Hydraulic Systems Safety

Paul D. Ayers, Colorado State University

Quick Facts About Hydraulic Systems Safety…

Hydraulic systems must store fluid under high pressure. Three kinds of hazards exist: burns from the hot, high-pressure spray of fluid; bruises, cuts, or abrasions from flailing hydraulic lines; and injection of fluid into the skin. Hydraulic systems safety and performance requires general maintenance. Proper coupling of high and low-pressure hydraulic components and pressure relief valves are important safety measures.

Hydraulic systems are popular on many types of agricultural equipment because they reduce the need for complex mechanical linkages and allow remote control of numerous operations. Hydraulic systems are used to lift implements, such as plows; to change the position of implement components, such as a combine header or bulldozer blade; to operate remote hydraulic motors; and to assist steering and braking.

To do their work, hydraulic systems must store fluid under high pressure, typically 2,000 pounds or more per square inch. One hazard comes from removing or adjusting components without releasing the pressure. The fluid, under tremendous pressure, is also hot. The worker then is exposed to three kinds of hazards: burns from hot, high-pressure fluid; bruises, cuts or abrasions from flailing hydraulic lines; and injection of fluid into the skin.

Many systems store hydraulic energy in accumulators. These accumulators are designed to store oil under pressure when the hydraulic pump cannot keep up with demand, when the engine is shut down, or when the hydraulic pump malfunctions. Even though the pump may be stopped or an implement disconnected, the system is still under pressure. To work on the system safely, relieve the pressure first.

Pinhole Leak Injuries

Probably the most common injury associated with hydraulic systems is the result of pinhole leaks in hoses. These leaks are difficult to locate. A person may notice a damp, oily, dirty place near a hydraulic line. Not seeing the leak, the person runs a hand or finger along the line to find it. When the pinhole is reached, the fluid can be injected into the skin as if from a hypodermic syringe.

Immediately after the injection, the person experiences only a slight stinging sensation and may not think much about it. Several hours later, however, the wound begins to throb and severe pain begins. By the time a doctor is seen, it is often too late, and the individual loses a finger or entire arm.

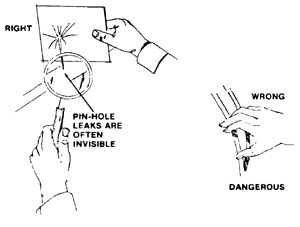

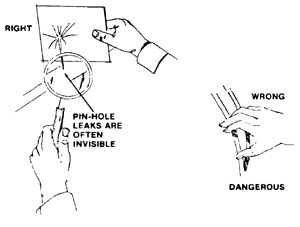

Unfortunately, this kind of accident is not uncommon. To reduce the chances of this type of injury, run a piece of wood or cardboard along the hose (rather than fingers) to detect the leak (see Figure 1).

Figure 1: Detecting pinhole leaks in a hydraulic system.

Improper Coupling

Another hazard is improper coupling of low- and high-pressure hydraulic components. Do not connect a high-pressure pump to a low-pressure system. Do not incorporate a low-pressure component, hose or fitting into a high-pressure system. Component, hose or fitting ruptures are likely to occur.

Pressure relief valves incorporated into the hydraulic system will avoid pressure buildups during use. Keep these valves clean and test them periodically to ensure correct operation.

Maintenance

An improperly maintained hydraulic system can lead to component failures. Safe hydraulic system performance requires general maintenance.

- Periodically check for oil leaks and worn hoses.

- Keep contaminants from hydraulic oil and replace filters periodically.

- Coat cylinder rods with protective lubricants to avoid rusting.

Tips for Safe Operation

Follow these rules for safe hydraulics operation:

- Always lower the hydraulic working units to the ground before leaving the machine.

- Park the machinery where children cannot reach it.

- Block up the working units when you must work on the system while raised; do not rely on the hydraulic lift.

- Never service the hydraulic system while the machine engine is running unless absolutely necessary (bleeding the system).

- Do not remove cylinders until the working units are resting on the ground or securely on safety stands or blocks; shut off the engine.

- When transporting the machine, lock the cylinder stops to hold the working units solidly in place.

- Before disconnecting oil lines, relieve all hydraulic pressure and discharge the accumulator (if used).

- Be sure all line connections are tight and lines are not damaged; escaping oil under pressure is a fire hazard and can cause personal injury.

- Some hydraulic pumps and control valves are heavy. Before removing them, provide a means of support such as a chain hoist, floor jack or blocks.

