Machine Alignment: Alignment Pitfalls – How to Identify and Eliminate Them

Robert D. Skeirik

ALIGNMENT-PITFALLS-HOW-TO-IDENTIFY-AND-ELIMINATE-THEM

Click here to download the full pdf.

Robert D. Skeirik

Related Articles

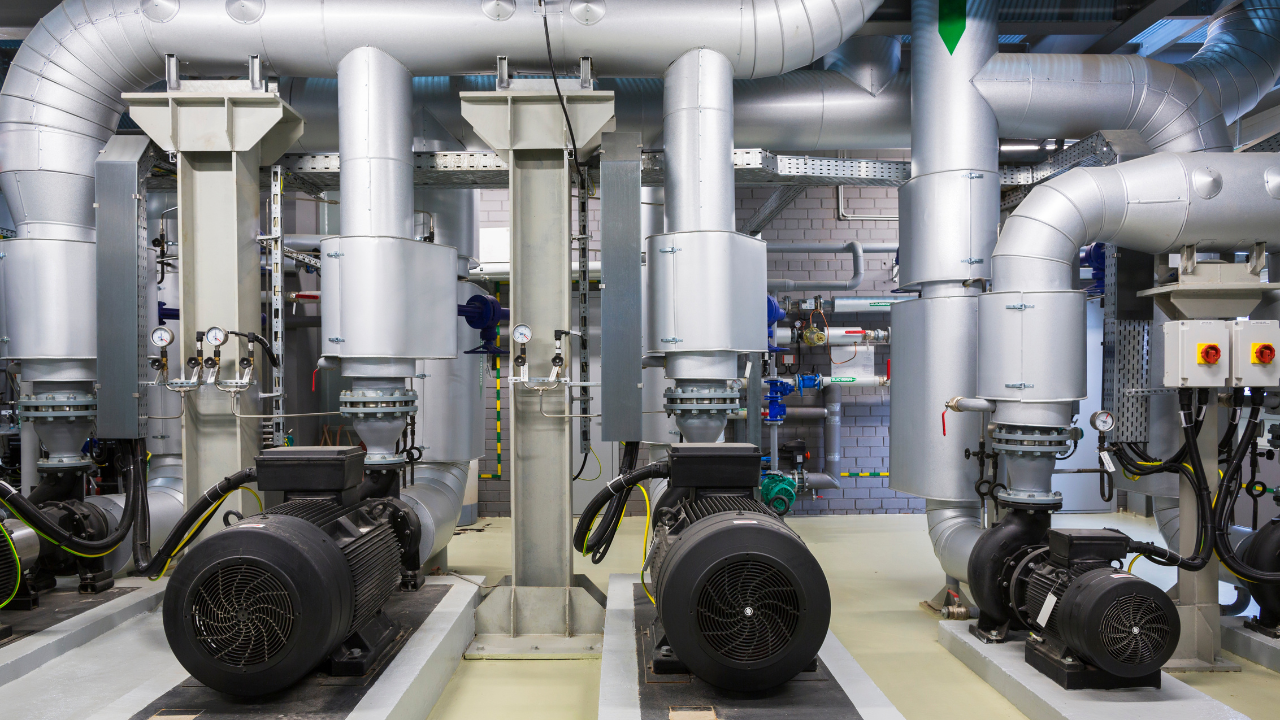

Increasing Pump Reliability and Life

The majority of the failure mechanisms that significantly reduce the reliability and life of a centrifugal pump are caused by operation away from the pump best efficiency point (BEP). To achieve best-in-class life, it is essential to either operate close to the pump BEP (which is always the preferred method) or to provide provisions that anticipate the various effects of off-BEP operation and attempt to mitigate these consequences.

The majority of the failure mechanisms that significantly reduce the reliability and life of a centrifugal pump are caused by operation away from the pump best efficiency point (BEP). To achieve best-in-class life, it is essential to either operate close to the pump BEP (which is always the preferred method) or to provide provisions that anticipate the various effects of off-BEP operation and attempt to mitigate these consequences.

The Most Definitive Test of a Hydraulic Pump

Several tests can be performed on a hydraulic pump to indicate its condition. The temperature of the pump case, the flow of the case drain and the current draw of the drive motor are common checks that can be done regularly and over a period of time to track the wear of a hydraulic pump.

Several tests can be performed on a hydraulic pump to indicate its condition. The temperature of the pump case, the flow of the case drain and the current draw of the drive motor are common checks that can be done regularly and over a period of time to track the wear of a hydraulic pump.

Dynamic Movement White Paper

Regardless of the approach taken to measure true dynamic movement, coupled machines need to be set to cold alignment targets that will reflect the actual changes in the shaft alignment. This will lead to lower vibration levels, increased Mean Time Between Failures, decreased maintenance expenditures and increases in production. Much like the philosophical change from aligning shafts with dial indicators to aligning shafts with laser based systems, these types of measurements will take some time to be generally accepted and routinely practiced.

