AI-Driven Interactive Tools for Maintenance

Ahmed Rezika, SimpleWays OU

Posted 12/4/2025

“Introducing new technologies into the core of a business can fundamentally change the skills that employees will need on a day-to-day basis. Organizations should direct resources to upskill those workers and make them feel comfortable with the new tech. McKinsey analysis has found that the top barrier to implementing growth strategies, especially those related to digitalization, is talent.” Mckinsey [1]

The Dashboard Origins

The term “dashboard” traces back to 1847, originally describing a wooden or leather barrier at the front of horse-drawn carriages designed to protect drivers from mud “dashed up” by horses’ hooves [2]. When the first automobiles appeared in the late 1800s, this protective panel found new purpose—shielding occupants from engine heat, oil, and debris kicked up by wheels. As engines moved to the front of vehicles in the early 1900s, manufacturers discovered the dashboard was the ideal location for mounting controls and gauges, transforming it from a simple barrier into an information center.

Early dashboards displayed only essentials: a speedometer, perhaps an ammeter, and if you were lucky, a fuel gauge. By the 1940s and 50s, influenced by World War II bomber cockpits, dashboards became elaborate arrays of dials and chrome-trimmed instrumentation—more aesthetic statement than functional necessity. The digital revolution arrived in 1976 with the Aston Martin Lagonda’s electronic instrument cluster, featuring LED displays and touch controls that would have looked at home in a science fiction film.

Fast forward to 2025, and the automotive dashboard has become something unrecognizable to early motorists. Today’s vehicle dashboards feature AI-powered systems that recognize individual drivers and automatically adjust settings, monitor driver vital signs and behavior patterns, and integrate seamlessly with smartphones through voice-activated personal assistants. BMW’s iDrive X/Panoramic Vision platform showcased at CES 2025 uses the entire windshield as a heads-up display, projecting navigation, warnings, and vehicle data transparently across the driver’s field of view These aren’t just dashboards anymore—they’re predictive, adaptive, conversational interfaces.

Modern vehicles can forecast maintenance needs using AI analysis of sensor data, automatically adjust suspension based on road conditions and driving style, and communicate vehicle-to-vehicle to prevent collisions before drivers even perceive the threat. The dashboard evolved from protecting you from mud to protecting you from accidents you haven’t seen yet.

How is maintenance relatable to the dashboard evolution?

This automotive evolution mirrors—and in many ways pioneered—what’s happening in industrial and operational dashboards today. Manufacturing dashboards in 2025 integrate real-time IoT sensor data with predictive analytics, with manufacturers reporting 20% improvements in overall equipment effectiveness (OEE) and 25% reductions in machine downtime through smart monitoring systems. Just as modern car dashboards transitioned from analog dials to digital clusters with customizable views, industrial dashboards now offer role-specific interfaces: operators see machine status and job progress on shop floor displays, supervisors track performance bottlenecks, and executives access strategic KPIs from anywhere.

The manufacturing sector is now investing heavily in agentic AI systems i.e. a group of AI Agents working together for a common goal. “That’s because agents have the potential to automate complex business processes—combining autonomy, planning, memory, and integration—to shift gen AI from a reactive tool to a proactive, goal-driven virtual collaborator.” McKinsey[5]

The target or the hopes in the Agentic AI framework focus on the possibility that it can autonomously identify alternative suppliers during disruptions, capture institutional knowledge from retiring workers, and generate shift handover reports without human intervention.

The parallel is striking—both automotive and industrial dashboards have shifted from passive displays of historical or current data to active, intelligent systems that anticipate needs, suggest actions, and increasingly make autonomous decisions. What started as protection from horse-kicked mud has become the neural interface between humans and complex systems, whether those systems have four wheels or forty production lines. Let’s delve deeper into this parallel to understand what is coming next in the maintenance realm.

What’s Actually New? Rule-Based Intelligence vs. Learning Systems

Before we celebrate the “AI revolution,” we need an honest reckoning: much of what vehicles have been doing for decades isn’t the kind of AI that’s reshaping maintenance today—it’s rule-based automation dressed in new buzzword clothing. Adaptive suspension systems have existed since 1983 when Toyota’s TEMS electronically controlled shock absorbers, with Mercedes introducing hydropneumatic systems with adaptive damping in 1986.

These systems use sensors to measure steering input, road surface roughness, wheel speed, and vehicle acceleration, with Electronic Control Units processing sensor data through adaptive algorithms to make rapid decisions about suspension modifications. But here’s the critical distinction: rule-based systems rely on predefined business rules manually programmed by human experts using if-then statements.

