintain but offer potential for huge returns in allowing for simplified planning, better work execution, and lower overall costs of production.

The technical database is made up of eight components, if you’re interested in learning more about each component follow along with the series as it is updated each month.

- Equipment Hierarchy

- Equipment Numbering and Labeling

- Drawings, Manuals, and Pictures

- Engineering Standards

- Bill of Materials

- Criticality

- Standard Job Plans

John Sewell, CMRP

John Sewell, CMRP was a Consultant with IDCON INC from 2020-2025. IDCON is a specialized management consulting firm in the field of reliability and maintenance management. As a consultant, John worked with clients in any industry to improve reliability and lower manufacturing and maintenance costs through hands-on coaching and training.

Related Articles

What is the Technical Database and How Does it Affect Planning and Scheduling?

Practical Guide to Equipment Hierarchy

How to Label and Number Equipment for Easy Identification

Put Your Equipment Drawings, Manuals and Pictures to Work for Cost Savings