Regardless of the approach taken to measure true dynamic movement, coupled machines need to be set to cold alignment targets that will reflect the actual changes in the shaft alignment. This will lead to lower vibration levels, increased Mean Time Between Failures, decreased maintenance expenditures and increases in production. Much like the philosophical change from aligning shafts with dial indicators to aligning shafts with laser based systems, these types of measurements will take some time to be generally accepted and routinely practiced.

Costs and Capabilities of Pneumatic, Electric Actuators

Pneumatic or electric? It’s not a new question. The merits of each have long been subject to discussion, but a fair amount of confusion continues to exist about which makes more sense for what. For example, are you considering replacing a compressor and 200 pneumatic cylinders with electric actuators because you think you’ll save on compressor costs? Or, perhaps you are thinking about building a new machine with pneumatics because 30 electric actuators are far too expensive. Make the wrong decision in either case and you could waste tens of thousands of dollars a year.

Pneumatic or electric? It’s not a new question. The merits of each have long been subject to discussion, but a fair amount of confusion continues to exist about which makes more sense for what. For example, are you considering replacing a compressor and 200 pneumatic cylinders with electric actuators because you think you’ll save on compressor costs? Or, perhaps you are thinking about building a new machine with pneumatics because 30 electric actuators are far too expensive. Make the wrong decision in either case and you could waste tens of thousands of dollars a year.

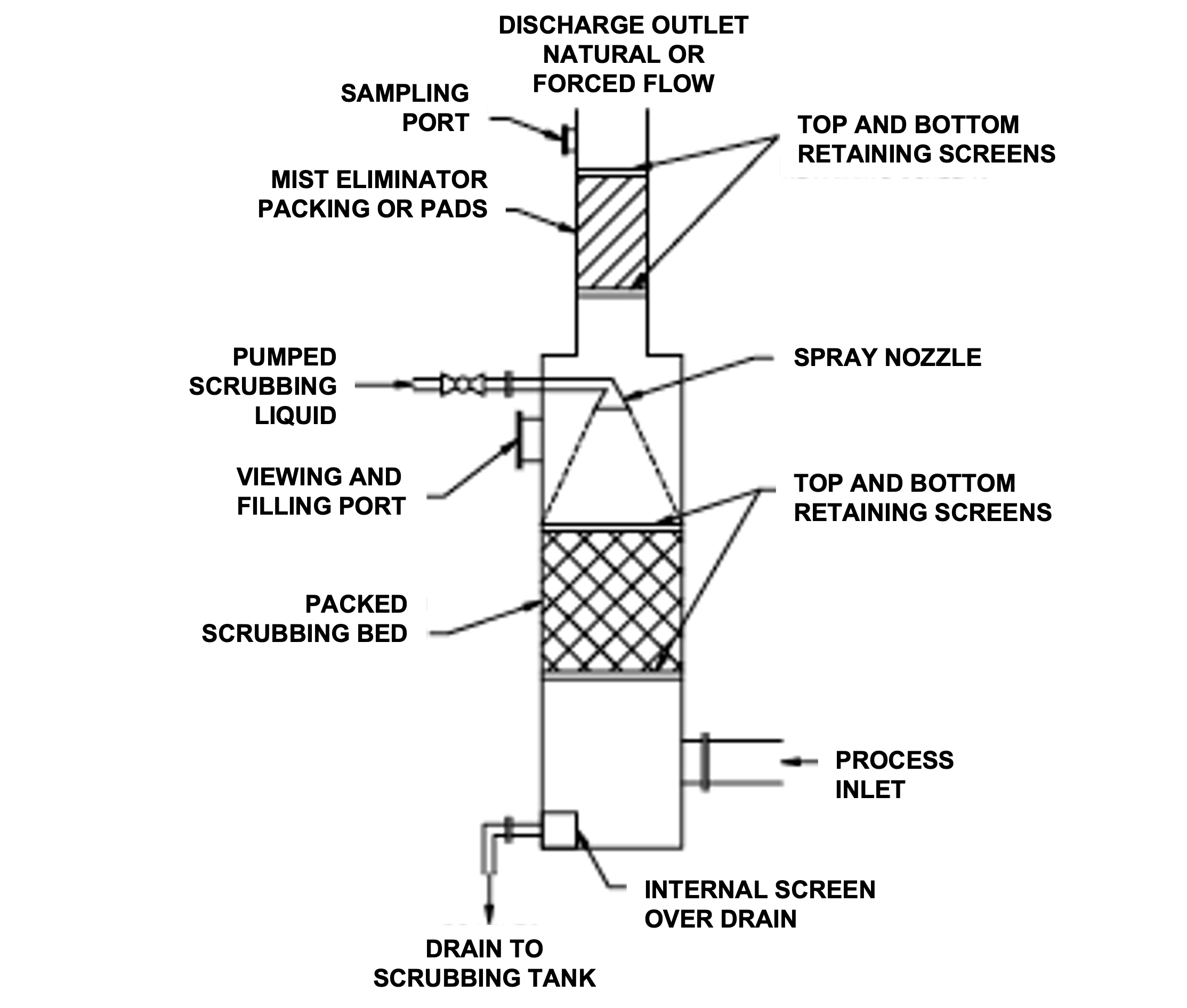

Is Your Wet Scrubbing Tower Working?