- When washing parts, use a nonvolatile cleaning solvent.

- To ensure control of the unit, keep the hydraulics in proper adjustment.

For more information read this Hydraulic System preventative maintenance checklist.

Download the full pdf.

Paul D. Ayers, Colorado State University

Related Articles

Certified mail has arrived. The letter carrier isn't Ed McMahon. Uh Oh! It's a citation package from the USDOL/OSHA. What do you do? You glance at the paperwork to be sure it really relates to an OSHA inspection at one of your sites. You notice some rather heavy penalties. You are shocked, irate and feel as if you've been branded "corporate slime." You try to convince yourself that you've been in lots of workplaces that are more dangerous than yours. You need this like a centipede needs sore feet. Options pop through you mind.

Certified mail has arrived. The letter carrier isn't Ed McMahon. Uh Oh! It's a citation package from the USDOL/OSHA. What do you do? You glance at the paperwork to be sure it really relates to an OSHA inspection at one of your sites. You notice some rather heavy penalties. You are shocked, irate and feel as if you've been branded "corporate slime." You try to convince yourself that you've been in lots of workplaces that are more dangerous than yours. You need this like a centipede needs sore feet. Options pop through you mind.

See More

In 2001, close to 100,000 people were treated in U.S. Hospital emergency rooms for eye injuries related to the workplace, yet this figure actually only represents a small portion of the total number of injuries. According to the U.S. Bureau of Labor Statistics, each day, as many as 2,000 workers incur eye injuries related to their jobs. According to Prevent Blindness America (PBA), 90% of these injuries are preventable.

In 2001, close to 100,000 people were treated in U.S. Hospital emergency rooms for eye injuries related to the workplace, yet this figure actually only represents a small portion of the total number of injuries. According to the U.S. Bureau of Labor Statistics, each day, as many as 2,000 workers incur eye injuries related to their jobs. According to Prevent Blindness America (PBA), 90% of these injuries are preventable.

See More

With literally thousands of dangerous materials being used/transported/discarded every day, the process of choosing protective clothing has become increasingly complex for today's safety and hygiene professional. It is important to understand the distinction between three broad types of protective garments used today. Generally classified as disposable, reusable, and limited-use garments, these three general categories provide a basic framework for clothing decisions.

With literally thousands of dangerous materials being used/transported/discarded every day, the process of choosing protective clothing has become increasingly complex for today's safety and hygiene professional. It is important to understand the distinction between three broad types of protective garments used today. Generally classified as disposable, reusable, and limited-use garments, these three general categories provide a basic framework for clothing decisions.

See More

“Prevention is better than cure”, this proverb sounds rightly in case of maintenance also. If the maintenance is prevented, then the availability of the plant increases and the overall cost reduces. Every effort should be made to avoid maintenance, which can be achieved through continuous monitoring of equipment and upgrading the sophistication of the equipment through better design and process improvement.

“Prevention is better than cure”, this proverb sounds rightly in case of maintenance also. If the maintenance is prevented, then the availability of the plant increases and the overall cost reduces. Every effort should be made to avoid maintenance, which can be achieved through continuous monitoring of equipment and upgrading the sophistication of the equipment through better design and process improvement.

See More

When we have catastrophic events such as the club fire in RI, the inspection process that allowed code violations to go uncorrected for two years needs to be revisited. Many inspectors view their daily work in a way that results in the low hanging fruit getting picked, but the more difficult to reach fruit on high branches going untouched. When an agency is responsible for inspections for compliance with safety, health, fire and/or environmental standards there needs to be a meaningful quality control or improvement program in place. Citizens or your community deserve no less.

When we have catastrophic events such as the club fire in RI, the inspection process that allowed code violations to go uncorrected for two years needs to be revisited. Many inspectors view their daily work in a way that results in the low hanging fruit getting picked, but the more difficult to reach fruit on high branches going untouched. When an agency is responsible for inspections for compliance with safety, health, fire and/or environmental standards there needs to be a meaningful quality control or improvement program in place. Citizens or your community deserve no less.

