Preventive vs. Reactive Maintenance: Don’t Neglect Makeup Water and Condensate Return Treatment – Part 2

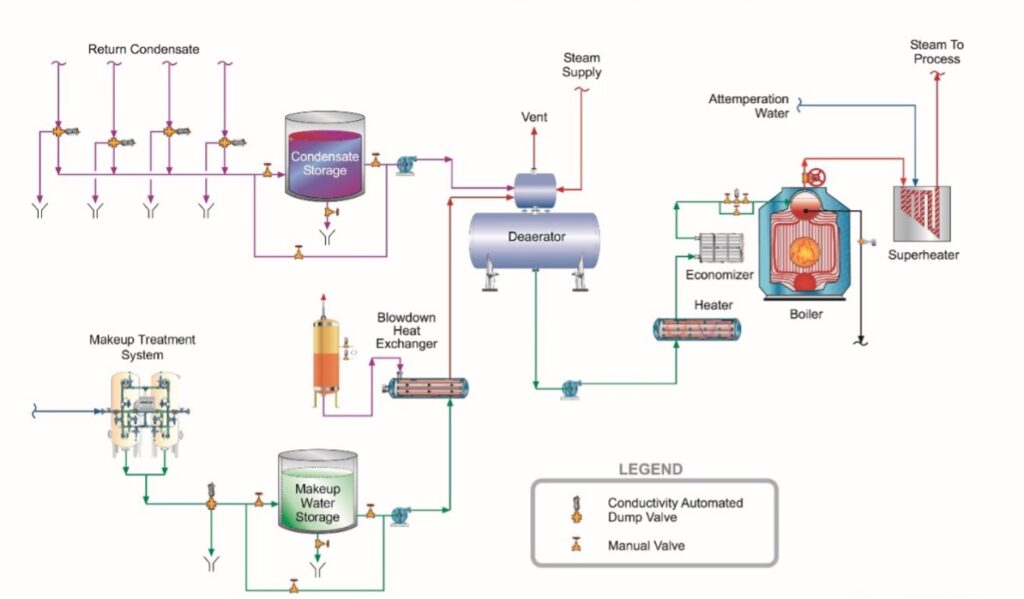

Many impurities may transport to boilers via contaminated condensate return. Boiler tube and steam system failures are usually much more costly than preventive installation of treatment equipment and chemistry programs. This article touched upon only some of the important condensate return issues, but will hopefully galvanize readers to focus on these critical topics.