Whereas machine learning/AI systems automatically train themselves to identify patterns from data without explicit programming. Rule-based systems are deterministic and operate on simple cause-and-effect methodology, structured to perform only the tasks they’ve been programmed for. Even the Vehicle-to-vehicle collision prevention using pre-programmed safety zones and braking distances started as rule-based automation, no matter how impressive it looked.

What made the shift?

The genuinely transformative shift—the one that actually deserves the AI label—is the move to learning systems that discover patterns humans never explicitly programmed. Recent active suspension research employs deep reinforcement learning methods where algorithms train agents without prior knowledge of the environment, allowing systems to adapt to any environment and continuously improve ride comfort [3] [4].

Modern mechanism-data-driven control strategies integrate differential geometry with deep reinforcement learning to achieve theoretical fusion of mechanism and data models, addressing the complexity of vehicle parameters, variability of road conditions, and uncertainty of external interference that model-based methods struggle to handle.

The difference is profound: traditional adaptive suspension followed rules engineers encoded about what “good handling” means; while modern learning-based systems discover optimal suspension responses by trying millions of scenarios in simulation, finding control strategies human engineers never imagined. Machine learning models use a probabilistic approach that takes into account variations and probabilities to create informed results, automatically learning from data without human intervention to define their own set of rules. Moreover, they store this analysis based on the GPS location for future use and creating based models for other cars.

How this is relatable to maintenance and dashboards?

This same distinction applies directly to maintenance dashboards, and it’s crucial for understanding what’s genuinely new versus what’s rebranded legacy automation. The CMMS dashboard that triggers a work order when bearing temperature exceeds 85°C? That’s rule-based—someone programmed that threshold. Rule-based systems don’t scale or adapt well, require manual intervention for any updates, can’t learn or evolve on their own, and operate only within predefined logic without ability to infer or extrapolate.

The system that analyzes vibration patterns across ten thousand similar bearings globally, discovers that a specific frequency signature combined with load profile predicts failure 72 hours in advance—even though no engineer explicitly programmed that correlation? That’s machine learning. Machine learning systems can adapt to changing data patterns, automatically improving their performance as they learn from new information, and excel at automating complex tasks while continuously learning and optimizing performance over time

The conversational interface that lets you ask “Why is my reliability index dropping?” and receives an answer synthesized from sensor trends, maintenance histories, production schedules, and supply chain disruptions—connecting dots no human explicitly taught it to connect? That’s the Large Language Model revolution that truly changes how maintenance professionals interact with their systems.

So yes, much of what’s marketed as “AI-powered” today is just yesterday’s automation with a fresh coat of buzzword paint. But the learning systems—the ones that discover patterns, adapt continuously to the context, and converse naturally—represent something genuinely new, and that’s where the transformation of maintenance dashboards becomes real rather than rhetorical.

What is now perceived publicly as AI is actually the generative AI. The next wave will call this as Agentic AI which takes decisions not merely advice as per Mckinsey forecast: “That’s because agents have the potential to automate complex business processes—combining autonomy, planning, memory, and integration—to shift gen AI from a reactive tool to a proactive, goal-driven virtual collaborator.” [5]

The Connectivity Revolution: From Simple Wires to Intelligent Networks

To create and integrate an AI-powered interactive dashboard accessible on every device with secure login, here is a detailed technical explanation broken into clear parts:

1. What is Behind the Dashboard (Technical Architecture)?

An AI dashboard typically involves these core components:

- Data Layer: Centralized storage like data lakes or warehouses hold structured, semi-structured, and unstructured data. Data can come from multiple sources—databases, APIs, IoT sensors, CSV files, etc.

- Data Integration and ETL: Data pipelines extract, transform, and load data into the storage, ensuring cleanliness and consistency. Automated data quality checks and lineage tracking ensure reliable data.

- AI/ML Processing Layer: Machine learning models run on the integrated data to generate predictive and prescriptive analytics. This includes anomaly detection, forecasting, and recommendations.

- API Layer: Provides programmatic access to data, analytics results, and dashboard functionality—key for integration and interoperability. [6]

- User Interface Layer: The interactive dashboard UI displays visualizations and receives user input. AI capabilities here include natural language querying and autonomous insight generation (e.g., an analytics chatbot).

- Security and Governance: Authentication, authorization, data encryption, secure API access, and compliance mechanisms ensure the dashboard and data are protected.

