Do You Need NFPA 70E?

By John C. Klingler, P.E., Lewellyn Technology, Inc.

One of the hot topics in electrical and mechanical training classes is the NFPA 70E. Students question what 70E is and how it relates to the National Electrical Code (NEC), if 70E is a new regulation and if not why are they just now hearing about it, and if companies are required to comply with 70E.

This article will take some of the mystery out of 70E.

What is 70E?

Parts of 70E have been around since 1979. The Occupational Safety and Health Administration (OSHA) adopted new regulations on safe electrical work practices in 1990 based on 70E. However, 70E is a topic of interest now because the NEC and OSHA are referring to it in their documents, and citations are now being written based on 70E.

With the passing of the Williams-Steiger Occupational Safety and Health Act of 1970 came the need for occupational safety and health regulations. Congress directed OSHA to develop new regulations using existing “national consensus standards” and established federal standards.

Troubleshooting live equipment, such as testing a contactor (top), requires hazard/risk level 2 PPE, suitable for protection from an arc flash of 8 cal/cm2, but racking of a circuit breaker (bottom) demands hazard/risk level 3 PPE, suitable for protection from an arc flash of 25 cal/cm2.

For electrical safety regulations it originally adopted the most widely accepted electrical standard in the world—the NEC (National Fire Protection Association’s Standard NFPA 70). However, OSHA encountered several problems in attempting to use the latest editions of the NEC:

• With each new update of the NEC (which occurs every 3 years) OSHA had to go through the extensive legal process of adopting the new NEC edition and risk creating potential conflicts between the adopted version and the published version.

• OSHA needed a regulation that addressed installation, operation, maintenance, and repair in the workplace. The NEC is an electrical installation standard only.

• Because the purpose of the NEC is the practical safeguarding of persons and equipment and because it includes provisions for residential, it contains many provisions that are not relevant to OSHA and only confuse the reader.

To correct these problems and others, NFPA created a committee to develop electrical safety standards that would serve the needs of OSHA. This committee reports through the NEC technical committee and is called the Committee on Electrical Safety Requirements for Employee Workplaces—NFPA 70E. This standard has evolved over time:

• 1979: First edition published with only Part I (Installation Safety Requirements).

• 1981: Second edition added Part II (Safety-Related Work Practices).

• 1983: Third edition added Part III (Safety-Related Maintenance Requirements).

• 1988: Fourth edition had only minor revisions.

• 1995: Fifth edition updated Part I based on the most recent NEC and made some major additions to Part II.

• 2000: Sixth edition updated Part I based on the most recent NEC, made additions to Part II, and added Part IV (Safety Requirements for Special Equipment).

• 2004: The most recent edition made many significant changes including a total reorganization into the NEC format. In the reorganization Part II was moved to become Chapter 1, Part III became Chapter 2, Part IV became Chapter 3, and Part I became Chapt. 4.

Is 70E a “national consensus standard”?

By definition NFPA 70E is a national consensus standard. In 29 CFR 1910.2(g), a national consensus standard is defined as a standard that is developed by the same persons it affects and then is adopted by a nationally recognized organization.

Organizations that publish national consensus standards include the NFPA, American Society for Testing and Materials (ASTM), and the American National Standards Institute (ANSI).

What does it cover?

In NFPA’s catalog it states: “70E covers the full range of electrical safety issues from safety-related work practices to maintenance, special equipment requirements, and installation. In fact, OSHA bases its electrical safety mandates—OSHA 1910 Subpart S and OSHA 1926 Subpart K—on the comprehensive information in this important Standard.”

The 2004 edition of 70E has an introduction, four chapters, and 13 annexes.

Chapter 1, “Safety-Related Work Practices,” is the meat of the 70E document. It discusses qualified vs unqualified persons and training. It requires an electrical safety program, electrical hazard analysis for shock and arc flash, energized electrical work permits, and lockout/tagout procedures. It establishes approach boundaries and discusses how to select appropriate personal protective equipment (PPE) and protective clothing. Arc flash protection also is addressed in this chapter.

Chapter 2, “Safety-Related Maintenance Requirements,” does not create much discussion. It basically requires that electrical components, wiring, and equipment be maintained in a safe condition.

Chapter 3, “Safety Requirements for Special Equipment,” covers batteries, lasers, and power electronic equipment. This chapter affects more installations than one might initially think because power electronic equipment includes electric arc welding equipment, and motor drives, UPS, and lighting controllers that contain rectifiers and inverters. There are no surprises in this chapter but those with the subject equipment should review it.

Chapter 4, “Installation Safety Requirements,” is a truncated version of the NEC. Here authors state that the requirements in Chapter 4 are based on the NEC and in the forward of the 70E document it states that this document is not intended to be used in lieu of the NEC.

Annexes A through M offer useful information including how to calculate flash protection boundaries.

What is the “general duty clause” and how does it relate to compliance?

This clause refers to a portion of the Occupational Safety and Health Act of 1970:

5. Duties

(a) Each employer

(1) shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees,

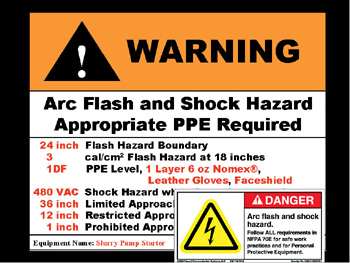

The NEC requires field labeling (above) on equipment where arc flash is a hazard. A future edition of the code may require more extensive labeling (inset) that includes flash hazard boundary and PPE levels.

Section 5(a)(1) has become known as the “general duty clause.” It is a catch-all for citations if OSHA identifies unsafe conditions to which a regulation does not exist.