See More

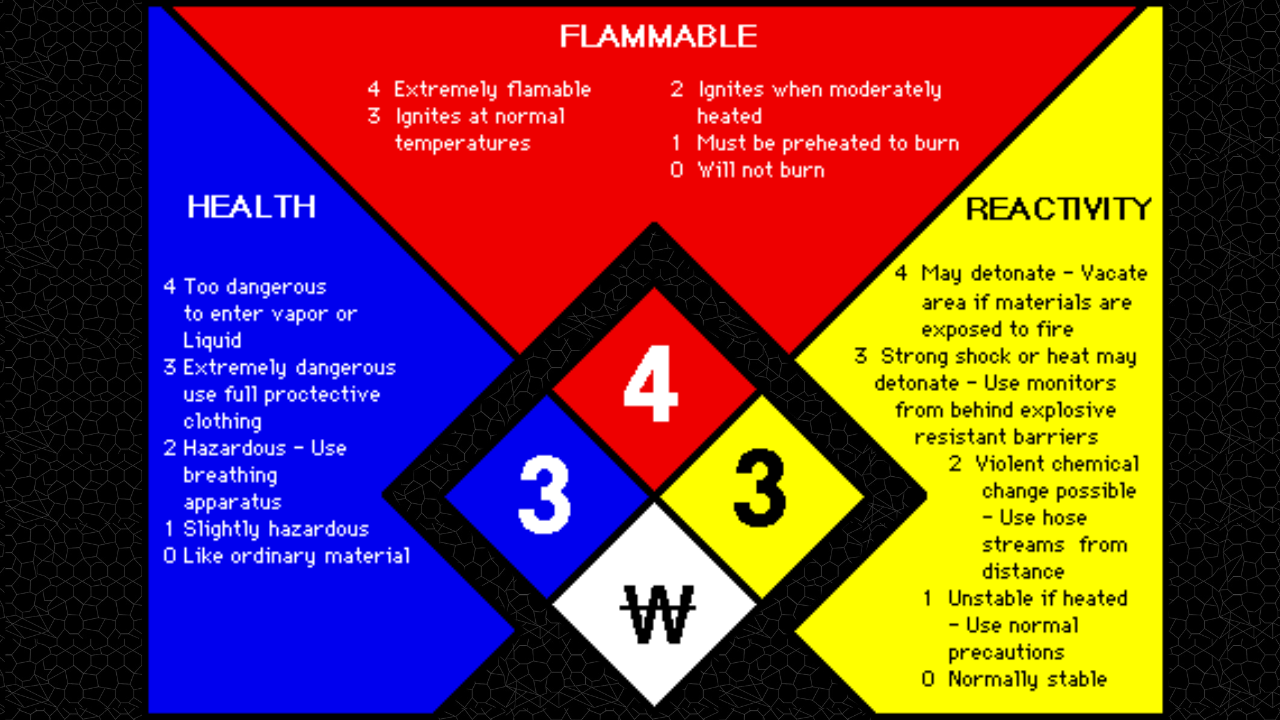

The National Fire Prevention Association (NFPA) developed a rating system to identify and rank the hazards of a material. If you have previously worked in construction you’ve probably seen the colorful labels used to explain these hazards. The NFPA's hazard rating is diamond-shaped, made up of four smaller diamonds. The NFPA symbol colors are blue, red, yellow and white. Inside the colored smaller diamonds are numbers or symbols loaded with a wealth of knowledge.

The National Fire Prevention Association (NFPA) developed a rating system to identify and rank the hazards of a material. If you have previously worked in construction you’ve probably seen the colorful labels used to explain these hazards. The NFPA's hazard rating is diamond-shaped, made up of four smaller diamonds. The NFPA symbol colors are blue, red, yellow and white. Inside the colored smaller diamonds are numbers or symbols loaded with a wealth of knowledge.

See More

ISO 12100 is a fundamental safety standard being developed that will apply to a very broad array of machinery. There are many machines that have specific industry consensus standards that pertain to the particular equipment (e.g., power presses, robots, packaging machinery). There are many more machines for which no industry specific standard exists. In this case, the ISO “A level” standard ISO 12100 Safety of Machinery applies. Complying with the requirements of ISO 12100 is a critical first step in achieving mobility of equipment and consistent operations.

ISO 12100 is a fundamental safety standard being developed that will apply to a very broad array of machinery. There are many machines that have specific industry consensus standards that pertain to the particular equipment (e.g., power presses, robots, packaging machinery). There are many more machines for which no industry specific standard exists. In this case, the ISO “A level” standard ISO 12100 Safety of Machinery applies. Complying with the requirements of ISO 12100 is a critical first step in achieving mobility of equipment and consistent operations.

See More