Is your scrubbing tower working? A wet scrubbing tower is used to clean odors, particles, mists, and vapors from a gas stream. The gas is forced through the tower. As it moves from inlet to outlet it is washed and cleaned. The washing is done with suitable chemicals that remove the active components in the gas flow. The gas is cleaned to environmentally acceptable levels and discharged to atmosphere.

Is your scrubbing tower working? A wet scrubbing tower is used to clean odors, particles, mists, and vapors from a gas stream. The gas is forced through the tower. As it moves from inlet to outlet it is washed and cleaned. The washing is done with suitable chemicals that remove the active components in the gas flow. The gas is cleaned to environmentally acceptable levels and discharged to atmosphere.

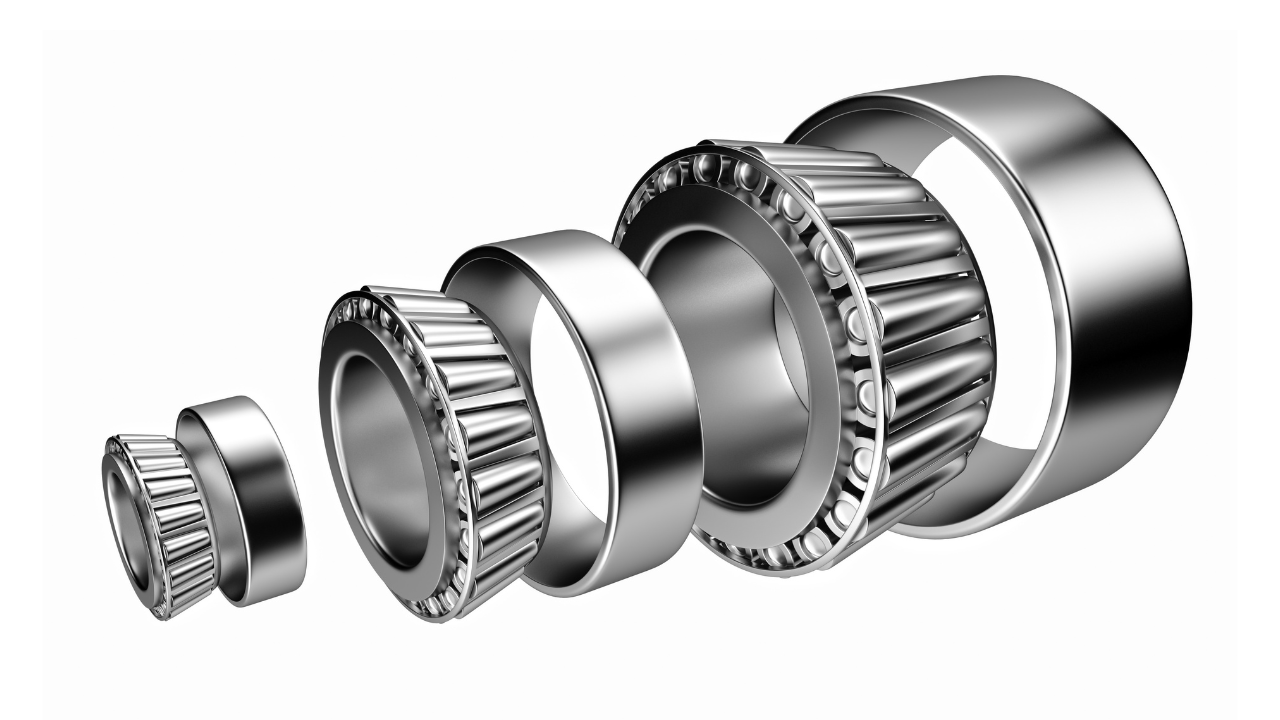

Setting Techniques for Tapered Roller Bearings

Tapered roller bearings can be set at initial machine assembly to any desired axial or radial clearance. This unique feature enables a designer to control bearings to meet anticipated application operating conditions, and thereby provide optimum bearing and system performance. Some advantages of tapered roller bearings pertaining to setting include...

Tapered roller bearings can be set at initial machine assembly to any desired axial or radial clearance. This unique feature enables a designer to control bearings to meet anticipated application operating conditions, and thereby provide optimum bearing and system performance. Some advantages of tapered roller bearings pertaining to setting include...