In practice, OSHA, court precedent, and the review commission have established that if the following elements are present, a “general duty clause” citation may be issued:

• The employer failed to keep the workplace free of a hazard to which employees of that employer were exposed.

• The hazard was recognized. (Examples might include through safety personnel, employees, organization, trade organization, or industry customs.)

• The hazard was causing or was likely to cause death or serious physical harm.

• There was a feasible and useful method to correct the hazard.

Is compliance mandatory?

In 2002, the NEC referenced NFPA 70E for the first time.

NFPA 70-NEC Section 110.16 Flash Protection requires field labeling of switchboards, panelboards, industrial control panels, and motor control centers that are likely to require examination, adjustment, servicing, or maintenance while energized to warn the qualified person of the potential of an arc flash. In Fine Print Note No. 1 that follows 110.16 it refers the reader to NFPA 70E for assistance in determining severity of potential exposure, planning safe work practices, and selecting personal protective equipment.

It is possible and in fact likely that the 2005 NEC may strengthen the language in 110.16 to require specific information on the field labels such as flash boundaries and PPE requirements, which are addressed in 70E. If this happens, facilities complying with the 2005 NEC will need flash hazard analyses completed for all new equipment or will need to default to generic tables provided in 70E to determine the boundaries and PPE requirements.

OSHA regulation 29 CFR 1910 Subpart S Appendix A: Reference Documents also references NFPA 70E:

“The following references provide information which can be helpful in understanding and complying with the requirements contained in Subpart S:

NFPA 70-78 National Electrical Code

NFPA 70E Standard for the Electrical Safety Requirements for Employee Workplaces”

In a “Standards Interpretation” letter from OSHA in 2003 the following is from selected paragraphs:

“All your questions involve the NFPA 70E standard, which is one of many industry consensus standards developed by the National Fire Protection Association. NFPA 70E, which is titled ‘Electrical Safety Requirements for Employee Workplaces,’ is the NFPA’s consensus standard for workplace electrical safety. It covers employee protection from electrical hazards including shock, arc blasts, explosions initiated by electricity, outside conductors, etc.

“With respect to the General Duty Clause, industry consensus standards may be evidence that a hazard is ‘recognized’ and that there is a feasible means of correcting such a hazard.

“These provisions (1910.132(a) personal protective equipment) are written in general terms, requiring, for example, that personal protective equipment be provided ‘where necessary by reason of hazards…’ and requiring the employer to select equipment ‘that will protect the affected employee from the hazards…’.

“Industry consensus standards, such as NFPA 70E, can be used by employers as guides to making the assessments and equipment selections required by the standard. Similarly, in OSHA enforcement actions, they (70E) can be used as evidence of whether the employer acted reasonably.

“Under 1910.135, the employer must ensure that affected employees wear a protective helmet that meets either the applicable ANSI Z89.1 standard or a helmet that the employer demonstrates ‘to be equally effective’. If an employer demonstrated that NFPA 70E contains criteria for protective helmets regarding protection against falling objects and electrical shock that is equal to or more stringent than the applicable ANSI standard, and a helmet met the NFPA 70E criteria, the employer could use that to demonstrate that the helmet is ‘equally effective’.”

In September 1999 a major U. S. corporation experienced an electrical accident that resulted in serious burn injuries to an electrical apprentice employee. OSHA investigated the accident and issued a number of citations. The employer challenged the citations and the disagreement ended up before the Occupational Safety and Health Review Commission.

As part of the citation OSHA contended that the employer violated a federal regulation because it did not provide or require that its electricians wear appropriate flame-resistant or retardant personal protection, specifically, flame-resistant coveralls and insulated gloves. OSHA also contended that the employer violated a regulation when it did not provide or require that its electricians wear appropriate face protection.

In the settlement the employer agreed to develop hazard analyses in accordance with the personal protective equipment provisions contained in NFPA 70E. OSHA agreed that given the present state of its standards and regulations, the hazard analyses would achieve compliance with its requirements.

Points to remember

To summarize, you should understand:

• Several of the OSHA regulations are written in general terms leaving the details up to the employer on how to comply. (An example is requirements for personal protective equipment and clothing in 1910.132(a).) The employer is expected to use consensus standards to help in the selection of the best method to achieve compliance with OSHA regulations. NFPA 70E is a “how to comply” standard for specific OSHA regulations.

• Although NFPA developed 70E for OSHA, OSHA has not officially adopted or incorporated it by reference into its regulations. Instead in 1990, OSHA promulgated new safety-related work practices in 1910.331 based on the information in 70E at that time. However, NFPA has made major changes to 70E based on better information and research since OSHA developed its standard. The bottom-line is that 70E is not a federal regulation; it is just a national consensus standard like hundreds of other standards that are not laws or regulations. But compliance with 70E will assure compliance with specific OSHA electrical regulations.

• Some OSHA state plans are more restrictive than federal OSHA and as such may have adopted or incorporated 70E; however, this is on a state-by-state basis and should be evaluated by employer location. After researching several states on this issue, the responses were too varied to incorporate into this article.

• In the event of an injury or death due to an electrical accident, if OSHA determines that compliance with 70E would have prevented or lessened the injury, OSHA may cite the employer under the “general duty clause” for not using 70E to protect the employee(s). (Shock and arc flash are recognized hazards that employers should be aware of because 70E is now referenced in both the NEC and OSHA regulations.)

• It is important to get training on NFPA 70E and to implement it into your electrical safety program.

Related Articles

Elastopipe: Safety Pipe for Oil Rigs

CSA Launches First Confined Spaces Standard in Canada

All About Eye Protection

Eye Injuries are a Serious Threat to American Workers

11 Tips for Effective Workplace Housekeeping

The Joined Cybersecurity and Data Integrity Framework for Maintenance