Tools like Sisense, Microsoft Azure AI, or custom-built solutions adopt composable SDKs and APIs enabling flexible dashboard composition with AI components embedded deeply.

2. Preparing Your Data for Integration

- Identify Data Sources: List all data repositories—databases, APIs, spreadsheets, or IoT devices.

- Clean and Normalize Data: Use ETL or ELT tools to transform varied raw data into a consistent format.

- Schema Definition and Validation: Define data schemas (e.g., using JSON Schema or Pydantic in Python) to validate incoming data to prevent errors downstream.

- Data Update and Sync Mechanisms: Set intervals for real-time or batch updates, depending on use-case urgency.

- Data Access APIs: Make sure data endpoints support secure, reliable, and fast API access for dashboard queries.

3. Connecting or Plugging Your Data into the Dashboard

- Choose or develop dashboards supporting data connectors to your data sources (e.g., Google Sheets, SQL, REST APIs).

- Use SDKs or API clients to fetch data into the dashboard platform.

- Implement queries or scripts (possibly with Google Apps Script for Google Sheets) to pull or push data dynamically.

- Configure AI models either by embedding pre-trained services or training custom models on your data, ensuring outputs feed visual components.

- Use webhook or event-driven triggers for real-time dashboard refreshes.

4. Making the Dashboard Available on Every Device

- Responsive Web Design: Dashboard frontends should be built with responsive frameworks (React, Angular, Vue.js) that adapt UI elements for mobiles, tablets, and desktops.

- Mobile Apps: Native or hybrid mobile apps (Android/iOS) can embed dashboards or provide API access wrapped in a mobile UI.

- Cloud Hosting: Host dashboards in the cloud (AWS, Azure, Google Cloud) to ensure global availability and scalability.

- User Authentication and Single Sign-On (SSO): Integrate with identity providers (OAuth, SAML, OpenID Connect) allowing users to log in securely from any device.

- Session Management: Maintain secure user sessions with token-based authentication (JWT) and automatic session expiration.

- Progressive Web Apps (PWAs): Enable offline access and device-friendly UI without requiring app store downloads.

5. Security Measures

- Authentication and Authorization: Enforce strong user identity verification and role-based access control to limit data visibility according to permissions.

- Data Encryption: Secure data in transit (TLS/SSL) and at rest (AES encryption) to protect sensitive information.

- API Security: Use rate limiting, API keys, and scopes to secure data endpoints.

- Audit Trails and Monitoring: Maintain logs of user access and actions for compliance and anomaly detection.

- Compliance: Align with GDPR, HIPAA, or industry-specific data protection standards.

- Regular Penetration Testing and Updates: Continuously test for vulnerabilities and keep the software stack patched.

In essence, to build a technical AI-powered dashboard solution accessible everywhere, you need a well-architected system beginning with reliable data ingestion, AI analytics, secure APIs, a responsive or mobile-friendly UI, and strong security protocols.

This structure allows maintenance teams to interact with real-time insights securely from any device, leveraging AI to enhance decision-making and communication protocols like MCP [10].

Automobile Dashboard Connectivity

The automotive dashboard’s data connectivity journey began in earnest with the 1996 mandate requiring all U.S. vehicles to include standardized On-Board Diagnostics II (OBD-II) ports for emissions monitoring and diagnostics. Before OBD-II, mechanics faced a bewildering array of proprietary connectors and protocols across manufacturers—imagine trying to diagnose fifty different production lines, each speaking its own language. OBD-II standardized everything around a 16-pin connector located under the steering wheel, establishing a common protocol for extracting diagnostic trouble codes and real-time performance data.

By 2008, the transition was complete: all vehicles were required to support OBD-II functionality using Controller Area Network (CAN bus) protocols, enabling faster data retrieval through pins 6 and 14 on the diagnostic port. The CAN bus architecture was revolutionary—instead of running dedicated wires from every sensor to the dashboard (imagine the weight and complexity!), CAN allowed multiple Electronic Control Units (ECUs) to broadcast messages on just two twisted wires, with each recipient deciding which messages mattered to them. This was industrial networking before most factories had it.

The parallel evolution in maintenance systems followed a remarkably similar trajectory, though often years behind automotive innovation. CMMS integration began connecting maintenance platforms with IoT devices, ERP solutions, and SCADA (Supervisory Control and Data Acquisition) systems through APIs, cloud services, and edge devices. However, the industrial world faced a critical challenge: operations controlled SCADA systems tightly, making it difficult for maintenance teams to access sensor data, and building custom interfaces required IT expertise that was rarely available or properly prioritized. The data was there—temperature sensors on bearings, pressure transducers on hydraulic systems, vibration monitors on rotating equipment—but traditional SCADA systems used proprietary protocols, mainframe computers, and remote terminal units designed for on-premise data collection and real-time control, with limited data storage and analysis capabilities beyond immediate operational needs.

