Troubleshooting Mechanical Seals | Scoring | Part 5

Chesterton

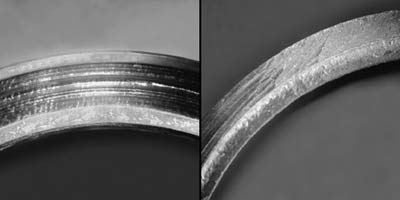

Scoring

| SEAL FACE SCORING | SEAL FACE EROSION |

SYMPTOMS:

- Scoring or erosion

CAUSES:

- Rebuilding seal in dirty environment

- Faces opening/flashing/vibration/distortion of the seal face due to temperature and pressure

- Minerals found in the fluid film between the seal faces

FAILURE MODES:

- Abrasive particles between the seal faces

- Lack of seal face lubrication

SOLUTIONS:

- Maintain seal face flatness

- Eliminate dry running, flashing and vibration

- Use clean flush source with bushingUse suction recirculation control

- Use harder seal face materials

Related Articles

Causes of Overheating in Cartridge Mechanical Seals

Too much heat can cause multiple problems with cartridge mechanical seals. Some heat problems are not seal design or seal installation related.

Too much heat can cause multiple problems with cartridge mechanical seals. Some heat problems are not seal design or seal installation related.

How Can I Extend the Performance Range of Standard Cartridge Mechanical Seals?

In today's global environment, the "one size fits all" approach is used for so many products that we expect it to apply to just about everything. In the mechanical seal industry, one problem with that philosophy is the definition of the word all. Mechanical seals must live in literally every environment under the sun-from extreme hot to extreme cold, wet to dry, solid to gas, acidic to caustic and so on. Until relatively recently, a vast variety of cartridge mechanical seals were needed to accommodate these pump applications.

In today's global environment, the "one size fits all" approach is used for so many products that we expect it to apply to just about everything. In the mechanical seal industry, one problem with that philosophy is the definition of the word all. Mechanical seals must live in literally every environment under the sun-from extreme hot to extreme cold, wet to dry, solid to gas, acidic to caustic and so on. Until relatively recently, a vast variety of cartridge mechanical seals were needed to accommodate these pump applications.

The Process of Troubleshooting Mechanical Seals - Part 1

The 9 articles in this series will outline common issues with mechanical seals, how to notice them, and troubleshooting tips. The series addresses: wide wear track, centered/miscentered, even/uneven wear track, scoring, chipping, coking, heat cracking or checking, and blistering.

The 9 articles in this series will outline common issues with mechanical seals, how to notice them, and troubleshooting tips. The series addresses: wide wear track, centered/miscentered, even/uneven wear track, scoring, chipping, coking, heat cracking or checking, and blistering.

Troubleshooting Mechanical Seals | Wide Wear Track | Part 2

Part 2 of 9 on Troubleshooting Mechanical Seals: Wide Wear Track - symptoms, causes, failure modes, and solutions.

Part 2 of 9 on Troubleshooting Mechanical Seals: Wide Wear Track - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Centered/ Miscentered | Part 3

Part 3 of 9 on Troubleshooting Mechanical Seals: Centered/Miscentered - symptoms, causes, failure modes, and solutions.

Part 3 of 9 on Troubleshooting Mechanical Seals: Centered/Miscentered - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Even/Uneven Wear Track | Part 4

Part 4 of 9 on Troubleshooting Mechanical Seals: Even/Uneven Wear Track - symptoms, causes, failure modes, and solutions.

Part 4 of 9 on Troubleshooting Mechanical Seals: Even/Uneven Wear Track - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Chipping | Part 6

Part 6 of 9 on Troubleshooting Mechanical Seals: Chipping - symptoms, causes, failure modes, and solutions.

Part 6 of 9 on Troubleshooting Mechanical Seals: Chipping - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Coking | Part 7

Part 7 of 9 on Troubleshooting Mechanical Seals: Coking or Crystallized - symptoms, causes, failure modes, and solutions.

Part 7 of 9 on Troubleshooting Mechanical Seals: Coking or Crystallized - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Heat Checking or Cracking | Part 8

Part 8 of 9 on Troubleshooting Mechanical Seals: Heat Cracking or Heat Checking - symptoms, causes, failure modes, and solutions.

Part 8 of 9 on Troubleshooting Mechanical Seals: Heat Cracking or Heat Checking - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Mechanical Seal Blistering | Part 9

Part 9 of 9 on Troubleshooting Mechanical Seals: Mechanical Seal Blistering - symptoms, causes, failure modes, and solutions.

Part 9 of 9 on Troubleshooting Mechanical Seals: Mechanical Seal Blistering - symptoms, causes, failure modes, and solutions.

How Do Variable Speed Drives Impact Mechanical Seals?

Whether the mismatch was due to the variation in required pump output or incorrect sizing of the pump, there is no question that the ability to easily vary pump speed has been a major advance in the overall performance of a pumping system. This has increased the energy efficiency, as well as the reliability of the equipment. Problems—such as cavitation or shaft deflection—can be alleviated by running the pump at optimal system speed. But how do variable speed drives affect mechanical seals?

Whether the mismatch was due to the variation in required pump output or incorrect sizing of the pump, there is no question that the ability to easily vary pump speed has been a major advance in the overall performance of a pumping system. This has increased the energy efficiency, as well as the reliability of the equipment. Problems—such as cavitation or shaft deflection—can be alleviated by running the pump at optimal system speed. But how do variable speed drives affect mechanical seals?