The connectivity transformation in both domains follows the same arc: from proprietary islands of data to standardized protocols, from wired point-to-point connections to networked bus architectures, and from manual interpretation to automated intelligence. Whether it’s a car predicting when its oil needs changing or a production line forecasting bearing failure three days in advance, the underlying connectivity infrastructure—those seemingly mundane standards like CAN bus, Modbus, OPC-UA, and BACnet—made the AI revolution in dashboards possible. You can’t have intelligent insights without intelligent connectivity first. How this affects maintenance teams, that’s what are going to see next

Conclusion: Dashboards, The Intelligent Partners

The dashboard’s journey—from a literal wooden barrier protecting carriage drivers from horse-kicked mud to today’s conversational AI interfaces—mirrors the fundamental transformation happening in maintenance management. We’ve traced this evolution through standardized connectivity (OBD-II and CAN bus in automotive, IoT and API integration in industrial settings), through the democratization of data access that broke down walls between production and maintenance teams, and finally to the genuine paradigm shift: from rule-based automation executing preprogrammed instructions to learning systems that discover patterns, adapt continuously, and converse naturally. The dashboards our industry relied on for decades were reactive reporters of what happened; today’s AI-driven interactive tools are proactive partners anticipating what’s about to happen and guiding us through solving it.

But the real transformation isn’t technological—it’s human. Just as automotive technicians evolved from wrench-turners to diagnostic specialists fluent in software and sensor networks, industrial maintenance professionals must now master both the physical and digital domains. And the organizations that recognize this shift— will invest in hybrid maintenance professionals who command both wrench and algorithm, both bearing replacement and data interpretation—will be the ones whose equipment runs reliably, efficiently, and predictably while their competitors are still figuring out which dashboard to click. That’s why we need a dedicated article for this topic

Must-Know Jargon

OBD-II (On-Board Diagnostics II) Standardized vehicle diagnostic protocol mandated in U.S. vehicles since 1996. Uses a 16-pin connector to retrieve diagnostic trouble codes and real-time performance data from electronic control units.

CAN Bus (Controller Area Network) Multi-master serial bus protocol allowing electronic control units to communicate on two twisted wires. Supports data rates from 125 kbps to 1 Mbps, eliminating point-to-point wiring between components.

CMMS (Computerized Maintenance Management System) Software platform managing work orders, asset histories, preventive maintenance schedules, and spare parts inventory. Modern systems integrate with IoT sensors and ERP platforms via APIs.

SCADA (Supervisory Control and Data Acquisition) Industrial control system for real-time monitoring and control of processes across distributed facilities. Uses remote terminal units and programmable logic controllers to collect and transmit operational data.

Data Schema Logical structure defining how data is organized, stored, and related within a database or system. Specifies tables, fields, data types, relationships, and constraints that govern data integrity and access patterns.

Data Integration Process of combining data from disparate sources into unified, accessible views or repositories. Involves ETL (Extract, Transform, Load) processes, API connections, and middleware to synchronize data across CMMS, ERP, SCADA, and IoT platforms.

Cloud Hosting Deployment of applications and data storage on remote servers accessed via internet rather than on-premises infrastructure. Enables scalable computing resources, automatic updates, and multi-site accessibility without local server maintenance.

References

1- McKinsey & Co, September 16, 2025 | Article, Remapping travel with agentic AI, https://www.mckinsey.com/industries/travel/our-insights/remapping-travel-with-agentic-ai

2- PIRELLI , July 03, 2024, The dashboard: a continuous evolution of information, https://www.pirelli.com/global/en-ww/road/cars/the-dashboard-a-continuous-evolution-of-information-121663/

3-SSRN, Lich Duc Luu et al. Apr 12, 2023 A New Approach to Active Suspension Control in Cars Based on Deep Reinforcement Learning, https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5214876

4- AutoTimesNews, BMWGrup, BMW Adaptive M Suspension: How It’s Evolved In 2025 Models, https://autotimesnews.com/bmw-adaptive-m-suspension-how-its-evolved-in-2025-models/ , https://www.press.bmwgroup.com/global/article/detail/T0445514EN/the-new-bmw-2-series-gran-coup%C3%A9?language=en

5-McKnsey & CO, November 23, 2025, 5 McKinsey insights on how agentic AI is reshaping industries, https://www.mckinsey.com/featured-insights/themes/5-mckinsey-insights-on-how-agentic-ai-is-reshaping-industries

6-MaintenanceWorld Magazine, Ahmed Rezika, July 3, 2025, Gluing the Dissected: API-Orchestration mimics Maintenance Flow, https://maintenanceworld.com/2025/07/03/gluing-the-dissected-api-orchestration-mimics-maintenance-flow/

Ahmed Rezika

Ahmed Rezika is a seasoned Projects and Maintenance Manager with over 25 years of hands-on experience across steel, cement, and food industries. A certified PMP, MMP, and CMRP(2016-2024) professional, he has successfully led both greenfield and upgrade projects while implementing innovative maintenance strategies.

As the founder of SimpleWays OU, Ahmed is dedicated to creating better-managed, value-adding work environments and making AI and digital technologies accessible to maintenance teams. His mission is to empower maintenance professionals through training and coaching, helping organizations build more effective and sustainable maintenance practices.

Related Articles

Longer Lasting Lubricants for The Aluminum Industry

Why Condition Based Maintenance Should Be Considered a Critical Component of Any Business’s Asset Maintenance Strategy

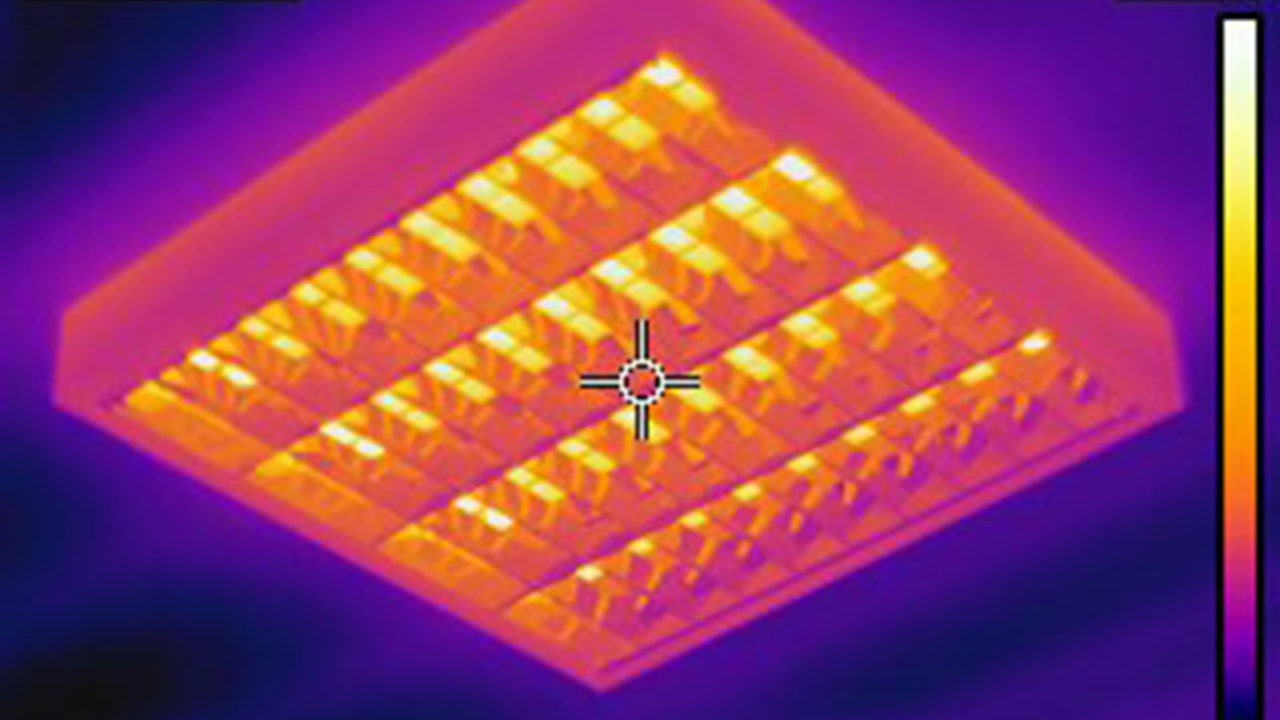

The Effectiveness Equation for Infrared Predictive Maintenance Programs

Define and Measure KPIs and Goals for Condition Based Maintenance

An Introduction to Machine Vibration